High-capacity graphene-based supercapacitor electrode material and preparation method thereof

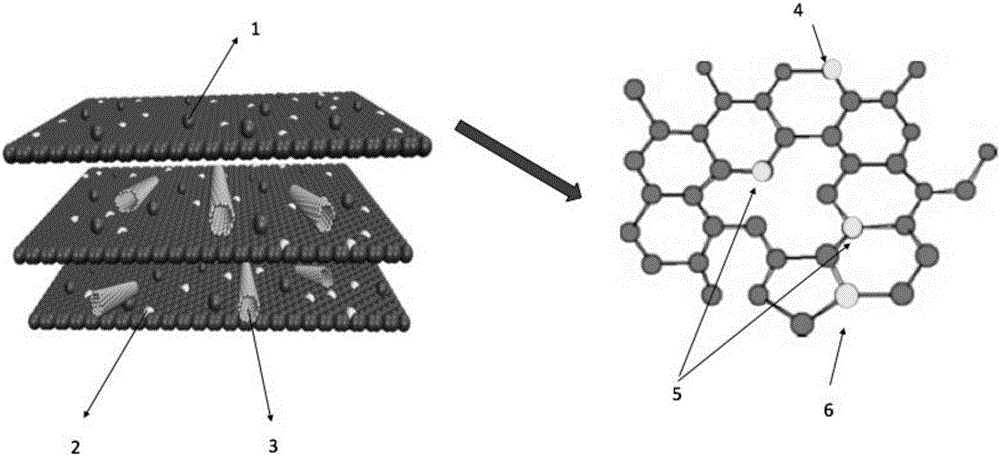

A supercapacitor, graphene-based technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve problems such as hindering electrolyte ions, reducing electrostatic repulsion between graphene sheets, and low specific capacity, and achieves suppression of The effect of agglomeration, increasing surface reactive sites, and improving chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

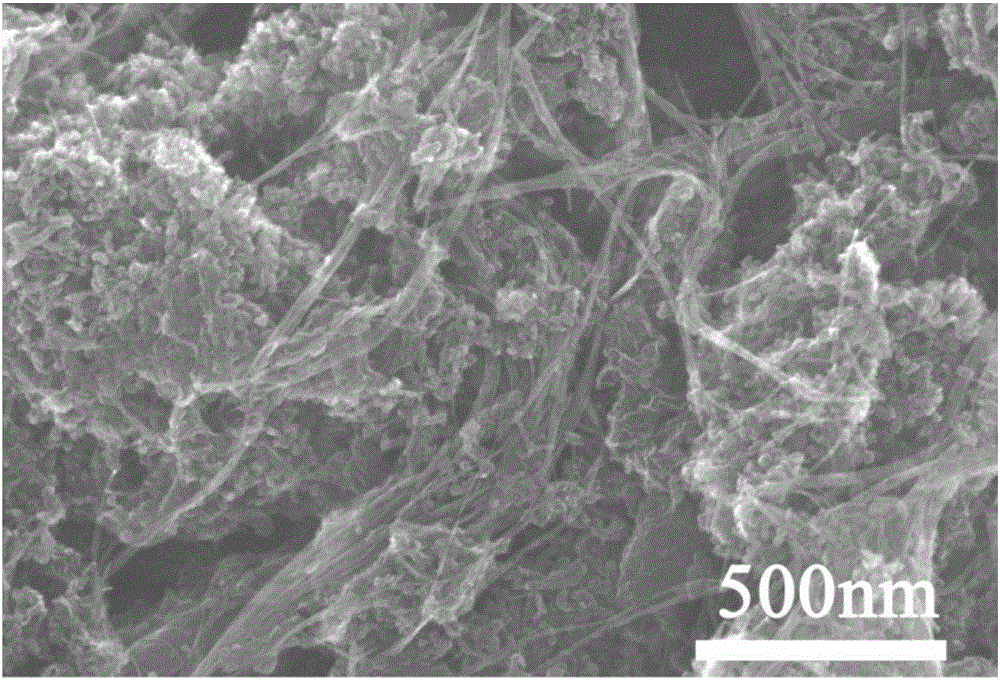

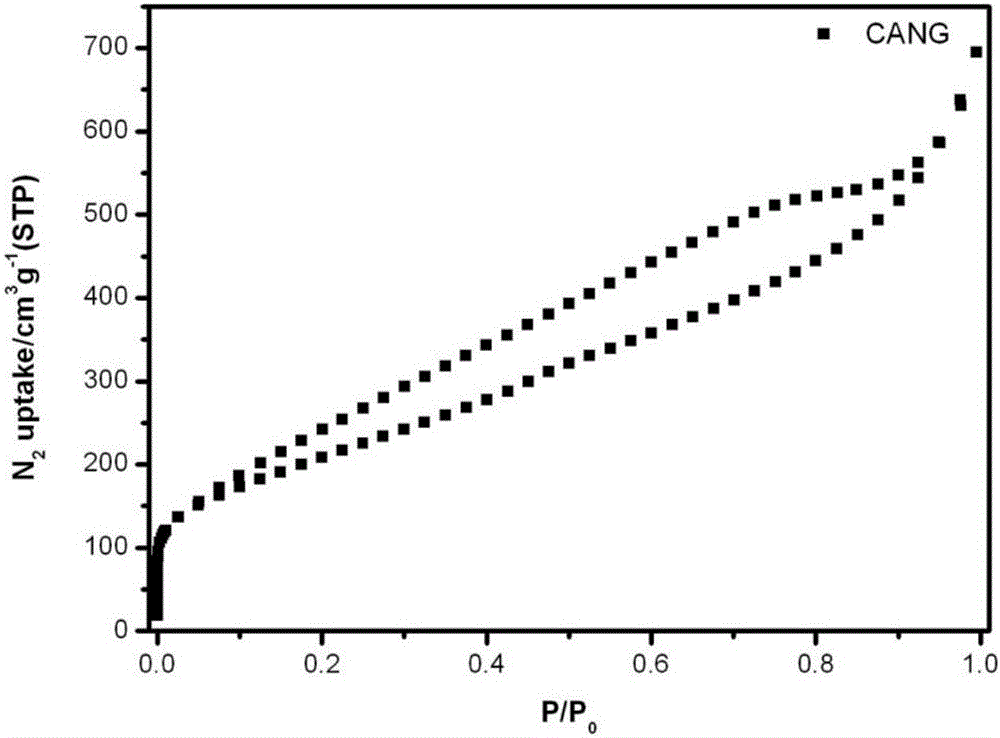

Method used

Image

Examples

Embodiment 1

[0021] 1. Take the improved Hummers method (Jiang G, Goledzinowski M, Comeau FJE, ZarrinH, Lui G, Lenos J, et al. Free-Standing Functionalized Graphene Oxide Solid Electrolytes in Electrochemical Gas Sensors. Advanced Functional Materials. 2016; 26 (11 ): 1729-36.) The graphene oxide synthesized was dissolved in 30mL deionized water, and dispersed uniformly to obtain a graphene oxide dispersion of 2mg / mL.

[0022] 2. Prepare 30 mL of a 1.6 mg / mL sodium dodecylbenzenesulfonate solution, and dissolve carbon nanotubes in the solution. The mass ratio of carbon nanotubes to graphene oxide is 1:3.75.

[0023] 3. Activated carbon is added in the solution of step (2), the mass ratio of activated carbon to graphene oxide is 1:2, and the above-mentioned graphene oxide dispersion is added in the solution.

[0024] 4. Place the solution obtained in step (3) in a ball mill for 3 hours.

[0025] 5. Add melamine to the solution obtained in step (4) under stirring conditions, the mass ratio ...

Embodiment 2

[0029] 1. Dissolve the graphene oxide synthesized by the improved Hummers method in 30mL deionized water and disperse evenly to obtain a 5mg / mL graphene oxide dispersion.

[0030] 2. Prepare 30 mL of 3.75 mg / mL sodium dodecyl sulfate solution, dissolve carbon nanotubes in the above solution, and the mass ratio of carbon nanotubes to graphene oxide is 1:4.

[0031] 3. Activated carbon is added in the solution of step (2), the mass ratio of activated carbon to graphene oxide is 1:3, and the above-mentioned graphene oxide dispersion is added in the solution.

[0032] 4. Place the solution obtained in step (3) in a ball mill for 3 hours.

[0033] 5. Add melamine to the solution obtained in step (4) under stirring conditions. The mass ratio of melamine to graphene oxide is 3:2. Use ultrasonic dispersion for 1h in a system containing zirconia microspheres below 20°C, and stir for 20min Afterwards, the obtained dispersion liquid was transferred into a 100mL reactor, and reacted at 1...

Embodiment 3

[0037] The graphene oxide synthesized by the improved Hummers method was dissolved in 30 mL deionized water and dispersed evenly to obtain a 3 mg / mL graphene oxide dispersion.

[0038] 2. Prepare 30 mL of 3 mg / mL sodium dodecylsulfonate solution, dissolve carbon nanotubes in the above solution, and the mass ratio of carbon nanotubes to graphene oxide is 1:3.

[0039] 3. Activated carbon is added in the solution of step (2), the mass ratio of activated carbon to graphene oxide is 1:3, and the above-mentioned graphene oxide dispersion is added in the solution.

[0040] 4. Place the solution obtained in step (3) in a ball mill for 3 hours.

[0041] 5. Add melamine to the solution obtained in step (4) under stirring conditions. The mass ratio of melamine to graphene oxide is 1.34:1. At a temperature below 20°C, use ultrasonic dispersion for 1 hour in a system containing zirconia microspheres, and stir for 20 minutes. Afterwards, the obtained dispersion liquid was transferred into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com