Repairing type silk mask and preparation method thereof

A facial mask and silk technology, applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve problems such as hazards and many chemical components, and achieve the effects of preventing allergies, itching, whitening the skin, and eliminating fine lines on the face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

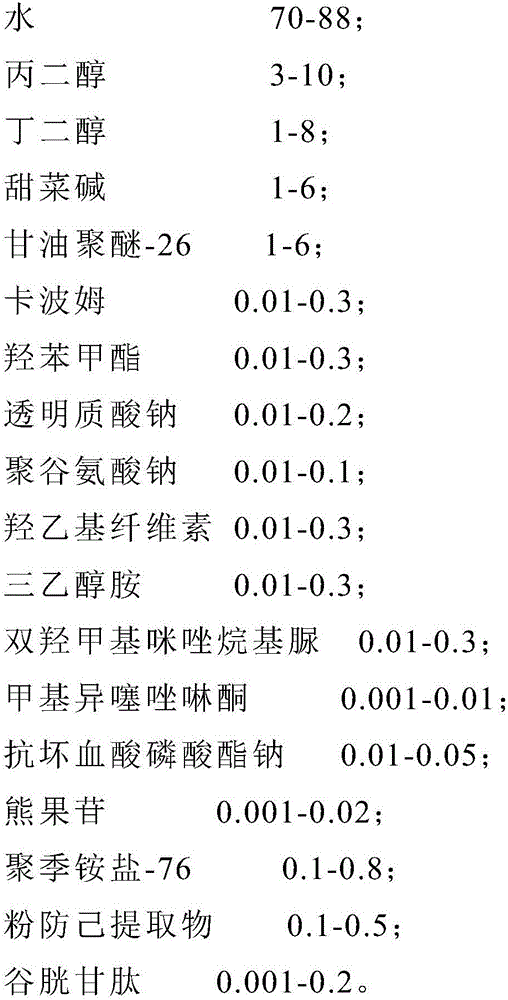

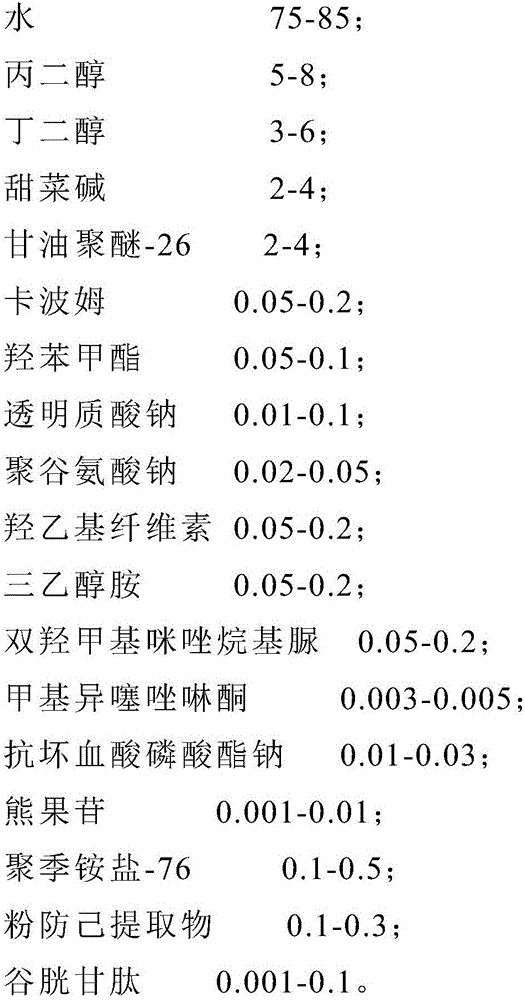

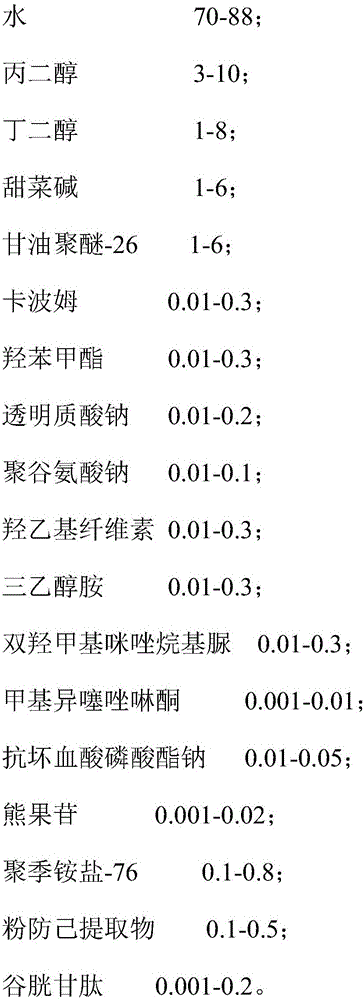

Method used

Image

Examples

Embodiment 1

[0038] Add 81.31wt% water, 7.6wt% propylene glycol, 4wt% butanediol, 2.6wt% betaine and 3.2wt% glyceryl polyether-26 to the emulsification pot, stir well, the stirring speed is 25 rpm, start homogenization ;Add 0.08wt% sodium hyaluronate, 0.15wt% carbomer, 0.05wt% polyglutamate sodium and 0.12wt% hydroxyethyl cellulose, homogenize for 10 minutes, stir until there is no particle agglomeration , start heating, heat to 85°C, keep warm for 25 minutes, then add 0.08wt% methylparaben, stir and dissolve evenly, and set aside;

[0039] Turn on the cooling water and start to cool down. When the temperature drops to 60°C, add 0.1wt% triethanolamine and stir to dissolve evenly. The stirring speed is 25 rpm. Keep warm and vacuumize to defoam. After no bubbles, continue to cool down and stir for 5 minutes to disperse the material. Evenly, continue to cool down;

[0040] Cool down to 45°C, add 0.02wt% sodium ascorbyl phosphate, 0.006wt% arbutin, 0.32wt% polyquaternium-76, 0.234wt% Tetragal...

Embodiment 2

[0043] Add 82.17wt% water, 6.5wt% propylene glycol, 5.3wt% butanediol, 3wt% betaine and 2.3wt% glyceryl polyether-26 to the emulsification pot, stir evenly, the stirring speed is 25 rpm, start homogenization Add 0.04wt% sodium hyaluronate, 0.08wt% carbomer, 0.05wt% sodium polyglutamate and 0.06wt% hydroxyethyl cellulose, homogenize for 10 minutes, and stir until there is no particle agglomeration , start heating, heat to 85°C, keep warm for 25 minutes, then add 0.05wt% methylparaben, stir and dissolve evenly, and set aside;

[0044] Turn on the cooling water and start to cool down. When the temperature drops to 60°C, add 0.07wt% triethanolamine and stir to dissolve evenly. The stirring speed is 25 rpm. Keep warm and vacuumize to defoam. After no bubbles, continue to cool down and stir for 5 minutes to disperse the material. Evenly, continue to cool down;

[0045] Cool down to 45°C, add 0.026wt% sodium ascorbyl phosphate, 0.004wt% arbutin, 0.32wt% polyquaternium-76, 0.18wt% Te...

Embodiment 3

[0048] Add 79.46wt% water, 7.6wt% propylene glycol, 5wt% butanediol, 3.4wt% betaine and 3.4wt% glyceryl polyether-26 to the emulsification pot, stir evenly, the stirring speed is 25 rpm, start homogenization ;Add 0.08wt% sodium hyaluronate, 0.15wt% carbomer, 0.05wt% polyglutamate sodium and 0.013wt% hydroxyethyl cellulose, homogenize for 10 minutes, stir until there is no particle agglomeration , start heating, heat to 85°C, keep warm for 25 minutes, then add 0.08wt% methylparaben, stir and dissolve evenly, and set aside;

[0049] Turn on the cooling water and start to cool down. When the temperature drops to 60°C, add 0.07wt% triethanolamine and stir to dissolve evenly. The stirring speed is 25 rpm. Keep warm and vacuumize to defoam. After no bubbles, continue to cool down and stir for 5 minutes to disperse the material. Evenly, continue to cool down;

[0050] Cool down to 45°C, add 0.01wt% sodium ascorbyl phosphate, 0.008wt% arbutin, 0.32wt% polyquaternium-76, 0.18wt% Tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com