Sulfur bearing steel electro-slag remelting process

A technology of electroslag remelting and sulfur-containing steel, which is applied in the field of electroslag metallurgy, can solve the problems of excessive burning loss of components, large fluctuations in sulfur component control, unstable recovery rate of sulfur content, etc., and achieve the effect of reducing burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

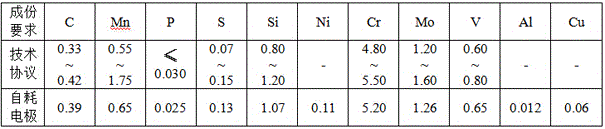

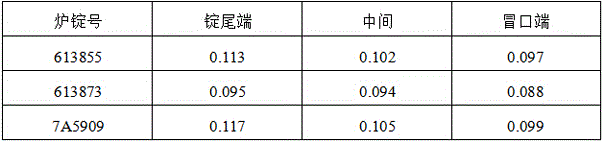

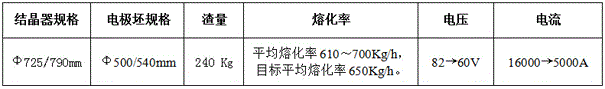

[0014] An electroslag remelting process for sulfur-containing steel, electroslag remelting H11S steel, the production parameters of the chemical composition are shown in Table 1, and the production parameters are shown in Table 2. The melting point of this steel is about 1470°C, and the slag system used for electroslag remelting is ternary slag: CaF 2 : SiO 2 : CaO=45:30:25 (weight ratio), the slag melting point is 1190°C. Before the slag is used, the fluorite is baked at 600°C for 4 hours, then kept at 200°C, and taken as needed; the silica powder and lime block are baked at 680°C for 4 hours, kept at 200°C, and taken as needed. Pick. Graphite electrodes are used to start the arc coldly. When adding slag, fluorite powder is added first. After the fluorite powder is added to form a slag pool, silica powder and lime blocks are alternately and slowly added to prevent the slag from completely covering the furnace. Add iron sulfide once every 10 minutes during the slagging proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com