Abalone flavored essence and preparation method thereof

An abalone and flavor technology, which is applied in the field of food processing, can solve the problems that people with seafood allergies cannot eat, restrict the development direction, and have a strong sense of chemical synthesis, and achieve the effects of rich abalone aroma, wide application to a wide range of people, and a wide range of raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

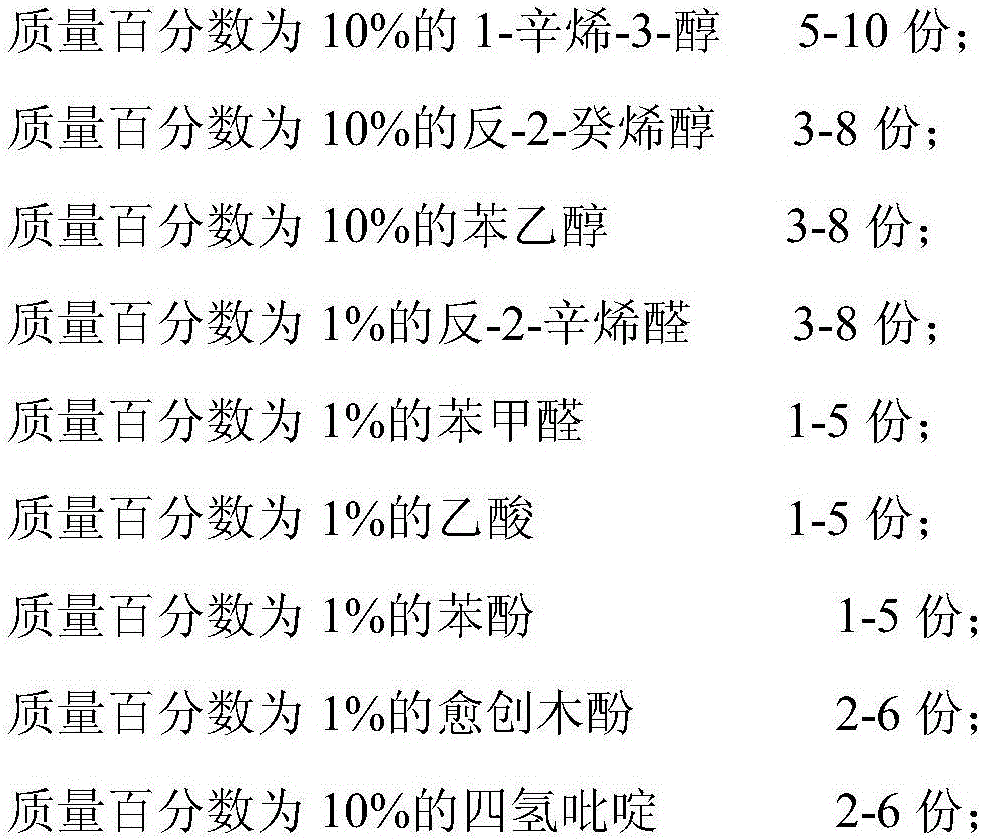

[0033] An abalone flavor essence, its composition and weight parts are as follows:

[0034] 92 parts of thermally reactive abalone flavor cream, 1 part of abalone flavor base;

[0035] The composition and parts by weight of the thermal reaction abalone flavor paste are as follows: 60 parts of abalone mushroom enzymatic hydrolysate, 6 parts of salt, 2 parts of amino acids, 1 part of reducing sugar, 3 parts of corn starch, 1 part of monosodium glutamate, 1 part of white sugar , 1 part of 5'-taste nucleotide disodium and 1 part of yeast extract.

[0036] The preparation method of the abalone mushroom enzymatic hydrolysate is as follows: take abalone mushroom powder, add 10 times the total mass of abalone mushroom powder in water, mix well, treat at 100°C for 6 hours, and then adjust the pH to 4.5 with food grade sodium hydroxide , Then add 1% of the total mass of abalone mushroom powder cellulase and / or hemicellulase, and 2% of the total mass of abalone mushroom powder protease, enzyma...

Embodiment 2

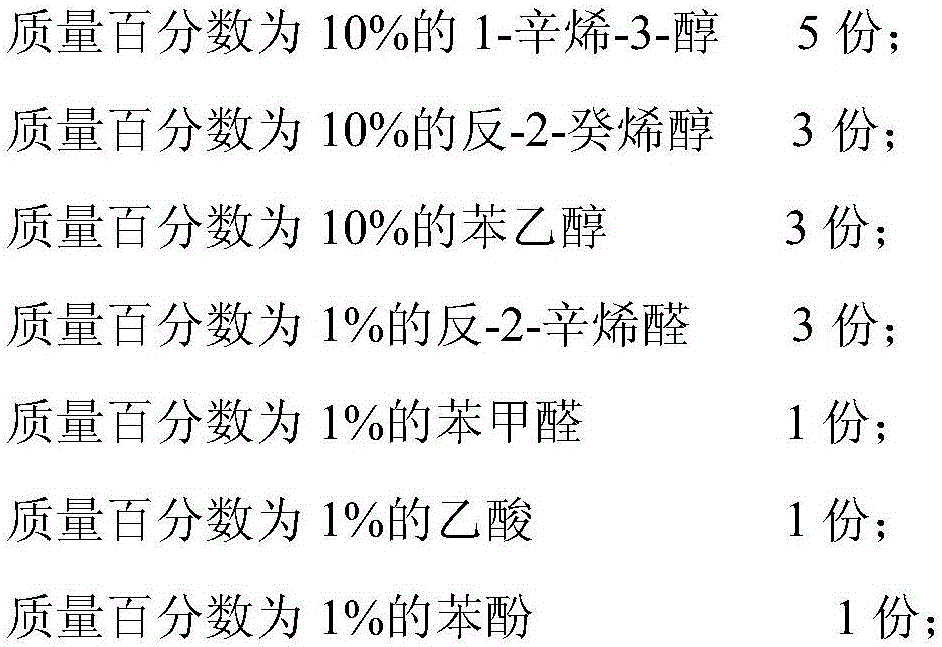

[0049] An abalone flavor essence, its composition and weight parts are as follows:

[0050] 96 parts of thermally reactive abalone flavor cream, 5 parts of abalone flavor base;

[0051] The composition and parts by weight of the thermal reaction abalone flavor paste are as follows: 70 parts of abalone mushroom enzymatic hydrolysate, 11 parts of salt, 5 parts of amino acids, 5 parts of reducing sugar, 4 parts of corn starch, 3 parts of monosodium glutamate, 3 parts of white sugar , 2 parts of 5'-taste nucleotide disodium, 3 parts of yeast extract.

[0052] The preparation method of the abalone mushroom enzymatic hydrolysate is as follows: take abalone mushroom powder, add 15 times the total mass of abalone mushroom powder in water, mix well, treat at 110°C for 4 hours, and then adjust the pH to 5 with food-grade sodium hydroxide , Then add 2% cellulase and / or hemicellulase of the total mass of abalone mushroom powder, and 3% protease of the total mass of abalone mushroom powder, enzy...

Embodiment 3

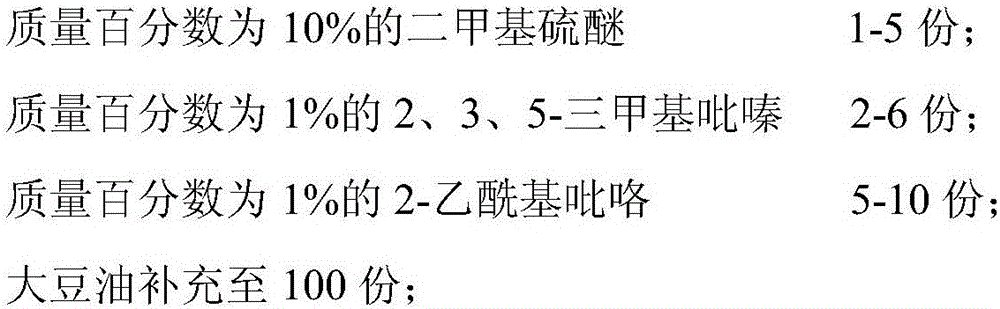

[0064] An abalone flavor essence, its composition and weight parts are as follows:

[0065] 99 parts of heat-reactive abalone flavor cream, 8 parts of abalone flavor base;

[0066] The composition and parts by weight of the thermally reactive abalone flavor cream are as follows: 80 parts of abalone mushroom enzymatic hydrolysate, 15 parts of salt, 8 parts of amino acids, 8 parts of reducing sugar, 6 parts of corn starch, 5 parts of monosodium glutamate, 4 parts of white sugar , 3 parts of 5'-taste nucleotide disodium, 6 parts of yeast extract.

[0067] The preparation method of the abalone mushroom enzymatic hydrolysate is as follows: take abalone mushroom powder, add 20 times the total mass of abalone mushroom powder in water, mix well, treat at 120°C for 2h, and then adjust the pH to 6.5 with food-grade sodium hydroxide , Then add 3% cellulase and / or hemicellulase of the total mass of abalone mushroom powder and 4% protease of the total mass of abalone mushroom powder, enzymatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com