Phase shift unit and terahertz reflection-type liquid crystal phase shifter formed by phase shift unit

A phase-shifting and liquid crystal layer technology, which is applied to electrical components, waveguide devices, circuits, etc., can solve the problems of system noise performance deterioration, process sensitivity increase, device size reduction, etc., and achieve easy manufacturing process and low manufacturing cost. The effect of low and small bias voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

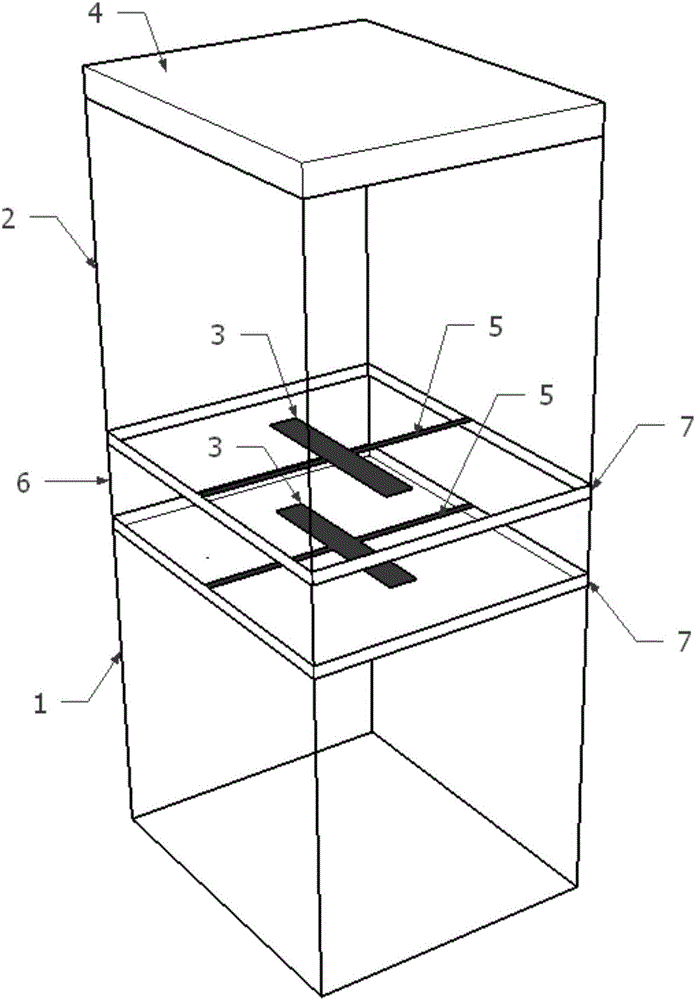

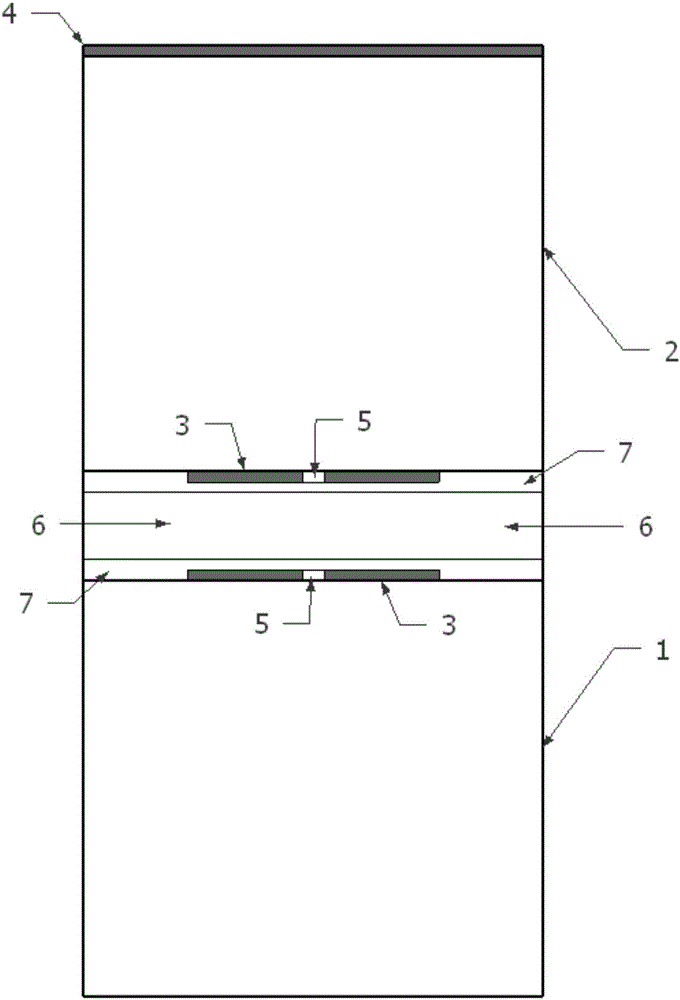

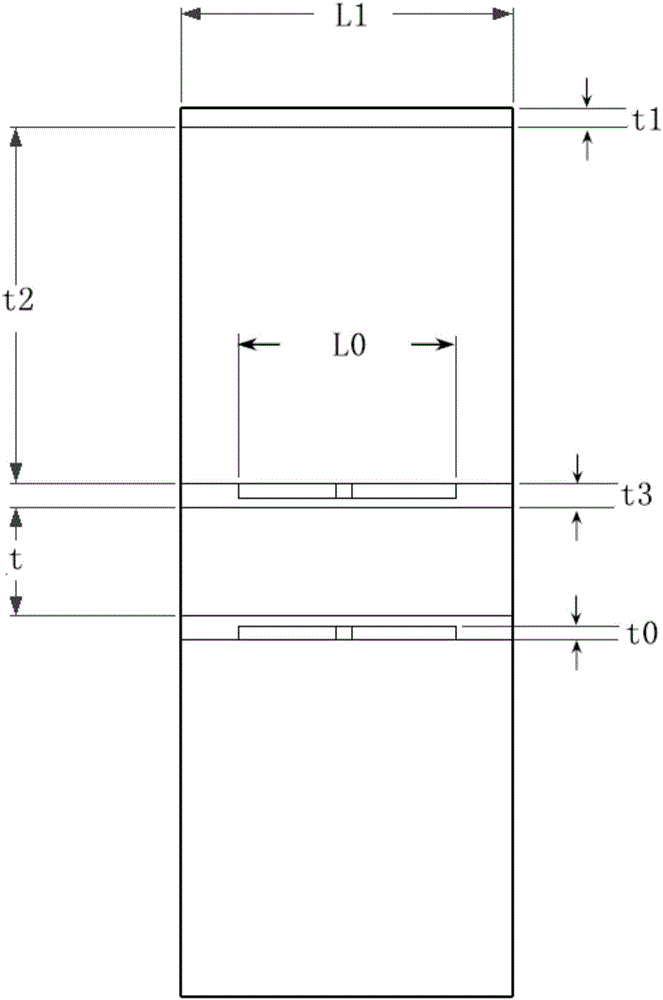

[0027] combine figure 1 , a phase shifting unit, comprising a dielectric substrate, an electrode structure and a liquid crystal layer. Among them, the dielectric substrate is divided into two layers, which are identical in size and shape, and are both made of quartz. The side length of the dielectric substrate 1 and the dielectric substrate 2 is 420 μm, the width is 350 μm, and the thickness is 390 μm. An electrode structure is provided on the surface of the dielectric substrate, and its material is Cu / Au. The opposite side of the dielectric substrate 1 and the dielectric substrate 2 is a dipole patch with a mirror structure. The length is 230 μm, the width is 35 μm, and the thickness is 0.5 μm. The other side of the dielectric substrate 2 is an all-metal reflective structure 4 with a length of 420 μm, a width of 350 μm, and a thickness of 0.5 μm; the width of the metal connection line 5 is 5 μm. A polyimide film 7 is spin-coated on the two microstrip patch electrodes 3, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com