Preparation method of high-penetration microporous granular active carbon

A granular activated carbon and microporous technology, which is applied in the field of waste recycling or reprocessing, can solve the problems affecting the improvement of the specific surface area of activated carbon, the tubular structure is easy to burst into pieces, and the activated micropores on the outer wall have poor penetrability, so as to enhance the adsorption capacity. , Improve the added value of product utilization, and reduce the effect of processing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

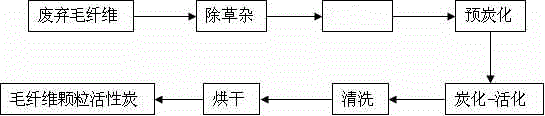

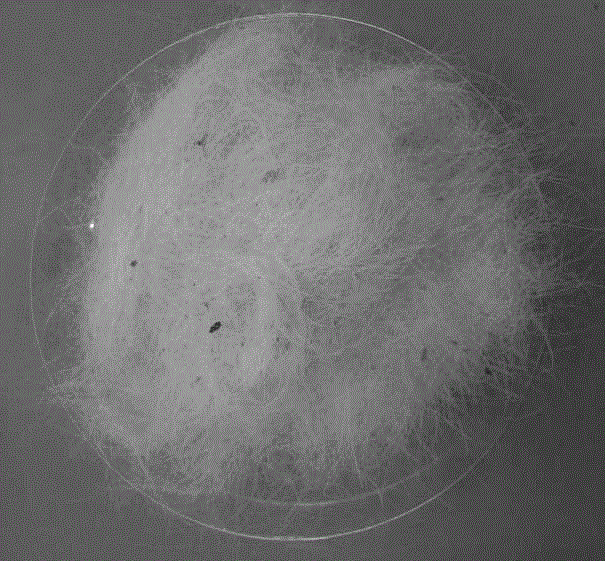

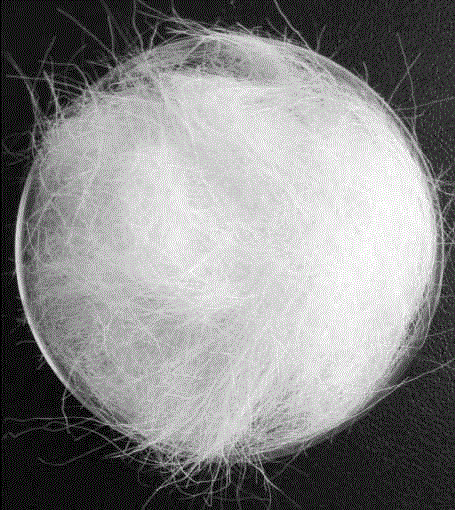

[0028] The processing technology of this embodiment can refer to figure 1 As shown, the waste cashmere needle wool fiber is treated with sulfuric acid in 3.0% sulfuric acid solution, baked and carbonized at 110°C after acid rolling, and then the plant weeds are removed by a charcoal crusher, then neutralized, and Teric N10 non-ionic washing is added (concentration 1.5%, bath ratio 1:35, temperature 50°C, washing times twice, the time distribution of the two washes is 10min, 5min) to remove fat and sweat from cashmere needle hair fibers, and finally wash with hot water at 40°C and dry , to obtain net cashmere needle wool fiber, compared figure 2 with image 3 It can be seen that the fiber wool color after purification treatment is bright and tidy, and the gloss is high; then, the clean cashmere needle hair fiber is cut into 15mm short hair with a rolling knife, and placed in a quartz tube muffle furnace under the protection of nitrogen. After 30 minutes of nitrogen gas, the ...

Embodiment 2

[0031] The processing technology of this embodiment can refer to figure 1As shown, put the waste cashmere needle wool fibers in 3.5% sulfuric acid solution for sulfuric acid treatment, after acid rolling, bake and carbonize at 105°C, then use a charcoal crusher to remove vegetable weeds, then neutralize, add Lissapol TN 450 non-ionic Detergent (concentration 1%, bath ratio 1:50, temperature 55°C, washing times twice, the time distribution of the two washes is 10min, 5min) to remove grease and sweat from cashmere needle hair fibers, and finally wash with hot water at 40°C and dry dry, to obtain net cashmere needle wool fibers, vs. figure 2 with image 3 It can be seen that the wool color of the purified fiber is bright and tidy, and the gloss is high; then, the clean cashmere needle hair fiber is cut into 10mm short hair with a rolling knife, and placed in a quartz tube muffle furnace under the protection of nitrogen. After nitrogen gas for 30 minutes, the temperature was ra...

Embodiment 3

[0034] The processing technology of this embodiment can refer to figure 1 As shown, put the waste cashmere needle wool fibers in 3.5% sulfuric acid solution for sulfuric acid treatment, after acid rolling, bake and carbonize at 105°C, then use a charcoal crusher to remove vegetable weeds, then neutralize, add Lissapol TN 450 non-ionic Detergent (concentration 1%, bath ratio 1:50, temperature 55°C, washing times twice, the time distribution of the two washes is 10min, 5min) to remove grease and sweat from cashmere needle hair fibers, and finally wash with hot water at 40°C and dry dry, to obtain waste net wool fiber, contrast figure 2 with image 3 It can be seen that the wool color of the purified fiber is bright and tidy, and the gloss is high; then, the clean cashmere needle hair fiber is cut into 5 mm short hairs with a rolling knife, and placed in a quartz tube muffle furnace under the protection of nitrogen. After 30 minutes of nitrogen gas, the temperature was raised ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com