Preparation method of Stropharia rugosoannulata edible fungus flavor bean residue food raw material

A technology of stropharia stropharia and edible fungus, applied in the direction of food science, etc., to achieve the effects of improving appearance and taste, increasing bioavailability, and reducing crude fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

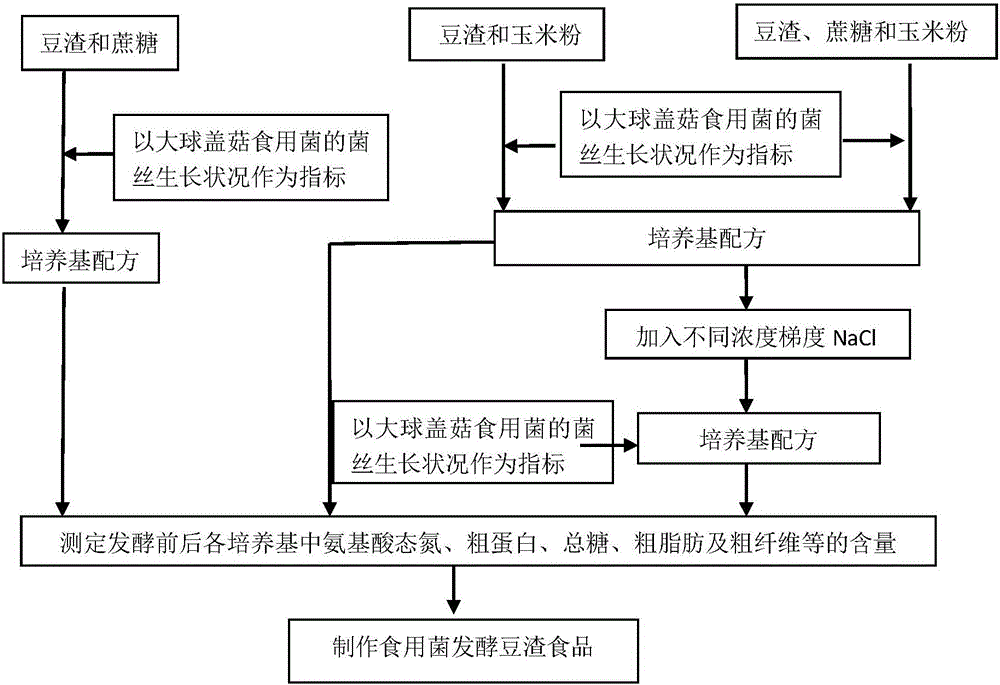

Method used

Image

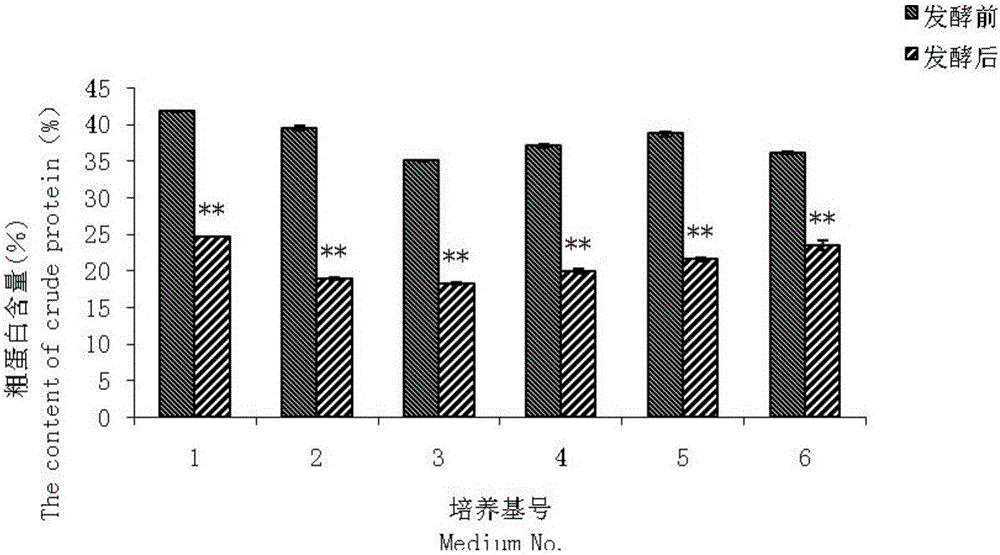

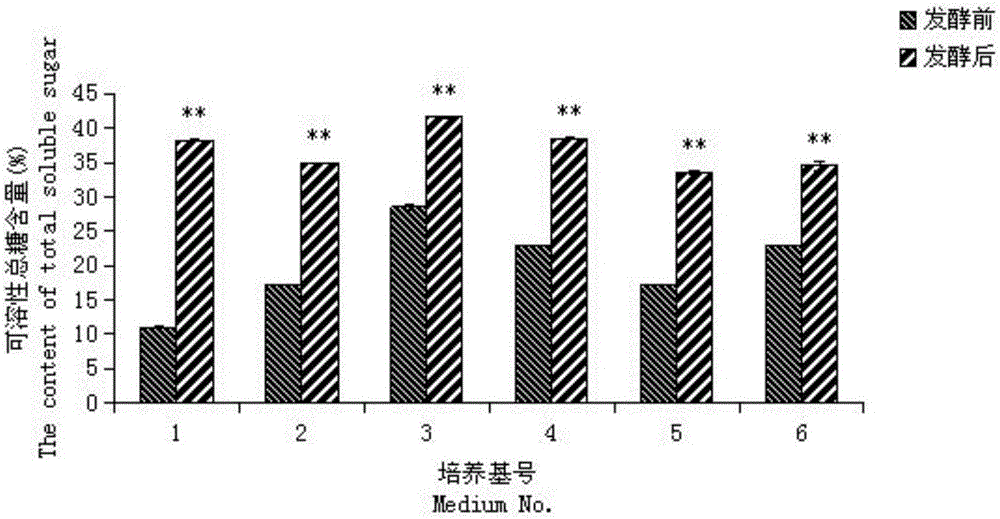

Examples

Embodiment 1

[0032] A method for preparing edible fungus-flavored bean dregs food raw material of Stropharia stropharia, comprising the following steps:

[0033] Step 1: Dried and crushed bean dregs are passed through a 30-mesh sieve, sealed and stored for later use;

[0034] Step 2: inoculate the edible fungus of Stropharia grandis on the PDA slant medium for activation, and cultivate it at 26° C. for 10 days to obtain the slant strain;

[0035] Step 3: 3% glucose, 0.2% peptone, 0.05% MgSO 4 ·7H 2 O, 0.01% CaCl 2 , 0.05% KH 2 PO 4 and the remaining amount of water are mixed uniformly to prepare a liquid culture medium;

[0036] Step 4: add liquid culture medium to the flask, inoculate the slant strain into the liquid seed culture medium, and vibrate at 25°C and 130r / min for 5 days to prepare the liquid strain;

[0037] Step 5: using bean dregs as raw material, adding 80% water by weight (i.e. 20% solid substrate+80% water) to make No. 1 solid medium;

[0038] Step 6: Solid-state fe...

Embodiment 2

[0040] A method for preparing edible fungus-flavored bean dregs food raw material of Stropharia stropharia, comprising the following steps:

[0041] Step 1: Dried and crushed bean dregs are passed through a 30-mesh sieve, sealed and stored for later use;

[0042] Step 2: inoculate the edible fungus of Stropharia grandis on the PDA slant medium for activation, and cultivate it at 26° C. for 10 days to obtain the slant strain;

[0043] Step 3: 3% glucose, 0.2% peptone, 0.05% MgSO 4 ·7H 2 O, 0.01% CaCl 2 , 0.05% KH 2 PO 4 and the remaining amount of water are mixed uniformly to prepare a liquid culture medium;

[0044] Step 4: add liquid culture medium to the flask, inoculate the slant strain into the liquid culture medium, and vibrate at 25°C and 130r / min for 5 days to prepare the liquid strain;

[0045] Step 5: After mixing the bean dregs and corn flour in a weight ratio of 4:1, add 80% water by weight (i.e. 20% solid substrate+80% water), mix well, and make No. 2 solid m...

Embodiment 3

[0048] A method for preparing edible fungus-flavored bean dregs food raw material of Stropharia stropharia, comprising the following steps:

[0049] Step 1: Dried and crushed bean dregs are passed through a 30-mesh sieve, sealed and stored for later use;

[0050] Step 2: inoculate the edible fungus of Stropharia grandis on the PDA slant medium for activation, and cultivate it at 26° C. for 10 days to obtain the slant strain;

[0051] Step 3: 3% glucose, 0.2% peptone, 0.05% MgSO 4 ·7H 2 O, 0.01% CaCl 2 , 0.05% KH 2 PO 4 and the remaining amount of water are mixed uniformly to prepare a liquid culture medium;

[0052] Step 4: add liquid culture medium to the flask, inoculate the slant strain into the liquid culture medium, and vibrate at 25°C and 130r / min for 5 days to prepare the liquid strain;

[0053] Step 5: After mixing bean dregs and sucrose in a weight ratio of 4:1, add 80% water by weight (i.e. 20% solid matrix + 80% water), mix well, and make No. 3 solid medium;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com