Method for depositing protection film on the ceramics valve core surface

A technology of ceramic valve core and protective film, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of large valve core wear, easy peeling, poor bonding force, etc., and achieve improved wear-resistant sealing Performance and service life, good binding force of film base, and effect of improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

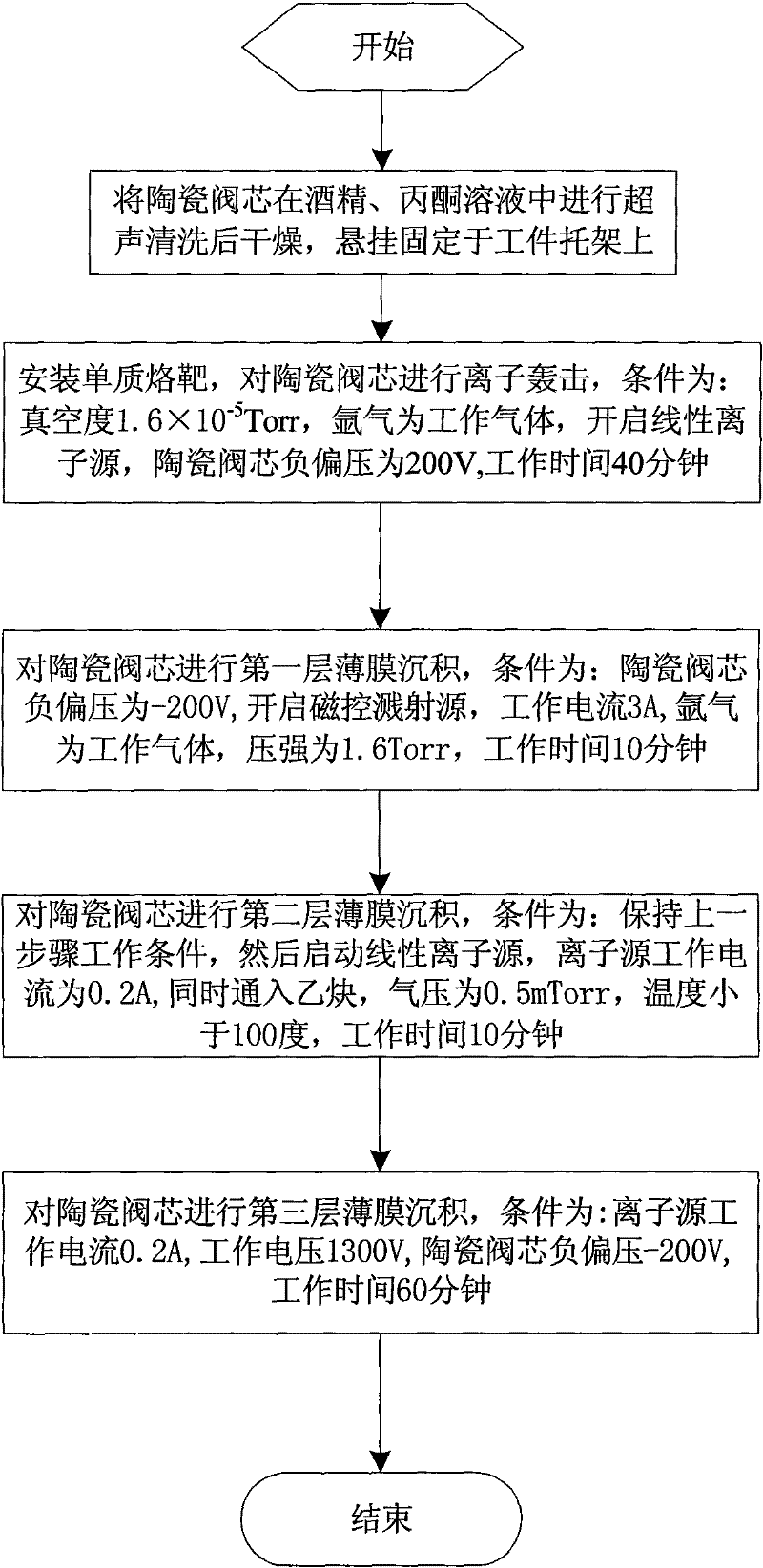

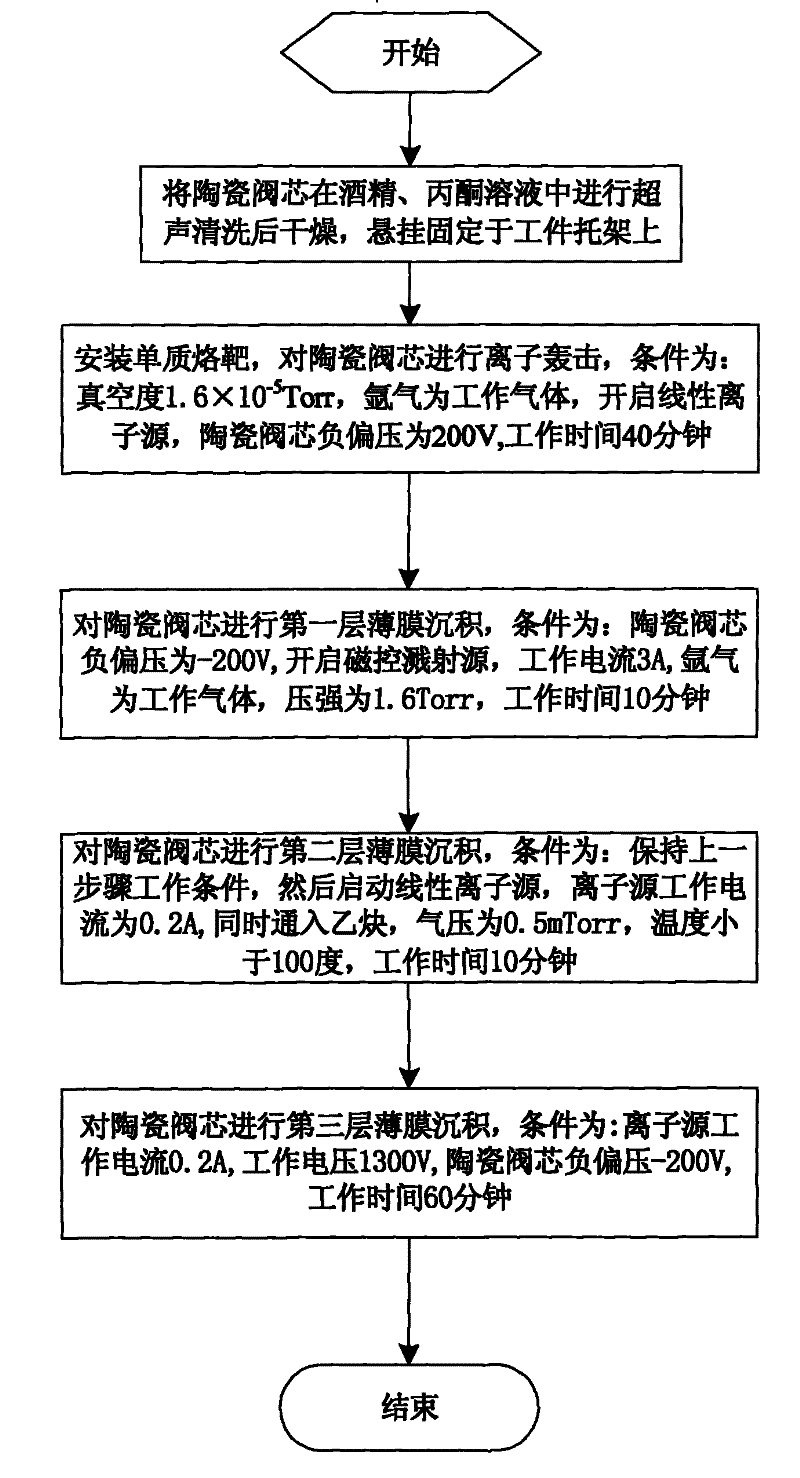

[0023] The invention provides a method for depositing a protective film on the surface of a ceramic valve core. The coating machine used includes a vacuum chamber, a magnetron sputtering source, a linear ion source and a workpiece bracket with both revolution and rotation. The workpiece bracket is installed Inside the vacuum chamber, it includes the following steps: see figure 1 shown

[0024] (1) Ultrasonic cleaning of the ceramic valve core in acetone solution, then ultrasonic cleaning in alcohol solution, after drying, hanging and fixing on the workpiece bracket, so that the magnetron sputtering source and linear ion source surround the ceramic Around the spool;

[0025] (2) Install a simple chromium target on the magnetron sputtering source, and evacuate the vacuum chamber to 1.6×10 -5 After Torr, argon gas is introduced, the linear ion source is turned on, the negative bias voltage of the ceramic valve core is adjusted to 200V, and the ceramic valve core is subjected to...

Embodiment 2

[0031] The difference from the first embodiment is that in step (2), the magnetron sputtering source is installed with a simple titanium target.

Embodiment 3

[0033] The difference from the first embodiment is that in step (2), the magnetron sputtering source is installed with a simple tungsten target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com