A kind of water-based environment-friendly high-temperature paint and preparation method thereof

A water-based and coating technology, applied in the direction of coating, etc., can solve the problems of reduced equipment life, increased production costs, and hidden dangers in production safety, and achieve the effects of high decoration, durable coating, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

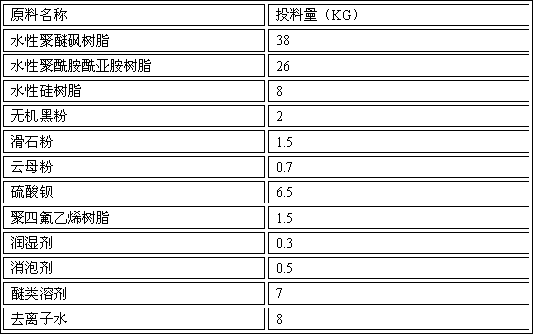

[0040] The components and proportions of the water-based environmentally friendly high-temperature paint in this embodiment are shown in Table 1, wherein the pigment is black powder, which is a common product sold in the market. Add 38KG of water-based polyethersulfone resin, 26KG of water-based polyamideimide resin, 8KG of water-based silicone resin and 2KG of inorganic black powder into the grinding kettle, and grind at a high speed of 1900-2000rpm for 2 hours to make the material fine 1.5KG of polytetrafluoroethylene resin, 1.5KG of talc powder, 0.7KG of mica powder and 6.5KG of barium sulfate were ground in a grinding kettle to below 5 μm to form mixture 2; In a stirred tank, mix 7KG of ether solvent and 8KG of deionized water evenly and then add to the mixture 2 for stirring, so that the materials are mixed evenly to form a mixture 3; Stir KG of defoamer and 0.3KG of wetting agent to mix the materials evenly.

[0041] Table 1 Embodiment 1 component and consumption table ...

Embodiment 2

[0047]The components and proportions of the water-based environment-friendly high-temperature paint in this embodiment are shown in Table 3, wherein the pigments are black powder and silver powder, which are common products sold in the market. Add 18KG of water-based polyethersulfone resin, 36KG of water-based polyamideimide resin, 12KG of water-based silicone resin, 3KG of black powder and 1.5KG of silver powder into the grinding kettle, and grind at a high speed of 1900-2000rpm for 2 hours , so that the fineness of the material reaches below 5 μm to form a mixture 4; 3.55KG of polytetrafluoroethylene resin, 3.5KG of talcum powder and 2.7KG of mica powder are ground in a grinding kettle to below 5 μm respectively to form a mixture 5; In the still, mix 7KG of ether solvent and 18KG of deionized water evenly, then add it to the mixture 5 and stir, so that the materials are mixed evenly to form the mixture 6; Stir the defoamer and 0.3KG wetting agent to make the material mix eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com