Dual-pack adhesive and structural piece containing same

An adhesive, two-component technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problem of not being able to obtain sufficient adhesive strength, and achieve the goal of maintaining adhesive strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-11

[0087] Synthesis of Oligomers Containing α-Methylstyrene Groups (AMSPU2400)

[0088] 120.60g TMI (3-isopropenyl-α,α-dimethylbenzyl isocyanate; Cytec Industries, Inc.) and 600.00g JEFFAMINE D2000 (diamine-terminated polypropylene glycol, nominal molecular weight: 2000 ; Huntsman Petrochemical Corp.) were mixed and reacted overnight at room temperature without temperature adjustment. The results of IR spectroscopy show that the isocyanate peak is at a frequency of 2,265cm –1 disappears in time, thus confirming the completion of the reaction. In this way, an oligomer comprising α-methylstyrene groups (AMSPU2400) was obtained.

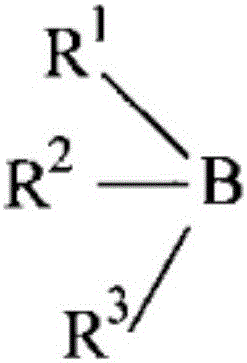

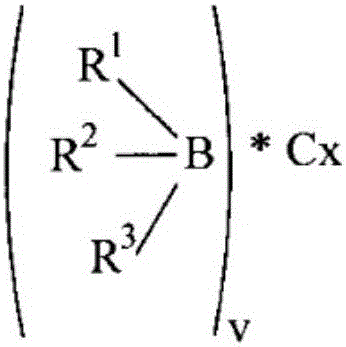

[0089] Initiator (B)

[0090] An amount of 11.87 g of triethylboron / 1,6-hexanediamine complex having a molar ratio of 2:1 was dissolved in 22.03 g of CX-100 (trimethylolpropane tris(3-(2- Propyleneimine)) propionate; DSM NeoResins). Next, 62.30 g of AMSPU2400, 3.60 g of Cab-O-Sil TS-720 (silane-modified fumed silica; Cabot Corp.) and 0.20 g of XC-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com