Genetically engineered bacteria of high-yield malto-oligosaccharide-based trehalose-hydrolyzing enzyme and application of genetically engineered bacteria

A trehalose hydrolase and malto-oligosaccharide-based technology, which is applied in the fields of genetic engineering and fermentation engineering, can solve the problems of low enzyme activity, low soluble expression, unfavorable industrial application and the like, and achieve the effect of improving soluble expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

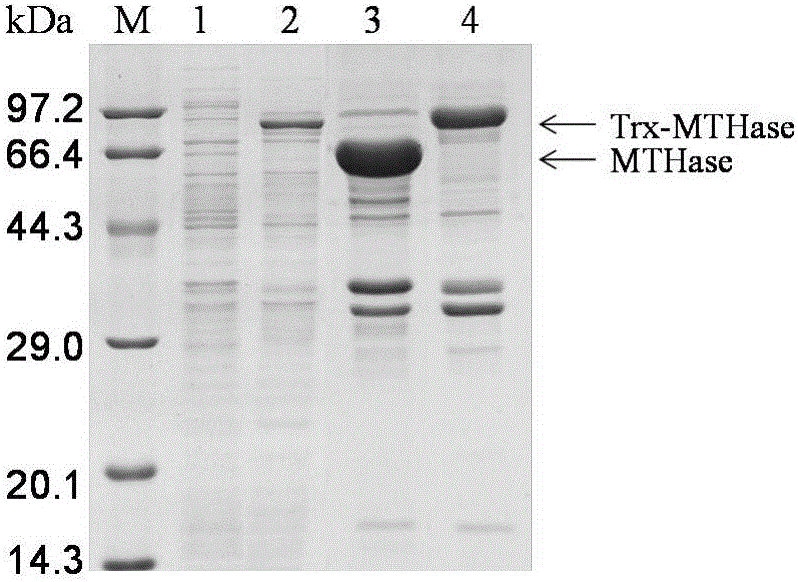

[0034] Example 1: Construction of pET-32a(+)-treZ / E.coli Origami(DE3)

[0035] PCR amplified maltooligosaccharide-based trehalose hydrolase gene treZ (nucleotide sequence is SEQ ID NO.1), and the obtained treZ gene fragment was digested and purified with EcoR I and Hind III vector pET-32a ( +), ligated with T4DNAligase at 4°C for 16h. The ligation product was transformed into the cloning host E.coli JM109 and coated with LB solid medium (containing 100 μg·mL -1 ampicillin), cultivated in a 37°C incubator for 8 hours, picked a single colony, and passed through LB liquid medium (containing 100 μg·mL -1 ampicillin) at 37°C for 8 hours, the plasmids were extracted from the cells, verified by enzyme digestion, and then the DNA sequence of the verified recombinant plasmids was determined to obtain the recombinant plasmid pET-32a(+)-treZ. The pET-32a(+) vector contains a thioredoxin (TrxA) fusion tag. Thioredoxin (thioredoxin A, TrxA) is a small molecule protein with a conserved se...

Embodiment 2

[0040] Example 2 Shake flask fermentation to produce enzyme

[0041] 1. The recombinant pET-24a(+)-treZ / E.coliBL21(DE3) and pET-32a(+)-treZ constructed with pET-24a(+) as the vector and E.coli BL21(DE3) as the host / E.coli Origami(DE3), use a pipette gun to draw 10 μl of the bacterial solution and inoculate it into 10 mL of LB liquid medium (adding a final concentration of 30 μg·mL -1 Kanamycin or 100 μg·mL -1 Ampicillin), placed in a constant temperature shaker at 37°C, 200r·min -1 , cultivated for 8-10h, as the seed solution.

[0042] Inject the cultivated seed solution into 40 mL TB medium with a 4% inoculum size (adding a final concentration of 30 μg·mL -1 Kanamycin or 100 μg·mL -1 Ampicillin), placed in a constant temperature shaker at 37°C, with a rotation speed of 200r min -1 , cultivated for 2h; add the final concentration of 0.05-0.4mmol L -1 IPTG, 25°C, speed 200r·min- 1 , cultivated for 24-48h. Centrifuge the fermentation broth to remove the supernatant, col...

Embodiment 3

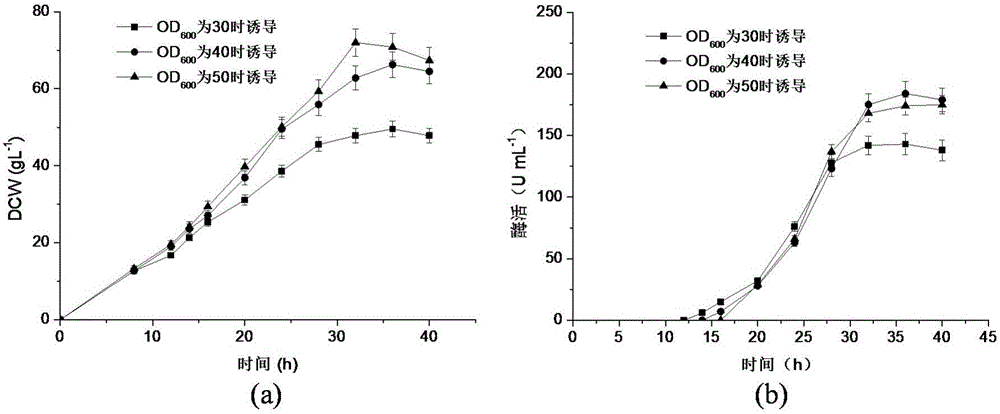

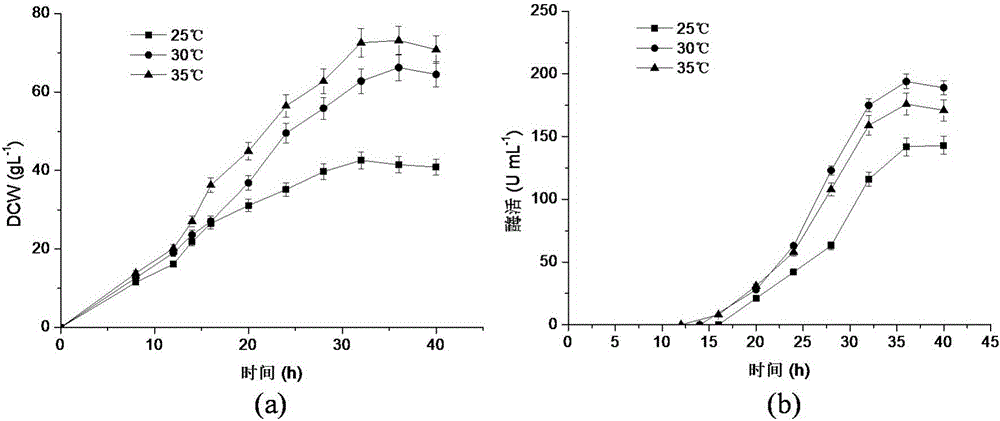

[0051] Example 3 Effects of Different Induction Times on the Fermentation and Enzyme Production of Recombinant Bacteria

[0052] 1. Seed culture: Inoculate the pET-32a(+)-treZ / E.coli Origami(DE3) strain stored in a glycerol tube at -80°C into the seed medium, and cultivate it on a constant temperature shaker at a temperature of 37°C and a rotation speed of 200rpm , cultivated for 8h.

[0053] 2. Enzyme production by fermentation:

[0054] The seed solution was added to the fermentation medium with an inoculum of 8%. The dissolved oxygen was maintained at 30% by controlling the stirring speed and ventilation rate, the temperature was controlled at 37° C., and the pH was controlled at 7.0 by feeding 25% (v / v) ammonia water. After the initial glycerin is consumed and the dissolved oxygen rises to 80-100%, the batch fermentation culture ends. With specific growth rate μ=0.2h -1 The feed medium was added exponentially. Select in bacterial concentration OD 600 When reaching 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com