Creep-resistant antistatic palm fiber-reinforced polyethylene composite material and preparation method thereof

A technology of palm fiber and composite materials, which is applied in the field of composite materials, can solve the problems of poor corrosion resistance, heavy steel pipe weight, non-corrosion-resistant toughness, etc., to solve the problem of insufficient creep resistance, improve creep resistance, and improve the resistance to corrosion. The effect of electrostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

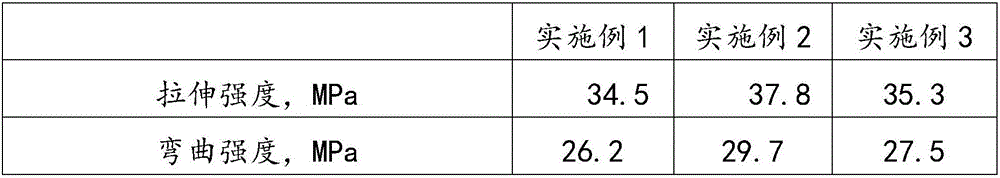

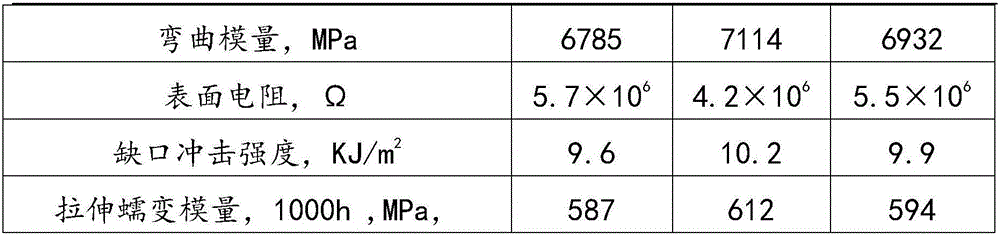

Embodiment 1

[0015] An anti-creep and anti-static palm fiber reinforced polyethylene composite material is prepared from the following raw materials in parts by weight (kg): polyethylene 130, perfluoroethylene propylene copolymer 20, polyethersulfone 10, fumaric acid rosin pentaerythritol Ester 6, tetraethylene glycol diheptanoate 5, dicyclohexyl peroxycarbonate 3, ethoxyaminopropyl polydimethylsiloxane 7, bis(3,5-di-tert-butyl-4- Hydroxybenzyl) sulfide 5, octyl salicylate 6, aluminum distearate 4, liquid paraffin 4, stearamidopropylamine oxide 3, tin methyl mercaptide 3, cyclohexane-1,2-di Diisooctyl formate 8, palm fiber 14, nano silicon dioxide 8, conductive mica powder 10, calcined clay 7, basic magnesium chloride whisker 7, asbestos powder 4.

[0016] A preparation method for anti-creep and anti-static palm fiber reinforced polyethylene composite material, comprising the following steps:

[0017] (1) Dry polyethylene and perfluoroethylene propylene copolymer at a temperature of 110-1...

Embodiment 2

[0022] An anti-creep and anti-static palm fiber reinforced polyethylene composite material is prepared from the following raw materials in parts by weight (kg): polyethylene 135, perfluoroethylene propylene copolymer 25, polyethersulfone 12.5, fumaric acid rosin pentaerythritol Ester 7, tetraethylene glycol diheptanoate 6, dicyclohexyl peroxycarbonate 4, ethoxyaminopropyl polydimethylsiloxane 8, bis(3,5-di-tert-butyl-4- Hydroxybenzyl) sulfide 6, octyl salicylate 7.5, aluminum distearate 5, liquid paraffin 4.5, octadecylamidopropylamine oxide 4, methyl mercaptide 4, cyclohexane-1,2-di Diisooctyl formate 8.5, palm fiber 15, nano silicon dioxide 9, conductive mica powder 11, calcined clay 8, carbonization 8, asbestos 5.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] An anti-creep and anti-static palm fiber reinforced polyethylene composite material, which is prepared from the following raw materials in parts by weight (kg): polyethylene 140, perfluoroethylene propylene copolymer 30, polyethersulfone 15, fumaric acid rosin pentaerythritol Ester 8, tetraethylene glycol diheptanoate 7, dicyclohexyl peroxycarbonate 5, ethoxyaminopropyl polydimethylsiloxane 9, bis(3,5-di-tert-butyl-4- Hydroxybenzyl) sulfide 7, octyl salicylate 9, aluminum distearate 6, liquid paraffin 5, octadecylamidopropylamine oxide 5, tin methyl mercaptide 5, cyclohexane-1,2-di Diisooctyl formate 9, palm fiber 16, nano silicon dioxide 10, conductive mica powder 12, calcined clay 9, basic magnesium chloride whisker 9, asbestos powder 6.

[0026] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com