Protective film easy to recycle

A technology of protective film and polypropylene film, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, adhesive additive, etc., which can solve the problems of difficult handling, peeling off of substrate layer, and easy damping of adhesive layer. , to achieve the effect of reducing pollution, improving adhesion, and superior moisture and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

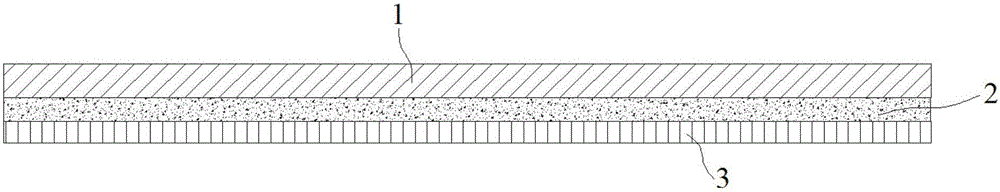

[0036] Embodiment 1~4: A kind of protective film that is convenient for recycling, comprises polypropylene film 1, pressure-sensitive modified EVA adhesive layer 2 and release material layer 3, and described pressure-sensitive modified EVA adhesive layer 2 Located between the polypropylene film 1 and the release material layer 3;

[0037] The pressure-sensitive modified EVA adhesive layer 2 is composed of the following components in parts by weight:

[0038] Table 1

[0039]

[0040] The modified EVA aqueous solution includes the following components by weight, as shown in Table 2, and also includes deionized water as a solvent:

[0041]

[0042] The modified EVA aqueous solution is further obtained through the following steps:

[0043] Step 1, dissolving 20-40 parts of polyvinyl alcohol, 6-8 parts of sodium isooctanoate, 2-4 parts of potassium sulfite and 0.05-0.1 part of ferrous sulfate in ionized water to form an aqueous mixture;

[0044] Step 2, put the aqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com