Preparation method of nitrogen-doped porous carbon rod capacitance desalting electrode

A technology of nitrogen-doped porous carbon and porous carbon, applied in chemical instruments and methods, water/sewage treatment equipment, electrochemical water/sewage treatment, etc., can solve the problem of increasing synthesis cost, prolonging synthesis cycle, unfavorable large-scale production, etc. problems, achieve good conductivity, mild conditions, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of Capacitive Desalting Electrode

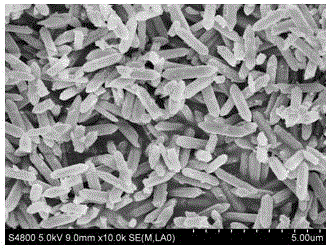

[0029] Dissolve 0.5mol of 2-aminoterephthalic acid and 0.5mol of ferric chloride hexahydrate in 50ml of deionized water at room temperature, stir for 10 minutes, transfer to a 100mL hydrothermal kettle, and place in a constant temperature drying oven at 100°C Heat for 6 hours. The obtained sample is centrifugally washed and dried to obtain MIL-88-NH 2 ; The resulting MIL-88-NH 2 Place in a tube furnace under a nitrogen atmosphere at a heating rate of 2°C / min to 700°C for 2 hours. The obtained carbonized product was etched with 5M hydrochloric acid, washed and dried to obtain a nitrogen-doped spindle-shaped porous carbon rod (named NCRs-700), see figure 1 . Using nitrogen adsorption and desorption, X-ray diffraction and photoelectron spectroscopy to analyze the synthesized porous carbon rods, it is proved that it has the characteristics of wide pore size, high graphitization, and high nitrogen doping content, see Tab...

Embodiment 2

[0034] 1) Preparation of Capacitive Desalting Electrode

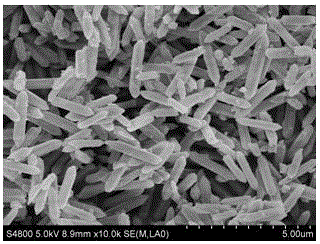

[0035] Dissolve 0.5mol of 2-aminoterephthalic acid and 0.5mol of ferric chloride hexahydrate in 50ml of deionized water at room temperature, stir for 10 minutes, transfer to a 100mL hydrothermal kettle, and place in a constant temperature drying oven at 100°C Heat for 6 hours. The obtained sample is centrifugally washed and dried to obtain MIL-88-NH 2 ; The resulting MIL-88-NH 2 Place in a tube furnace under a nitrogen atmosphere at a heating rate of 2°C / min to 800°C for 2 hours. The obtained carbonized product was etched with 5M hydrochloric acid, washed and dried to obtain a nitrogen-doped spindle-shaped porous carbon rod (named NCRs-800), see figure 2 . Using nitrogen adsorption and desorption, X-ray diffraction and photoelectron spectroscopy to analyze the synthesized porous carbon rods, it is proved that it has the characteristics of wide pore size, high graphitization, and high nitrogen doping content, see Ta...

Embodiment 3

[0040] 1) Preparation of Capacitive Desalting Electrode

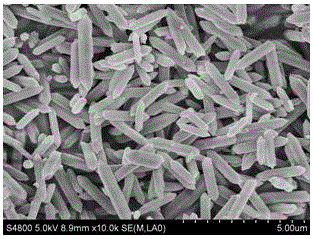

[0041] Dissolve 0.5mol of 2-aminoterephthalic acid and 0.5mol of ferric chloride hexahydrate in 50ml of deionized water at room temperature, stir for 10 minutes, transfer to a 100mL hydrothermal kettle, and place in a constant temperature drying oven at 100°C Heat for 6 hours. The obtained sample is centrifugally washed and dried to obtain MIL-88-NH 2 ; The resulting MIL-88-NH 2 Place in a tube furnace under a nitrogen atmosphere at a heating rate of 2°C / min to 900°C for 2 hours. The obtained carbonized product was etched with 5M hydrochloric acid, washed and dried to obtain a nitrogen-doped spindle-shaped porous carbon rod (named NCRs-900), see image 3 . Using nitrogen adsorption and desorption, X-ray diffraction and photoelectron spectroscopy to analyze the synthesized porous carbon rods, it is proved that it has the characteristics of wide pore size, high graphitization, and high nitrogen doping content, see Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com