Preparation method and application of immobilized cesium phosphotungstate catalyst

A cesium phosphotungstate catalyst technology, which is used in the preparation of medium and long-chain fatty acid glycerides, and in the field of preparation of solid-supported cesium phosphotungstate catalysts, can solve the problem of poor reusability and tediousness of free enzymes Separation and purification process, lipase is expensive and other problems, to achieve the effect of improving physical and chemical stability, wide application range, and conducive to adsorption and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

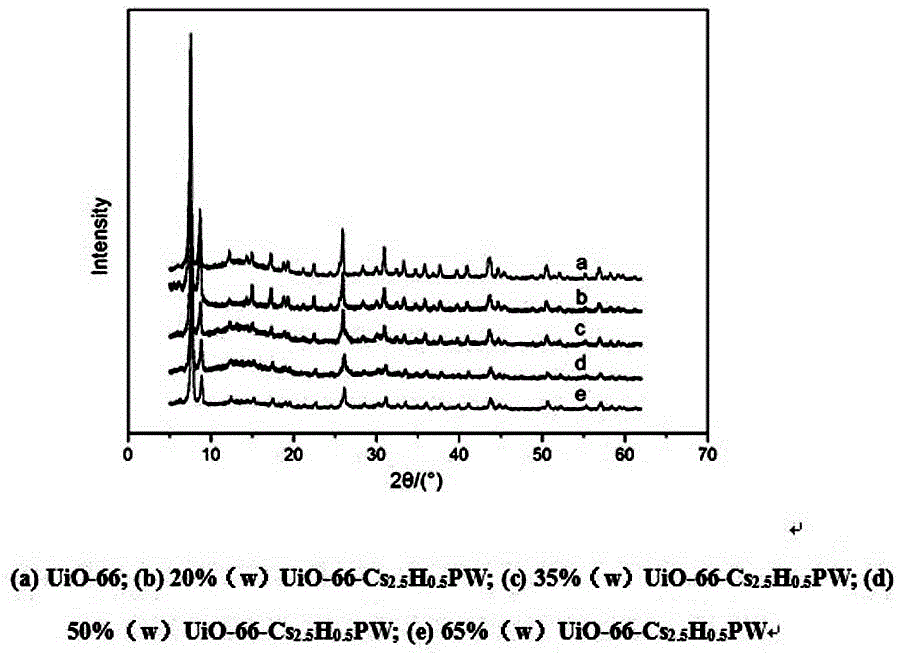

[0035] Immobilized cesium phosphotungstate catalyst of the present invention 20% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 The preparation method comprises the following steps:

[0036] The first step: active center Cs 2.5 h 0.5 PW 12 o 40 Preparation of:

[0037] Take 1.00 g cesium carbonate (Cs 2 CO 3 ) and 7.07 g phosphotungstic acid (H 3 PW 12 o 40 ) into 0.25 mol / L and 0.08 mol / L aqueous solutions, at room temperature, Cs 2 CO 3 The solution was added dropwise to H 3 PW 12 o 40 In the solution, the speed was kept at 1mL / min, and the magnetic force was strongly stirred for 8h, and the mixture was left to age for 12h, and then the mixture was slowly evaporated to dryness at 50°C; the obtained white solid was dried at 383 K for 12h, Calcined for 2 h to obtain cesium phosphotungstate (Cs 2.5 h 0.5 PW 12 o 40 )spare.

[0038] The second step: catalyst 20% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40Preparation of:

[0039] The reactor was placed in a 35°C water bath,...

Embodiment 2

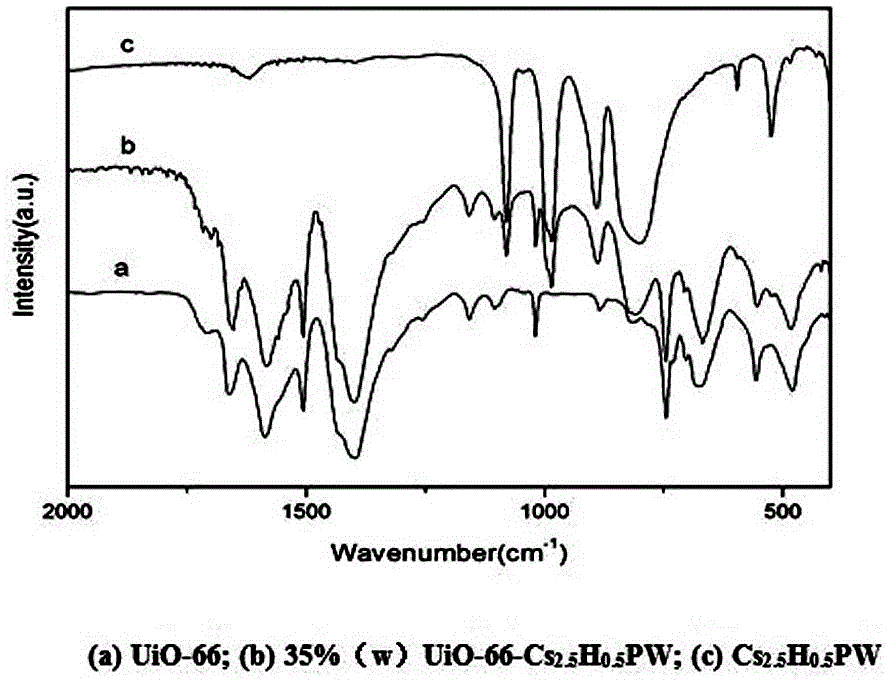

[0041] Immobilized cesium phosphotungstate catalyst of the present invention 35% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 The preparation method comprises the following steps:

[0042] The first step: with embodiment 1.

[0043] The second step: catalyst 35% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 Preparation of:

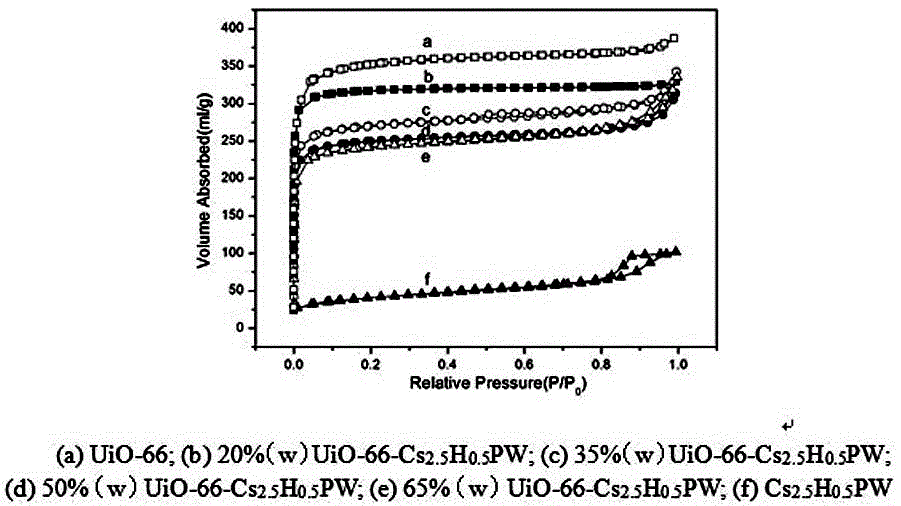

[0044] The reactor was placed in a 35°C water bath, 80mL DMF (N,N-dimethylformamide) was added to the reactor, and 2.0g of terephthalic acid H 2 (BDC) and 2.8g ZrCl 4 Dissolve in DMF, stir to dissolve, then add 1.5mL concentrated hydrochloric acid to it, stir for 3h, then add 1.05g cesium phosphotungstate salt, continue stirring for 2h, after mixing evenly, transfer the above reaction materials into a stainless steel reaction kettle, 120 Crystallize at ℃ for 30h, take out, filter, wash and dry. Before use, it was activated at a constant temperature of 180°C in an air atmosphere for 10 hours to obtain 35% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 Catalyst with a BET spe...

Embodiment 3

[0046] Immobilized cesium phosphotungstate catalyst of the present invention 50% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 The preparation method comprises the following steps:

[0047] The first step: with embodiment 1.

[0048] The second step: Catalyst 50% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 Preparation of:

[0049] The reactor was placed in a 35°C water bath, 80mL DMF (N,N-dimethylformamide) was added to the reactor, and 2.0g of terephthalic acid H 2 (BDC) and 2.8g ZrCl 4 Dissolve in DMF, stir to dissolve, then add 1.5mL concentrated hydrochloric acid to it, stir for 3h, then add 1.5g cesium phosphotungstic acid salt, continue stirring for 2h, after mixing evenly, transfer the above reaction materials into a stainless steel reaction kettle, 120 Crystallize at ℃ for 30h, take out, filter, wash and dry. Before use, it was activated at a constant temperature of 180°C in an air atmosphere for 10 hours to obtain 50% (w) UiO-66-Cs 2.5 h 0.5 PW 12 o 40 Catalyst with a BET ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com