A nickel-plated copper-silver alloy conductor high temperature resistant cable and its manufacturing method

A technology of silver alloy and nickel-plated copper, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductors, etc., can solve the problems that silver-plated copper conductors cannot be used for a long time, copper conductors are brittle, and distribution lines are short-circuited. Achieve good high temperature oxidation resistance, acid and alkali corrosion resistance, good electrical insulation performance, safe and reliable work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

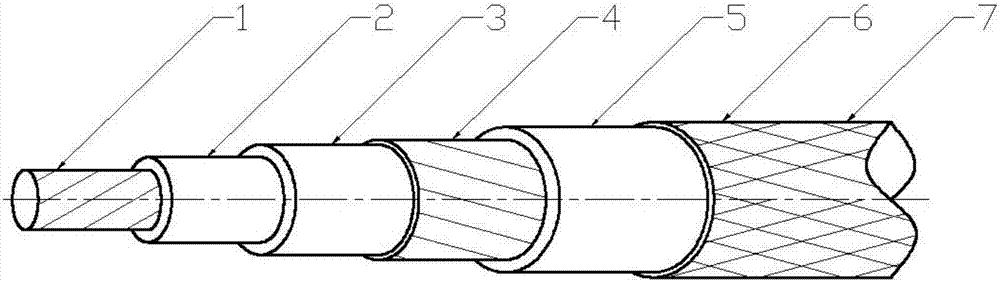

[0021] See figure 1 , a nickel-plated copper-silver alloy conductor high-temperature-resistant cable in this embodiment: from the inside to the outside, the conductor 1, the polytetrafluoroethylene insulating layer 2, the polyimide insulating layer 3, the alkali-free glass filament winding layer 4, the second A polytetrafluoroethylene emulsion coating, a polytetrafluoroethylene film sheath layer 5, an alkali-free glass fiber tetrafluoro wire braid layer 6 and a second polytetrafluoroethylene emulsion coating 7; the conductor 1 is made of a plurality of nickel-plated Copper-silver alloy wire twisted. The polytetrafluoroethylene insulating layer 2 and the polyimide insulating layer 3 are melted and bonded together.

[0022] The manufacturing method is:

[0023] Step 1: Manufacture conductor 1: Melt the copper-silver alloy at a temperature of 1120±20°C. The silver content in the copper-silver alloy conductor is 0.05-0.08%. The molten copper melted at high temperature is cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com