Method for preparing integrated catalyst for low-temperature catalytic oxidation of formaldehyde

A low-temperature catalysis and catalyst technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of poor mass transfer resistance, high pressure drop, difficult plasticity and other problems, to achieve the effect of good adsorption performance, pressure drop, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

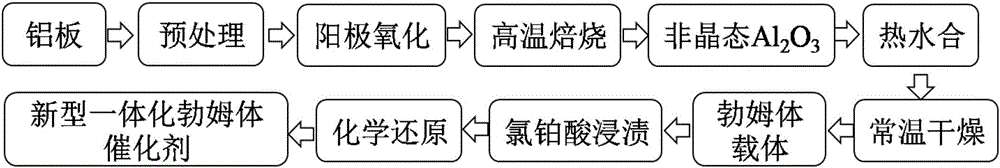

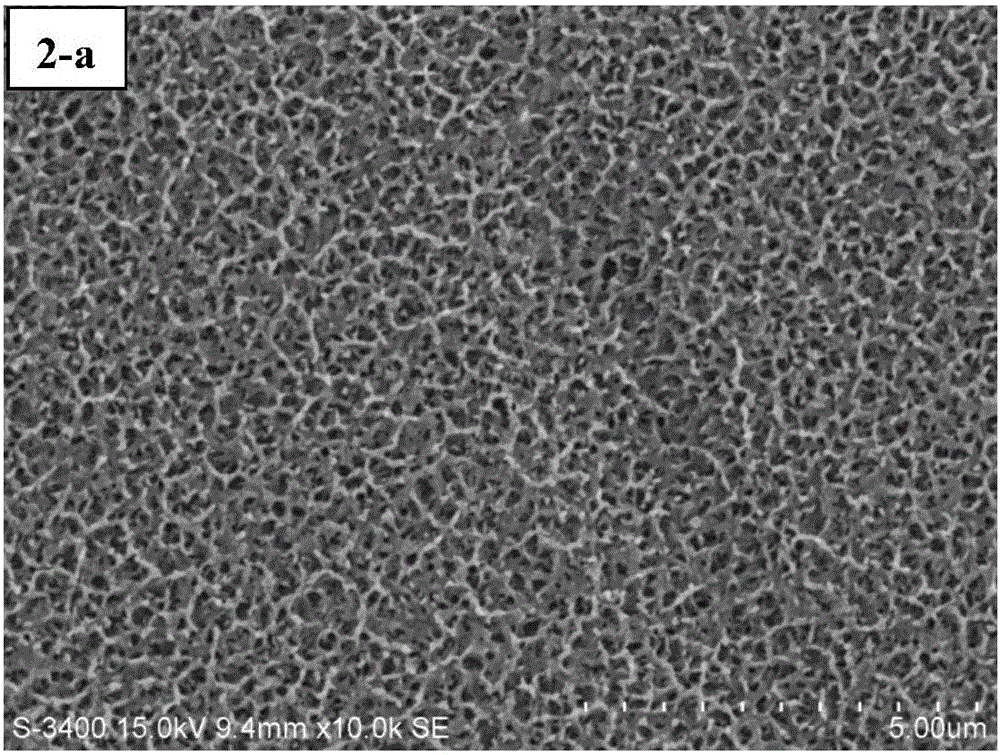

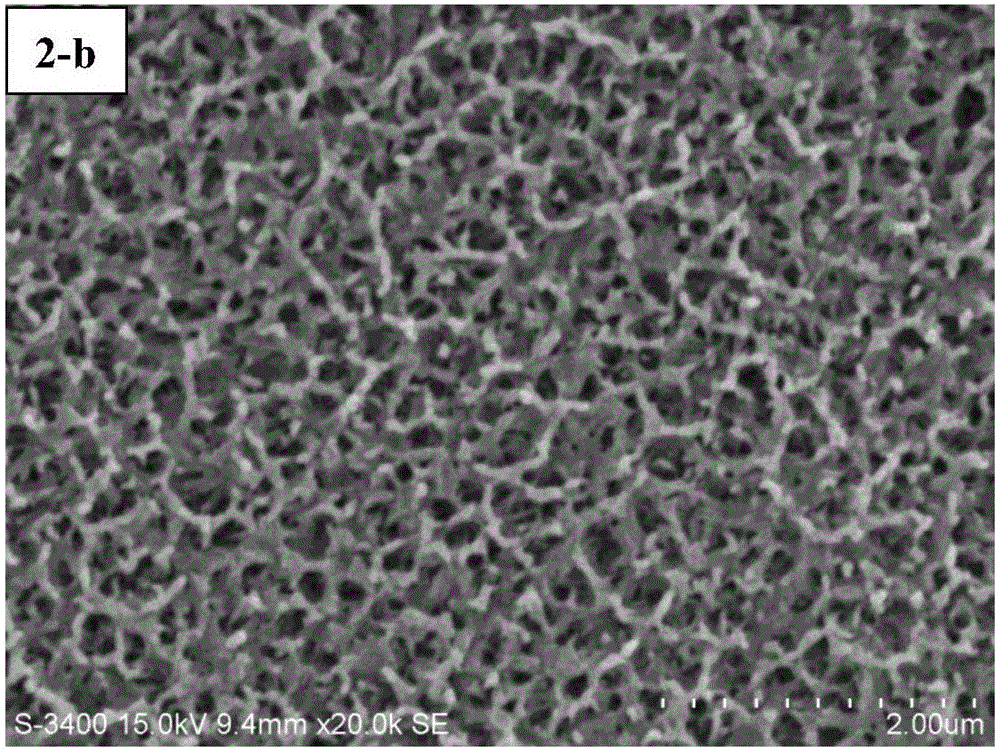

[0030] with 10wt% NaOH solution and 10wt% HNO 3 After pre-treating the aluminum plate with the solution for 4 minutes and 2 minutes, put it into the anodizing tank for anodic oxidation, and place the aluminum plate at a current density of 50A / m at 20°C 2 , anodized in 0.1-0.8mol / L oxalic acid solution for 8-16h, air-dried and roasted at 350°C for 1h; then hydrated in deionized water at 95°C for 60-70min, dried at room temperature for 12h to obtain boehmite;

[0031] The obtained Boehm bodies were placed in concentrations of 0.1g / L, 0.2g / L, 0.3g / L, 0.4g / L, 0.5g / L, 0.6g / L, 0.7g / L, 0.8g / L chloroplatinic acid solution, immersed at 25°C for 4h, and dried at room temperature for 12h; the loaded boehmite was placed in a sodium borohydride solution with a concentration of 0.05mol / L, reduced at 25°C for 1h, and dried at room temperature for 12h , to obtain an integrated catalyst. The impact of the obtained catalyst load and the concentration of chloroplatinic acid on the platinum loa...

Embodiment 2

[0037] with 10wt% NaOH solution and 10wt% HNO 3 After pre-treating the aluminum plate with the solution for 4 minutes and 2 minutes, put it into the anodizing tank for anodic oxidation, and place the aluminum plate at a current density of 50A / m at 20°C 2 , anodized in 0.4mol / L oxalic acid solution for 12 hours, air-dried and roasted at 350°C for 1 hour; then hydrated in deionized water at 80°C for 60 minutes, dried at room temperature for 12 hours to obtain boehmite;

[0038] Place the obtained Boehmite in chloroplatinic acid solution with a concentration of 0.1g / L, respectively immerse at 25°C for 1, 2, 4, 6, and 8 hours, and dry at room temperature for 12h; the loaded Boehmite Place in a sodium borohydride solution with a concentration of 0.05 mol / L, reduce at 25° C. for 1 h, and dry at room temperature for 12 h to obtain an integrated catalyst. The resulting effect of immersion time on platinum loading is shown in Table 2.

[0039] Table 2 Effect of immersion time on plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com