A simple method to improve the cycle stability of carbon-sulfur composite lithium-sulfur cathode

A cycle stability and carbon-sulfur composite technology, applied to battery electrodes, lithium batteries, structural parts, etc., can solve the problems of reducing S utilization rate, complicated procedures, and high cost, so as to suppress the impact of capacity and improve cycle performance , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

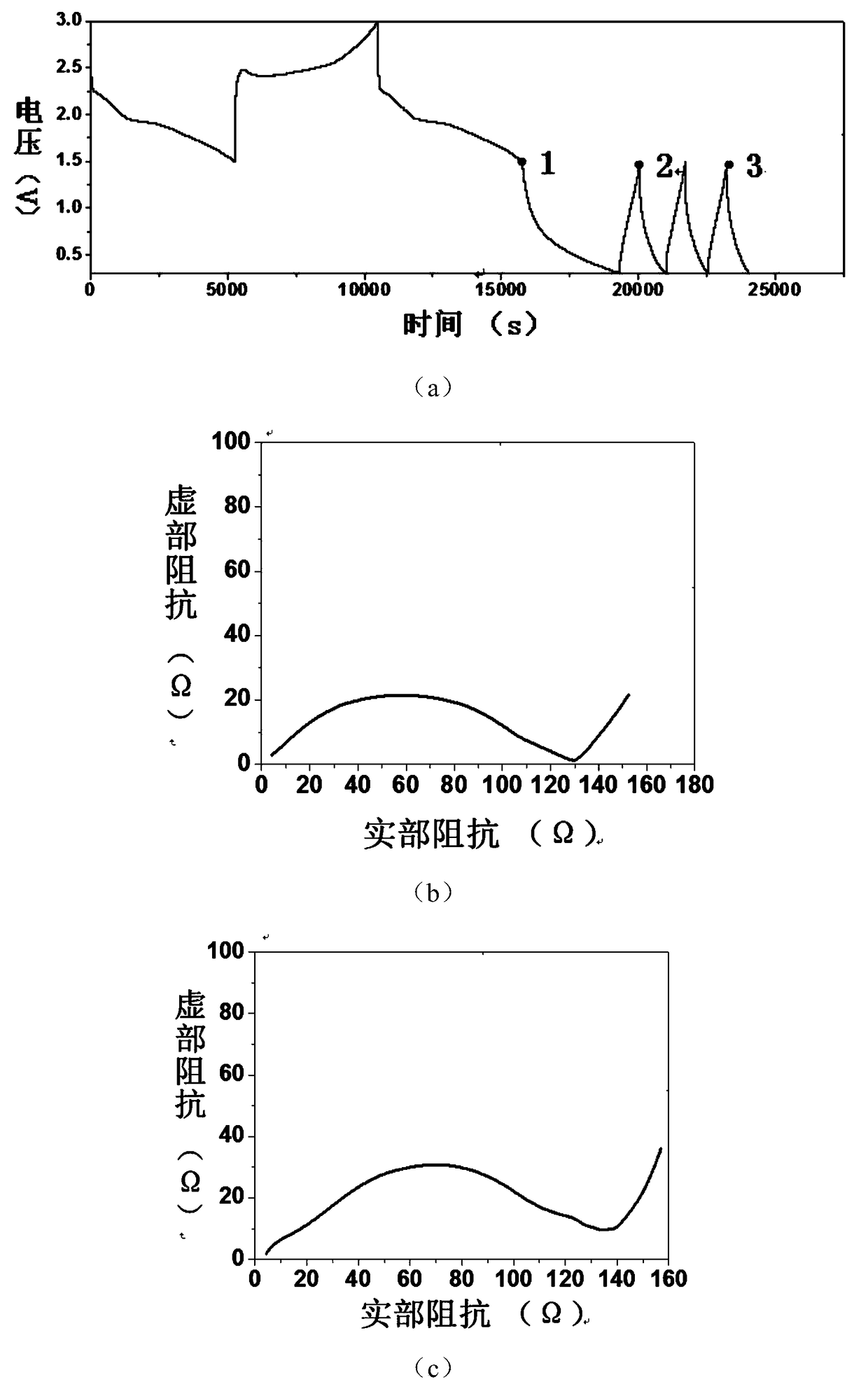

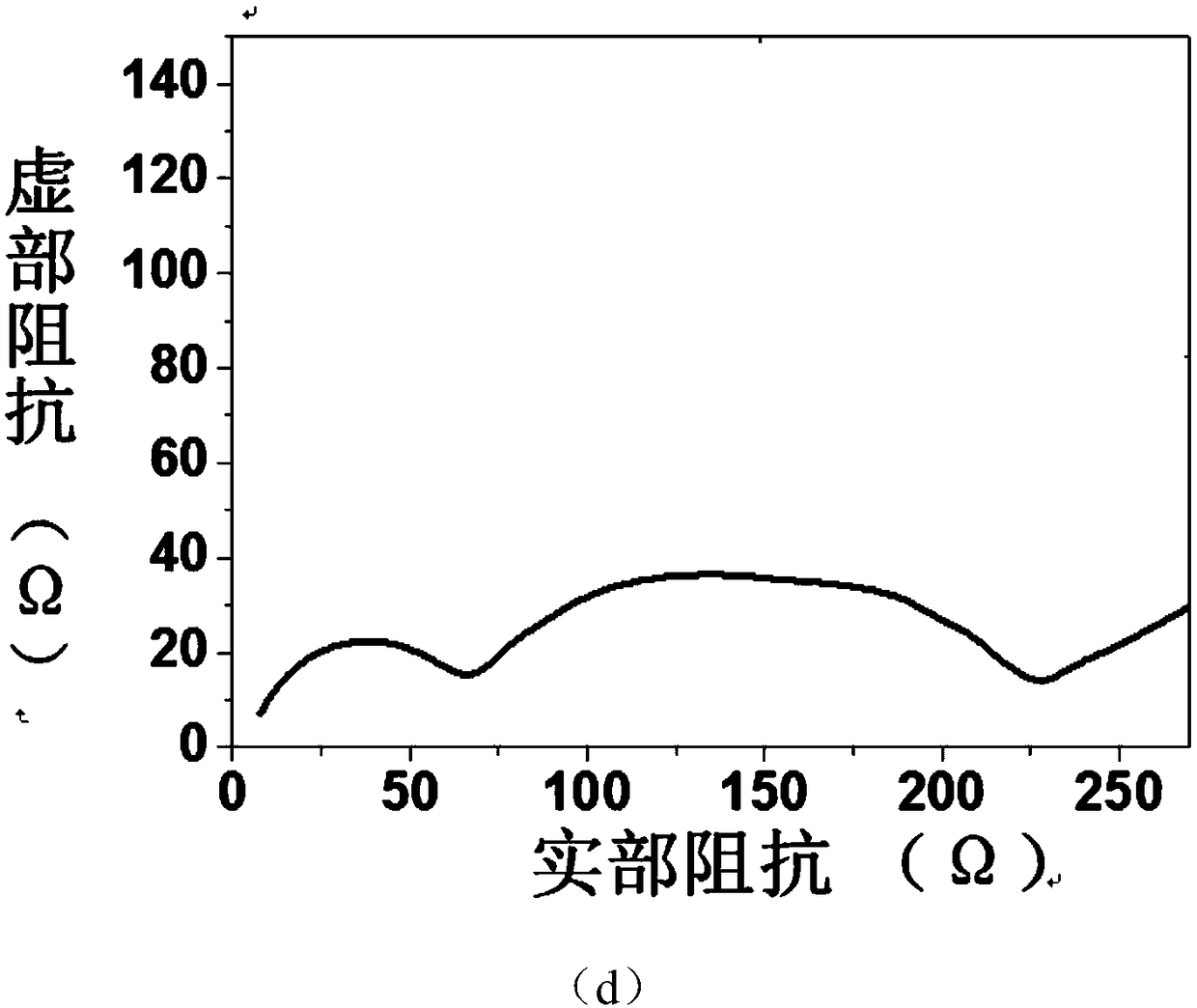

Embodiment example 1

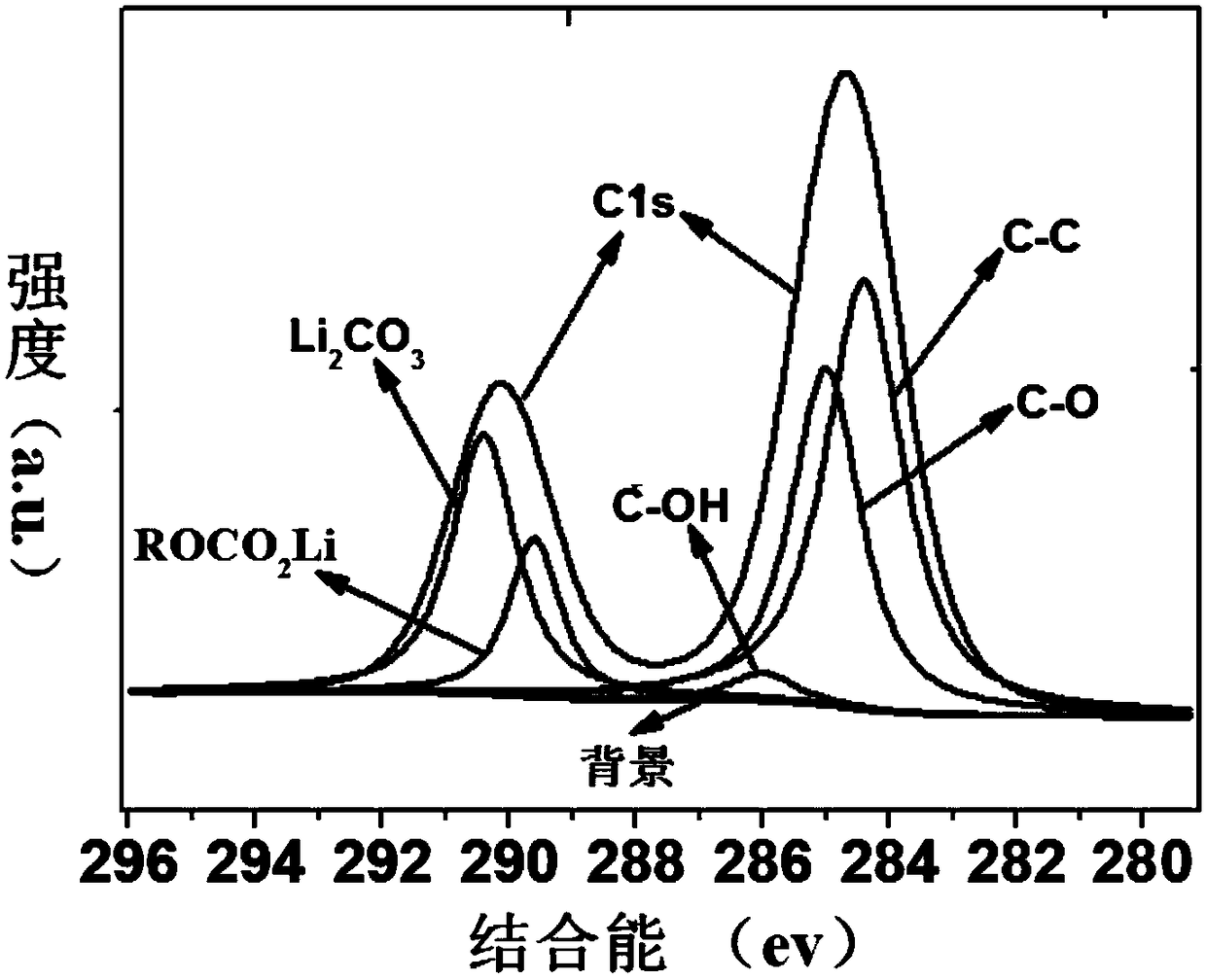

[0019] 1) Preparation of core-shell structure carbon / sulfur composite cathode materials

[0020] Add 1.4ml of ammonia water, 55ml of ethanol, 140ml of deionized water, 1.3g of resorcinol, and 1.3g of CTAB into a round bottom flask and stir for 30min. Then add 7.0ml TEOS and 2.0ml formaldehyde, stir at room temperature for 24h, then stand in an oil bath at 100°C for 24h. The reaction product was obtained by suction filtration, dried in a thermostat at 70°C for 12 hours, and the dried product was carbonized at 700°C for 3 hours under the protection of nitrogen, and the obtained product was further etched in 4mol / L NaOH at 80°C for 10 hours to remove SiO 2 ball. The porous hollow carbon spheres obtained after washing the etched product (removing NaOH) and suction-filtering and drying are carbon materials.

[0021] Grind 0.1 of the prepared carbon material and 0.23 g of sublimed sulfur in an agate ball mill to obtain a carbon-sulfur mixture, which is then placed in an ampoule an...

Embodiment example 2

[0032] 1) Preparation of carbon nanotube / sulfur composite cathode material 1:1.4~2.9

[0033] Grind 0.1 of the prepared commercial carbon nanotubes and 0.14 of the sublimated sulfur in an agate ball mill to obtain a carbon-sulfur mixture, which is then placed in an ampoule and melted and sealed with an alcohol blowtorch. The sealed ampoule was placed in a vacuum drying oven, and calcined at 155° C. for 5 hours to obtain a lithium-sulfur battery positive electrode material with a porous core-shell structure sulfur-carbon composite material.

[0034] 2) Preparation of core-shell structure carbon / sulfur composite cathode sheet

[0035] Dissolve the prepared lithium-sulfur battery cathode material, carbon black (conductive agent) and PVDF (binder) in an appropriate amount of NMP according to the mass ratio of 8:1:1 and mix uniformly to prepare the cathode slurry, and coat the cathode with a coating machine. The slurry is coated on the aluminum foil current collector, dried in vac...

Embodiment example 3

[0039] 1) Preparation of graphene / sulfur composite cathode material

[0040]0.1 prepared commercial graphene, 0.29 sublimated sulfur, and ground in an agate ball mill to obtain a carbon-sulfur mixture, which was then placed in an ampoule, melted and sealed with an alcohol blowtorch. Put the sealed ampoule bottle into a vacuum drying oven, and calcinate at 155° C. for 8 hours to obtain a lithium-sulfur battery cathode material with a porous core-shell structure sulfur-carbon composite material.

[0041] 2) Preparation of core-shell structure carbon / sulfur composite cathode sheet

[0042] Dissolve the prepared lithium-sulfur battery positive electrode material, carbon black (conductive agent) and PVDF (binder) in an appropriate amount of NMP according to the mass ratio of 8:1:1 and mix them evenly to prepare positive electrode slurry, and use a coating machine to coat the positive electrode The slurry is coated on the aluminum foil current collector, dried in vacuum at 80°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com