High-inflaming-retarding and low-heating-value smoke-eliminating halogen-free B1-grade aluminum-plastic compounding panel core material and preparing method thereof

A technology of aluminum-plastic composite board and low calorific value, which is applied in the field of flame-retardant plastic building materials, can solve the problems of invisibility, etc., and achieve the effect of high polarity, high peel strength and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: High Flame Retardancy, Low Calorific Value, Smoke Suppression and Halogen Free B 1 Preparation of core material for aluminum-plastic composite board

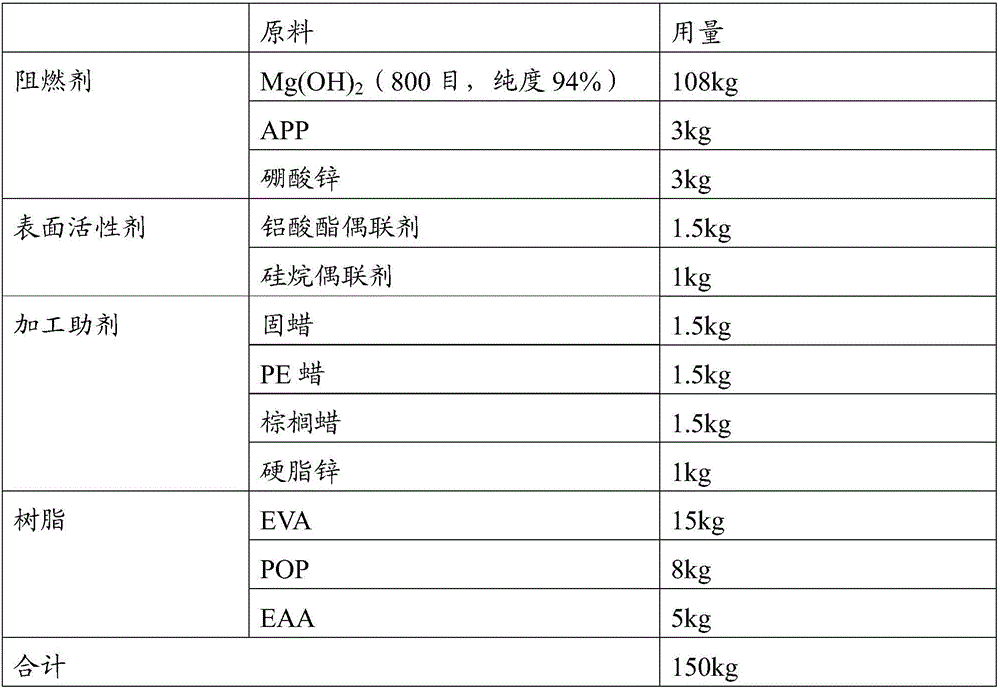

[0035] 1. Ingredients list

[0036] Table 1

[0037]

[0038] 2. Method

[0039] 108kg 800 mesh Mg(OH) 2 (purity 94%), 3kg APP, 3kg zinc borate, 1.5kg aluminate coupling agent, and 1kg silane coupling agent are added together in a 300L high-speed mixer and stirred at a high speed until the temperature rises to 105°C before adding 1.5kg of solid wax. 1.5kg PE wax, 1.5kg palm wax, 1kg zinc stearate, 15kg EVA, 8kg POP and 5kg EAA, continue to stir at high speed until the temperature reaches 120°C and then discharge.

[0040] When the above-mentioned treated materials are cooled to 40°C, they are then extruded and granulated with a parallel twin-screw extruder at 135-150°C to obtain 150kg of qualified products.

Embodiment 2

[0041] Example 2: High Flame Retardancy, Low Calorific Value, Smoke Suppression and Halogen Free B 1 Preparation of core material for aluminum-plastic composite board

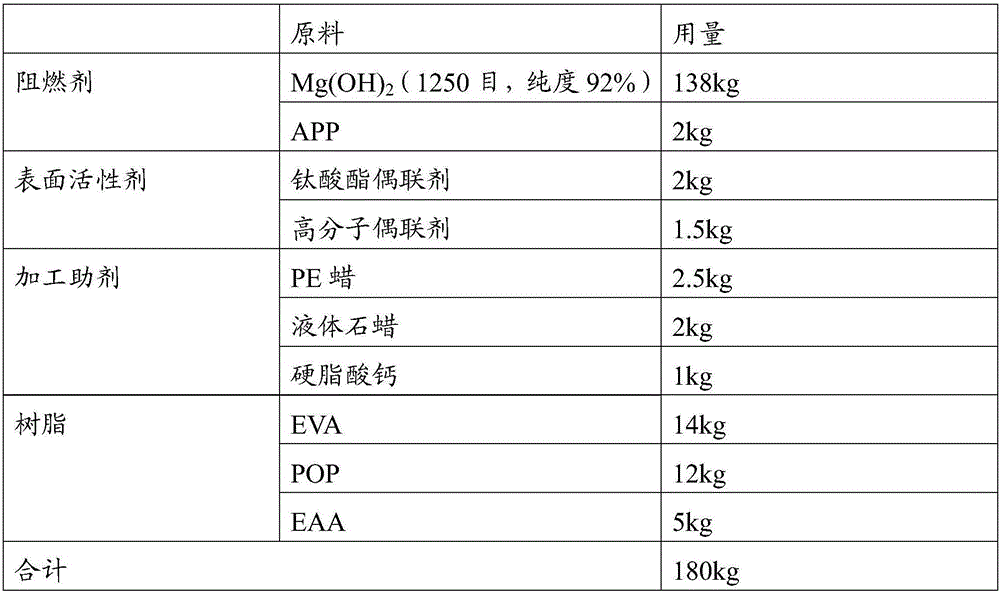

[0042] 1. Ingredients list

[0043] Table 2

[0044]

[0045] 2. Method

[0046] 138kg 1250 mesh Mg(OH) 2 (purity 92%), 2kg APP, 2kg titanate coupling agent, 1.5kg polymer coupling agent, 2.5kg PE wax, 2kg liquid paraffin, 1kg calcium stearate, 14kg EVA, 12kg POP and 5kg EAA In a 110L internal mixer, masticate for 12 minutes. When the temperature rises to 140°C and the material melts into a dough, it can be discharged, and then the dough-like material is transferred to the conical single-screw extruder while it is hot, and the Extrude and granulate at ~150°C to produce 180kg of qualified products.

Embodiment 3

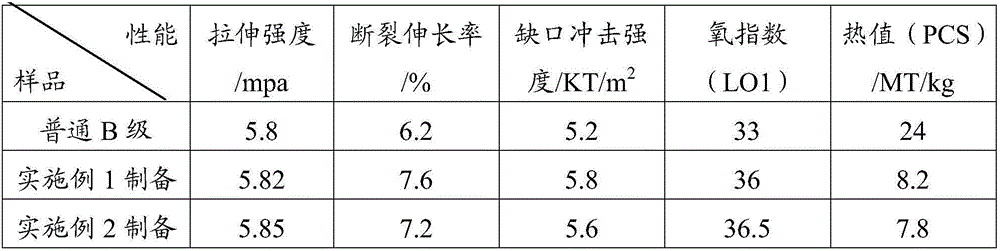

[0047] Embodiment 3 comparative test

[0048] Two kinds of high flame retardant low calorific value smoke-eliminating and halogen-free B prepared in Example 1 and Example 3 1 The performance test of the core material of the grade B aluminum-plastic composite panel was carried out, and the performance of the core material of the ordinary B-grade aluminum-plastic composite panel was compared. The results are shown in Table 3 below.

[0049] Table 3 Invention B 1 Performance comparison between grade B aluminum-plastic composite panel core material and ordinary B-grade aluminum-plastic composite panel core material

[0050]

[0051] It can be seen from the results in Table 3 that compared with the common B-grade aluminum-plastic composite board core material, the high flame-retardant low-calorific value smoke-elimination and halogen-free B 1 The high-grade aluminum-plastic composite board core material has a high oxygen index and low calorific value, indicating that the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com