Corona-inhibiting and three-proofing insulating paint for large generators and preparation method of corona-inhibiting and three-proofing insulating paint

A technology for insulating coatings and generators, used in anti-corrosion coatings, organic insulators, anti-fouling/underwater coatings, etc., which can solve the adverse effects of insulation, corona suppression and "three-proof" performance, complex and changeable substrates , reduce equipment reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

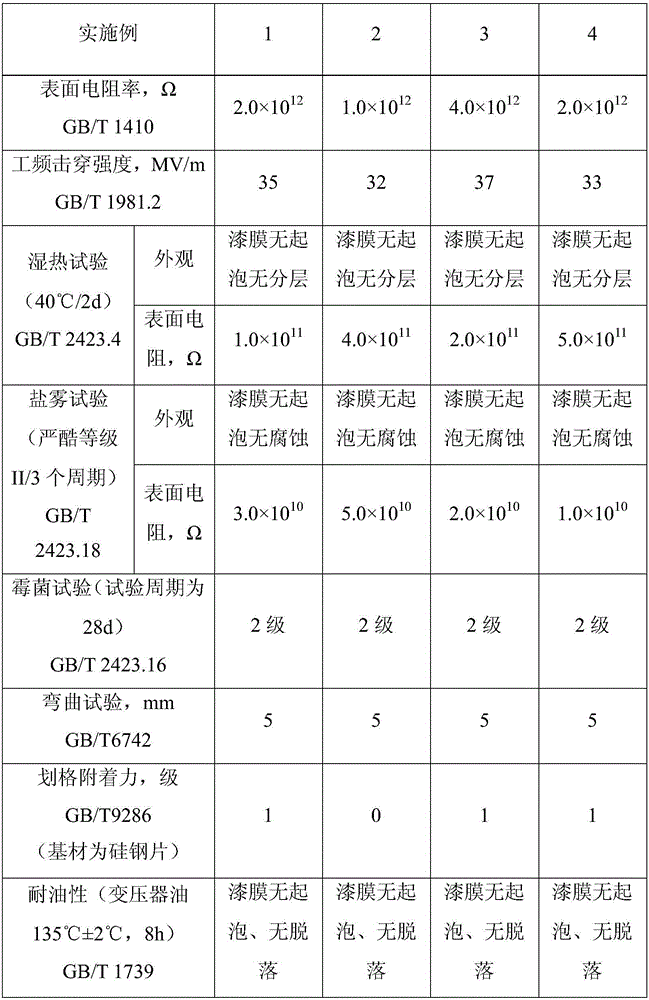

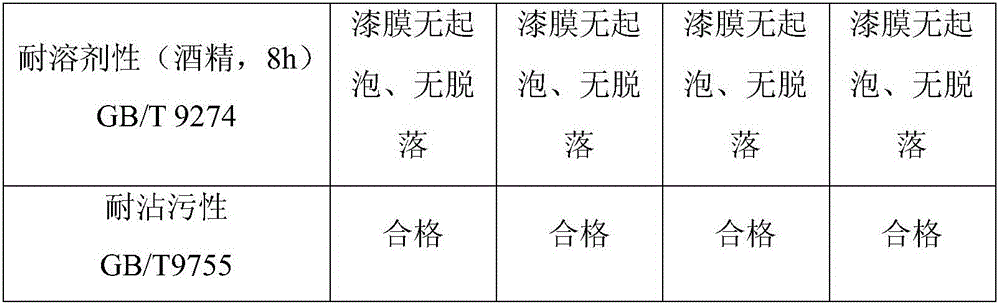

Examples

Embodiment 1

[0027] Component A: Add 2 parts by weight of aminomethylmethoxysilane to 8 parts by weight of n-butanol, raise the temperature to 65°C, and add 9 parts by weight of nano-SiO 2 Particles, stirred for 0.5h under heat preservation; then added 1 part by weight of polymethylnonafluorohexylsiloxane with a viscosity of 2.5mPas, heated to 80°C, stirred for 1.5h under heat preservation, and then mixed with the above Add 4 parts by weight of bisphenol A epoxy resin (epoxy value 0.5eq / 100g), 2 parts by weight of bisphenol F epoxy resin (0.42eq / 100g epoxy value), 6 parts by weight of CTBN toughening Modified epoxy resin, 2.5 parts by weight of nano zinc oxide, 7 parts by weight of micaceous iron oxide, 2 parts by weight of silicon carbide, 0.4 parts by weight of carbon black, 10 parts by weight of iron oxide red, 5 parts by weight of iron oxide Black, 5 parts by weight of aluminum polyphosphate, 3 parts by weight of barium sulfate, 1.5 parts by weight of a compound broad-spectrum anti-mil...

Embodiment 2

[0030] Component A: Add 1.5 parts by weight of aminoethylaminopropyltrimethoxysilane to 8 parts by weight of cyclohexanone, heat up to 58°C, and add 8 parts by weight of nano-SiO 2 Particles, stirred for 0.5h under heat preservation; then added 1.5 parts by weight of polyheptadecafluorodecylmethylsiloxane with a viscosity of 7mPas, heated to 76°C, stirred for 1.5h under heat preservation, and then added to the above-mentioned Add 3 parts by weight of bisphenol A epoxy resin (epoxy value 0.45eq / 100g), 4 parts by weight of bisphenol F epoxy resin (0.45eq / 100g of epoxy value), 7 parts by weight of CTBN epoxy resin in the mixing system Tough modified epoxy resin, 4 parts by weight of nano-zinc oxide, 6 parts by weight of micaceous iron oxide, 2 parts by weight of silicon carbide, 0.4 parts by weight of carbon black, 10 parts by weight of iron oxide red, 3 parts by weight of oxide Iron black, 5 parts by weight of aluminum polyphosphate, 3 parts by weight of barium sulfate, 1.5 part...

Embodiment 3

[0033] Component A: Add 1.2 parts by weight of aminomethyltrimethoxysilane to 7 parts by weight of xylene, heat up to 60°C, add 8 parts by weight of nano-SiO 2 Particles, stirred for 0.5h under heat preservation; then added 1.8 parts by weight of polymethyltrifluoropropylsiloxane with a viscosity of 14mPas, heated to 82°C, stirred for 1.5h under heat preservation, and then mixed with the above Add 4 parts by weight of bisphenol A epoxy resin (epoxy value 0.52eq / 100g), 2 parts by weight of bisphenol F epoxy resin (0.36eq / 100g of epoxy value), 6 parts by weight of CTBN toughening Modified epoxy resin, 2.5 parts by weight of nano-zinc oxide, 6 parts by weight of micaceous iron oxide, 2 parts by weight of silicon carbide, 0.5 parts by weight of carbon black, 12 parts by weight of iron oxide red, 3 parts by weight of iron oxide black, 5 parts by weight of aluminum polyphosphate, 4 parts by weight of barium sulfate, 1.2 parts by weight of compound broad-spectrum anti-mildew and anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com