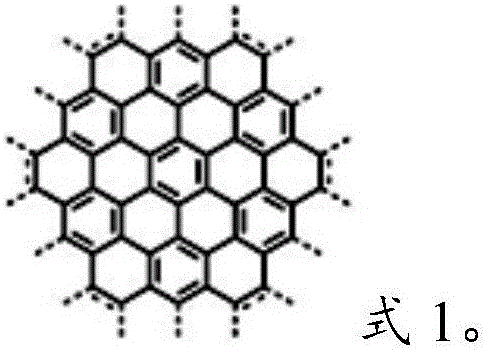

Graphene adsorption material, preparation method and application thereof and cigarette filter

An adsorption material, graphene technology, applied in the field of adsorption, can solve the problems of reducing the content of benzopyrene, the preparation process is cumbersome, the adsorption effect of benzopyrene needs to be improved, etc., and achieves the effects of reducing smoking hazards and preventing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The fiber that adopts the preparation method in the prior art to make is illustrated as follows:

[0043] Taking the preparation of viscose fiber as an example, the viscose liquid used in the present invention is a well-known viscose liquid in the prior art. , aging, filtration, defoaming and other processes. The pulp is impregnated with an aqueous sodium hydroxide solution with a concentration of about 18%, so that the cellulose is converted into alkali cellulose, the hemicellulose is dissolved, and the degree of polymerization is partially reduced; then the excess alkali is removed by pressing. The blocky alkali cellulose becomes loose flocs after crushing on the pulverizer, and the uniformity of subsequent chemical reactions is improved due to the increase in surface area. Oxidative cracking of alkali cellulose under the action of oxygen reduces the average degree of polymerization. This process is called aging. After aging, the reaction of alkali cellulose and car...

preparation example 1

[0143] (1) Under the action of ferrous chloride, the corn cob cellulose is subjected to catalytic treatment to obtain a precursor;

[0144] (2) under the condition of nitrogen, the precursor is kept at 150° C. for 2 hours to obtain the first intermediate;

[0145] (3) under the condition of nitrogen, the temperature of the first intermediate is raised to 400° C. for 3.5 hours to obtain the second intermediate;

[0146] (4) under the condition of nitrogen, the temperature of the second intermediate is raised to 1200° C. for 3 hours to obtain the third intermediate;

[0147] (5) After the third intermediate is acid-washed with 10wt% sodium hydroxide solution, 4wt% hydrochloric acid and washed with water, the biomass graphene is obtained;

[0148] The heating rate in the steps (3) and (4) is 15° C. / min˜16° C. / min.

[0149] Detected by XRD, in the biomass graphene prepared in Preparation Example 1 of the present invention, the content of mineral elements is 4wt% of the biomass g...

preparation example 2

[0151] Prepare biomass graphene by the method identical with preparation example 1, difference is: the catalyst used in step (1) is the mixture (mass ratio is 3:1) of ferric chloride and nickel nitrate, and biomass carbon source is Corn cob cellulose bleached with hydrogen peroxide; the protective gas used in steps (2)-(4) is argon, the precursor is kept at 140°C for 2.5h, the temperature of the first intermediate is raised to 250°C for 4h, and the second intermediate The temperature of the body was raised to 1100° C. for 2 h; the alkali used in step (5) was 5 wt % NaOH aqueous solution, and the acid used was 3 wt % hydrochloric acid aqueous solution.

[0152] After testing, in the biomass graphene prepared in Preparation Example 2 of the present invention, the content of mineral elements is 2wt% of the biomass graphene; and, the mineral elements in the biomass graphene mainly include Si, Al, Fe elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com