Silicon dioxide nanowire preparation method

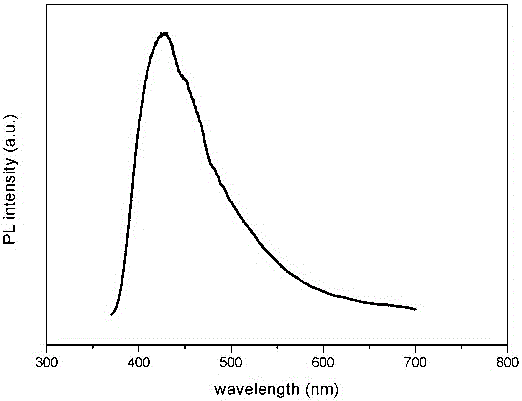

A silicate glass, a technology for removing silicate, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of increased preparation cost, high corrosion of the solution, cumbersome steps, etc., and achieves good blue light emission characteristics, Simple process and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment provides a method for preparing SiO from silicate glass 2 The method for nanowires specifically comprises the following steps:

[0025] (1) Pre-treatment: Use 99% acetone and distilled water to clean the glass ultrasonically for 5 minutes each to remove the surface of the glass (the main components are Si: 74%, Na: 16%, Ca: 9%, Al: 1%). Dust and oil.

[0026] (2) Put 10g of pre-treated glass into 100ml of ammonia water for corrosion, the concentration of ammonia water is 1mol / L, the temperature is 180°C, and the corrosion time is 4 h.

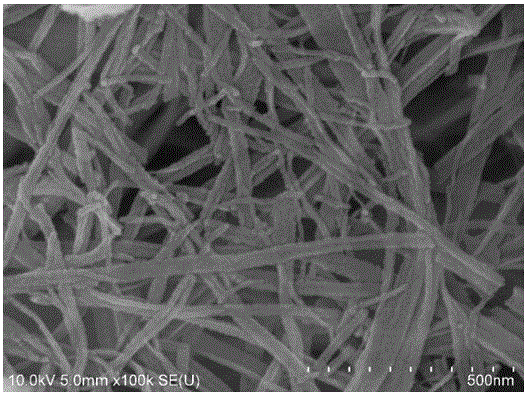

[0027] (3) Take out the glass after corrosion, centrifuge the precipitate, pour off the supernatant, wash with distilled water, repeat centrifugation and washing 5 times, and then dry the precipitate at 80°C, the precipitate is SiO 2 Nanowires. figure 1 For the obtained SiO 2 Scanning electron microscope image of the nanowire, from which it can be seen that the prepared SiO 2 The diameter of the nanowire is between 1...

Embodiment 2

[0029] This embodiment provides a method for preparing SiO from silicate glass 2 The method for nanowires specifically comprises the following steps:

[0030] (1) Pretreatment: Use 99% acetone and distilled water to clean the glass ultrasonically for 5 minutes each to remove the surface of the glass (mainly composed of Si: 76%, Na: 16%, Ca: 7%, Al: 1%). Dust and oil.

[0031] (2) Put 15g of pre-treated glass into 100ml of ammonia water for corrosion, the concentration of ammonia water is 1.25 mol / L, the temperature is 160°C, and the corrosion time is 7 h.

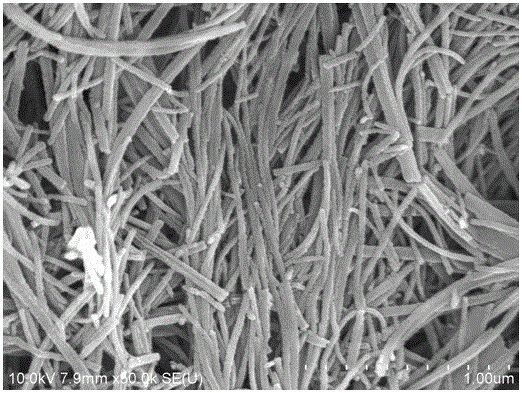

[0032] (3) Take out the glass after corrosion, centrifuge the precipitate, pour off the supernatant, wash with distilled water, repeat centrifugation and washing 5 times, and then dry the precipitate at 80°C, the precipitate is SiO 2 Nanowires. image 3 For the obtained SiO 2 Scanning electron microscope image of the nanowire, from which it can be seen that the prepared SiO 2 The diameter of the nanowires is between 20...

Embodiment 3

[0034] This embodiment provides a method for preparing SiO from silicate glass 2 The method for nanowires specifically comprises the following steps:

[0035] (1) Pretreatment: Use 99% acetone and distilled water to clean the glass ultrasonically for 5 minutes each to remove the surface of the glass (mainly composed of Si: 75%, Na: 16%, Ca: 7%, Al: 2%). Dust and oil.

[0036] (2) Put 20g of pre-treated glass into 100ml of ammonia water for corrosion, the concentration of ammonia water is 1.5mol / L, the temperature is 170°C, and the corrosion time is 12 h;

[0037] (3) Take out the glass after corrosion, centrifuge the precipitate, pour off the supernatant and wash with distilled water, repeat centrifugation and washing 5 times, and then dry the precipitate at 80°C, the precipitate is SiO 2 Nanowires. Figure 5 For the obtained SiO 2 Scanning electron microscope image of the nanowire, from which it can be seen that the prepared SiO 2 The diameter of the nanowires is between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com