A method for preparing ceramic film/glaze film composite coating on titanium alloy surface

A technology of ceramic coating and titanium alloy, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., to achieve the effects of good film-base bonding force, simple operation, and improved wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Pretreatment of titanium alloy samples

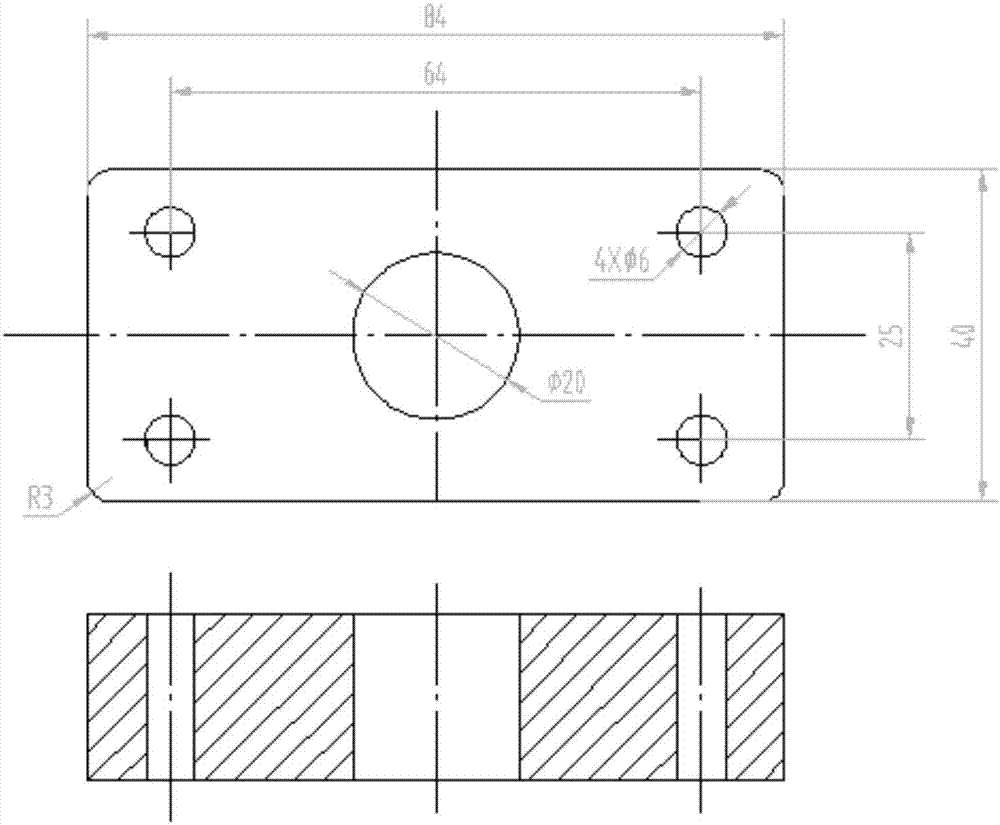

[0029] The titanium alloy TC4 sample is processed into such as figure 1 As shown, the thickness is 20mm. Grind the processed samples with 180#, 400#, 600#, 800#, 1200#, 1500#, 2000# sandpaper until the surface is smooth. Then use a polishing machine, a polishing cloth and a 1 μm alumina polishing paste to polish the titanium alloy sample to a mirror surface appearance of Ra≈0.3 μm.

[0030] 2. Preparation of micro-arc oxidation coating

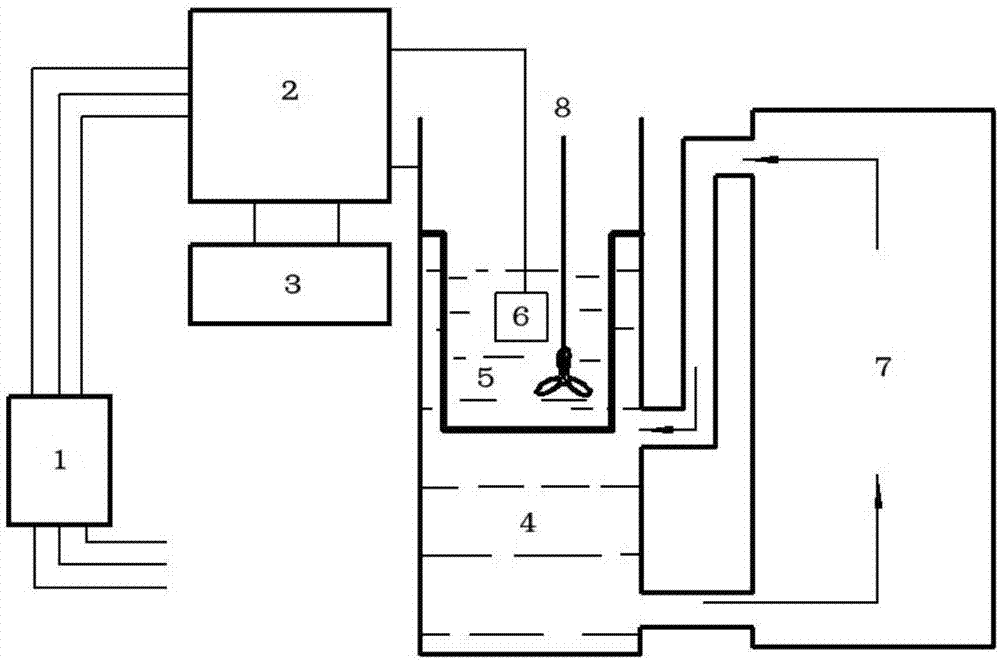

[0031] Rinse the polished titanium alloy samples with clean water respectively, and then place the samples in an acetone solution for ultrasonic cleaning for 10 minutes to remove oil. The cleaning frequency is 100,000HZ. Rinse with deionized water after ultrasonic cleaning, take out and blow dry. Then install the sample in the micro-arc oxidation equipment (such as figure 2 As shown), the electrolyte composition and micro-arc oxidation parameters are shown in Table 1.

[0032] Table 1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com