Method for preparing nanometer molybdenum disulfide powder

A nano-molybdenum disulfide and powder technology, applied in the direction of molybdenum sulfide, etc., can solve the problems that it is difficult to obtain a product with uniform composition, cannot obtain a two-dimensional lamellar structure, and the grain size distribution is uneven, and the grain size can be reached. Uniform and controllable, low cost, and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

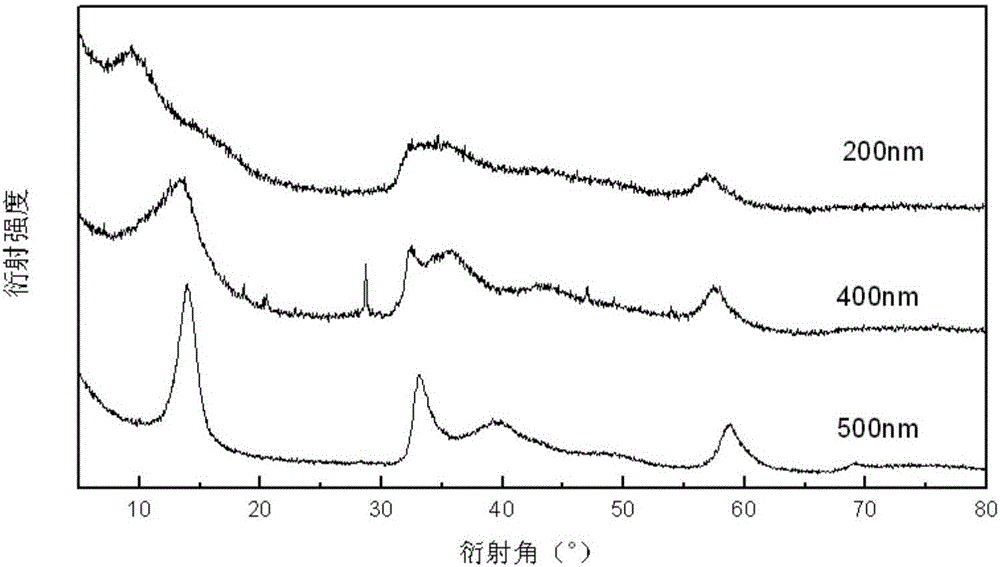

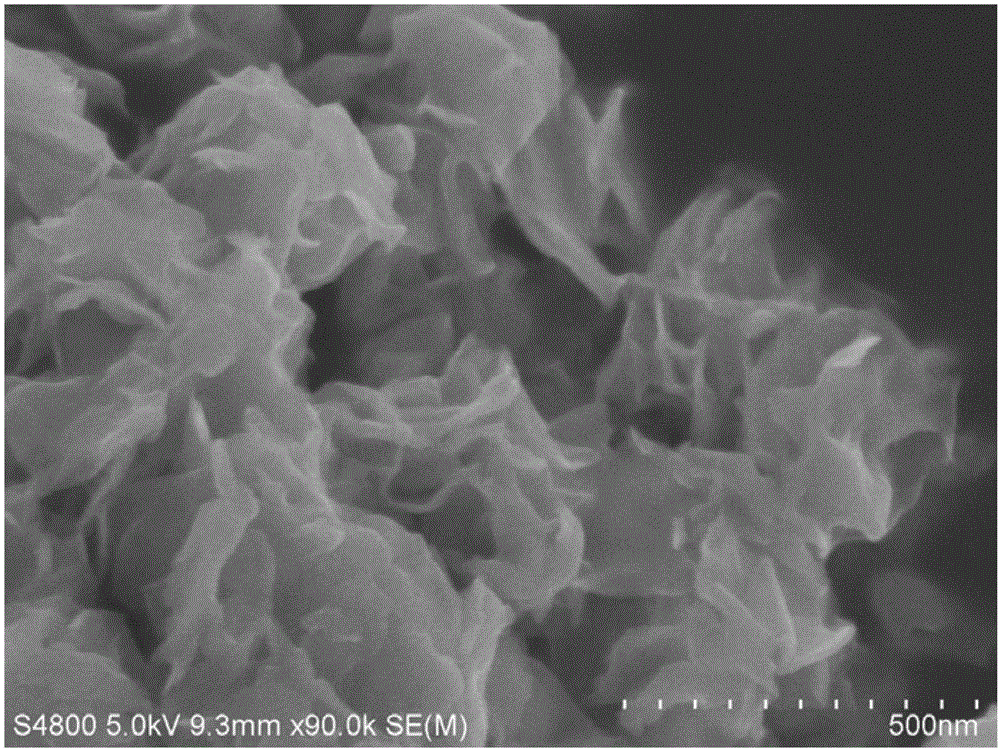

[0035] Add 10mmol ammonium molybdate and 20mmol thiourea to the beaker, add 100ml of deionized water to the beaker, stir for 1 hour to fully dissolve the ammonium molybdate and thiourea, and transfer the solution into a 150ml polythene In the reaction kettle lined with tetrafluoroethylene, seal it; place the reaction kettle in an electric oven, set the oven temperature to 220°C, and set the reaction time to 24 hours; when the reaction time is up, take out the reaction kettle and put the inside The mixture in the lining is suction filtered and dried; the dried solid is placed in a beaker, and an aqueous solution with a volume fraction of isopropanol of 30% is added. After ultrasonic stripping for 5 hours, the dispersion is transferred to a centrifuge tube, and the centrifugal speed is 5000r / min Centrifuge down, retain the supernatant and collect the solid therein, and the obtained product is nanometer molybdenum disulfide powder with a particle size of about 500nm. Such as fig...

Embodiment 2

[0037] Add 10mmol ammonium molybdate and 20mmol thiourea to the beaker, add 100ml of deionized water to the beaker, stir for 1 hour to fully dissolve the ammonium molybdate and thiourea, and transfer the solution into a 150ml polythene In the reaction kettle lined with tetrafluoroethylene, it is sealed; the reaction kettle is placed in an electric oven, the oven temperature is set to 220 ° C, and the reaction time is set to 18 hours; when the reaction time is up, the reaction kettle is taken out, and the inner The mixture in the lining is suction filtered and dried; the dried solid is placed in a beaker, and an aqueous solution with a volume fraction of isopropanol of 50% is added, and after ultrasonic stripping for 5 hours, the dispersion is transferred to a centrifuge tube, at a centrifugal speed of 7000r / min Centrifuge down, retain the supernatant and collect the solid therein, and the obtained product is nanometer molybdenum disulfide powder with a particle size of about 40...

Embodiment 3

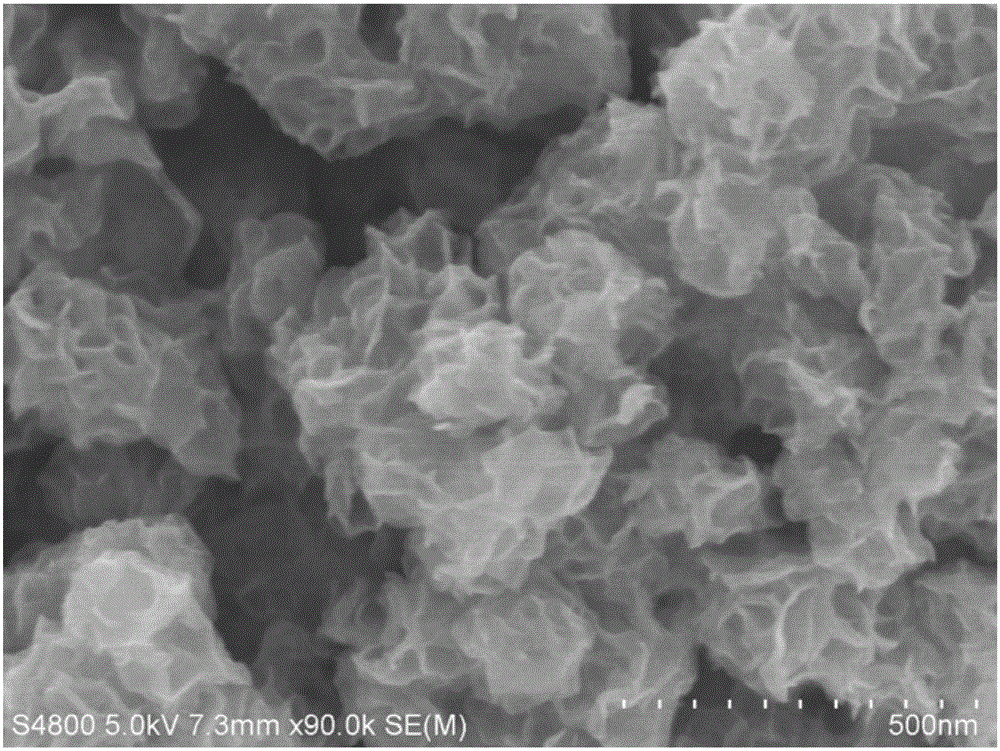

[0039] Add 10mmol ammonium molybdate and 20mmol thiourea to the beaker, add 100ml of deionized water to the beaker, stir for 1 hour to fully dissolve the ammonium molybdate and thiourea, and transfer the solution into a 150ml polythene In the reaction kettle lined with tetrafluoroethylene, seal it; place the reaction kettle in an electric oven, set the oven temperature to 240°C, and set the reaction time to 9 hours; when the reaction time is up, take out the reaction kettle and put the inside The mixture in the lining is suction filtered and dried; the dried solid is placed in a beaker, and an aqueous solution with a volume fraction of isopropanol of 60% is added, and after ultrasonic peeling for 8 hours, the dispersion is transferred to a centrifuge tube, and the centrifugal speed is 12000r / min centrifuge, retain the supernatant and collect the solid therein, and the obtained product is nanometer molybdenum disulfide powder with a particle size of 200nm. from figure 1 It can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com