A kind of moon coating and its preparation method and application

A coating and substrate technology, applied in the field of thin film electrode and surface protective coating preparation, can solve the problems such as affecting the electrochemical electrode energy storage performance of the electrode, difficult to flexible electrodes and flexible energy storage devices, reducing the effective specific surface area of the electrode, etc. , to achieve the effect of improving the interface electrical contact, good film-base adhesion, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

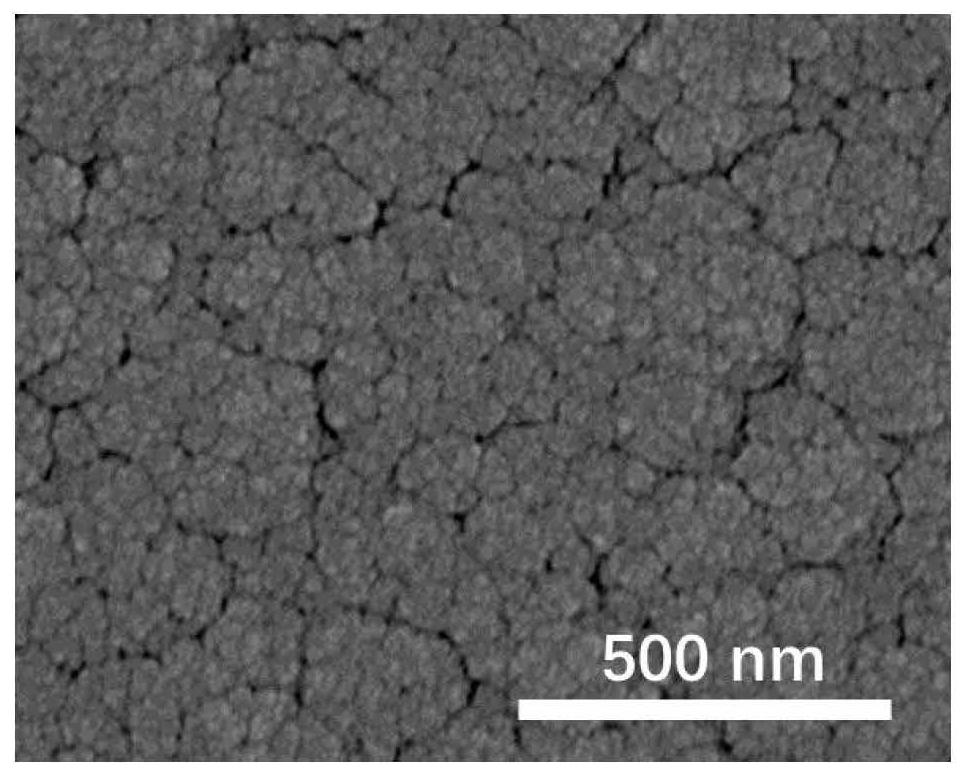

Embodiment 1

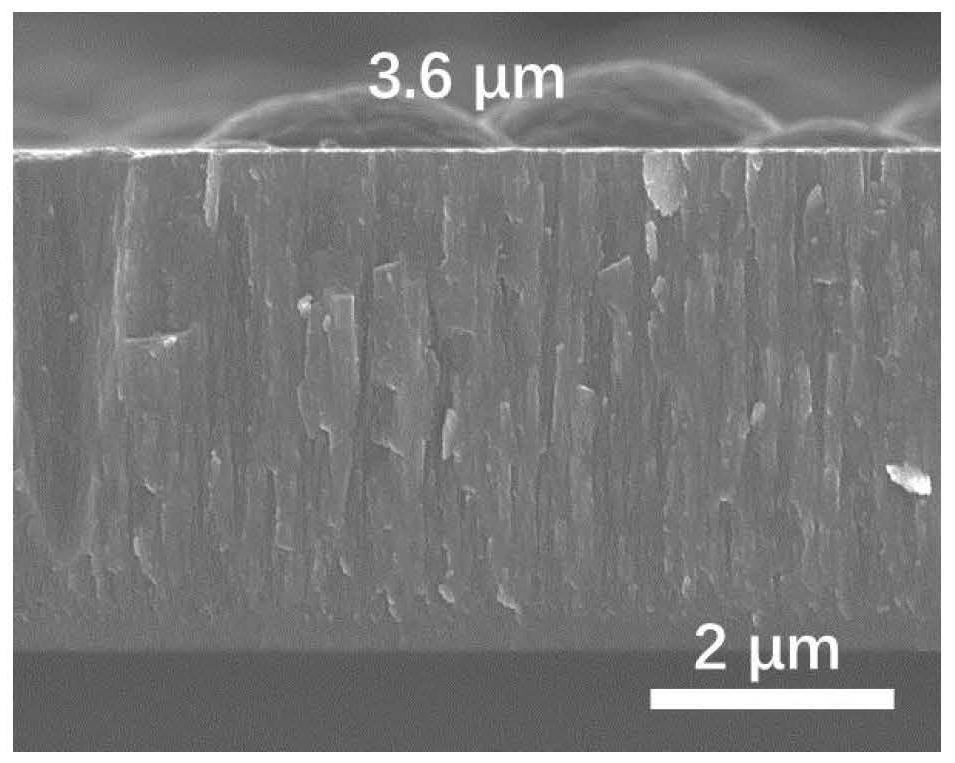

[0037] 1. Fix the pretreated P-doped conductive silicon or flexible graphite film substrate on the workpiece turret in the coating chamber, so that the substrate is facing the surface of the molybdenum target, the distance between the target and the base is 26cm, and the rotation speed of the turret is adjusted to 10rpm. The speed is 0rpm, turn on the heater to raise the temperature to 300°C, and pre-pump the background vacuum to 5.0×10 -3 Pa;

[0038] 2. Open the Ar gas flow valve, adjust the air pressure to 0.5Pa, turn on the DC pulse bias power supply, adjust the substrate bias voltage to -600V, duty cycle 30%, frequency 40kHz, open the anode layer ion source and adjust the current 5A to conduct Ion source etching and cleaning for 5 minutes;

[0039] 3. Reduce the substrate bias to -150V, turn on Ar, N 2 Gas flow valve, adjust Ar / N 2 The flow ratio is 1:4, adjust the total air pressure to 0.9Pa, turn on the Cr arc target, adjust the target current to 80A, and deposit for...

Embodiment 2

[0049] 1. Fix the pretreated P-doped conductive silicon or flexible graphite film substrate on the workpiece turret in the coating chamber, so that the substrate is facing the surface of the molybdenum target, the distance between the target and the base is 26cm, and the rotation speed of the turret is adjusted to 10rpm. The speed is 0rpm, turn on the heater to raise the temperature to 300°C, and pre-pump the background vacuum to 5.0×10 -3 Pa;

[0050] 2. Open the Ar gas flow valve, adjust the air pressure to 0.5Pa, turn on the DC pulse bias power supply, adjust the substrate bias voltage to -600V, duty cycle 30%, frequency 40kHz, open the anode layer ion source and adjust the current 5A to conduct Ion source etching and cleaning for 5 minutes;

[0051] 3. Reduce the substrate bias to -150V, turn on Ar, N 2 Gas flow valve, adjust Ar / N 2 The flow ratio is 1:4, adjust the total air pressure to 0.9Pa, turn on the Cr arc target, adjust the target current to 80A, and deposit for...

Embodiment 3

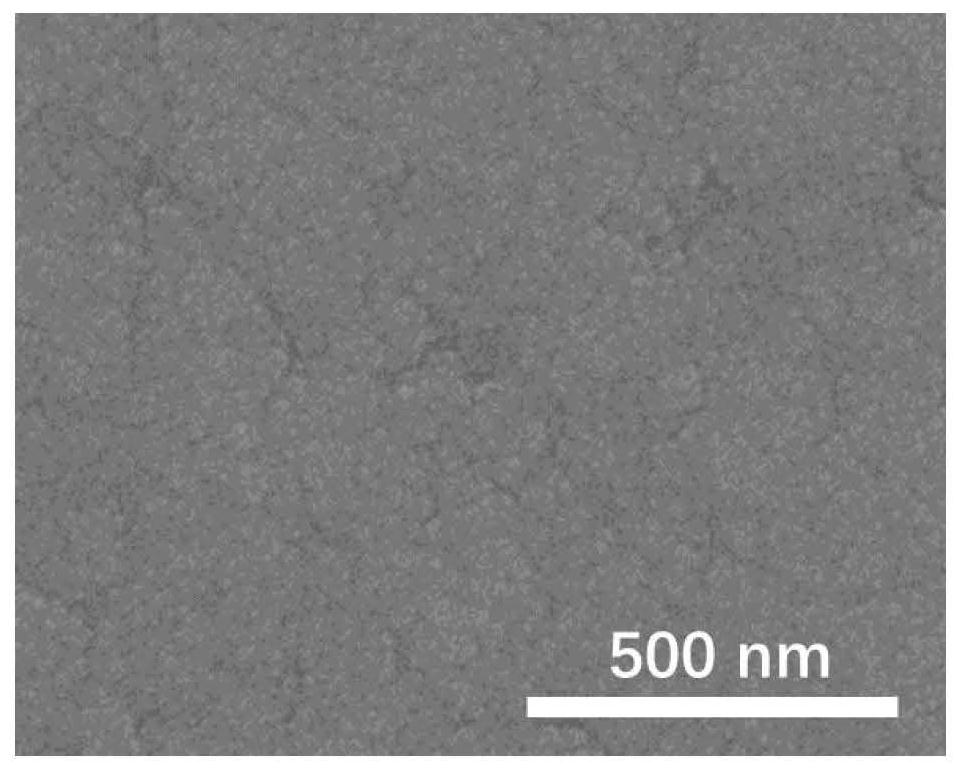

[0055] The MoON coating was prepared by the pulsed magnetron sputtering deposition method in Example 1, and the atomic percentage content of each element in the layer was: Mo: 26 at.%, O: 40 at.%, N: 34 at.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com