Water emulsion polymerization method for preparing meltable fluorine-containing polymer

A polymerization method and polymer technology, applied in the field of fluorine-containing polymer synthesis, can solve the problems of poor water solubility, large dosage, and low industrial application value, and achieve the effects of low volatile content and no discoloration of volatile content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 3.8 L of deionized water and 12 ml of 40% perfluorooctanoic acid ammonium salt (PFOA) were added to a polymerization kettle with a total volume of 6.0 L and equipped with an impeller agitator system. Then the reactor was evacuated and replaced until the oxygen content was less than 28ppm. Then, 600 g of TFE and FEP mixed monomers were initially put into the reactor, wherein the mass proportion of TFE was 25%. Raise the temperature of the reactor to 98-100°C, inject 30ml of ammonium persulfate with a concentration of 2.5% at a rate of 2.3ml / min as an initial initiator, and inject a mixture of 0.01 % concentration perfluorohexyl ammonium acetate chain transfer agent ammonium persulfate initiator, and additional reaction monomer, control the pressure in the reactor to about 3.5mpa. After feeding 1.3kg of TFE monomer, stop the feeding of initiator and chain transfer agent. Maintain the pressure of the reactor and add additional reaction monomers, stop the reaction after 4...

Embodiment 2-4

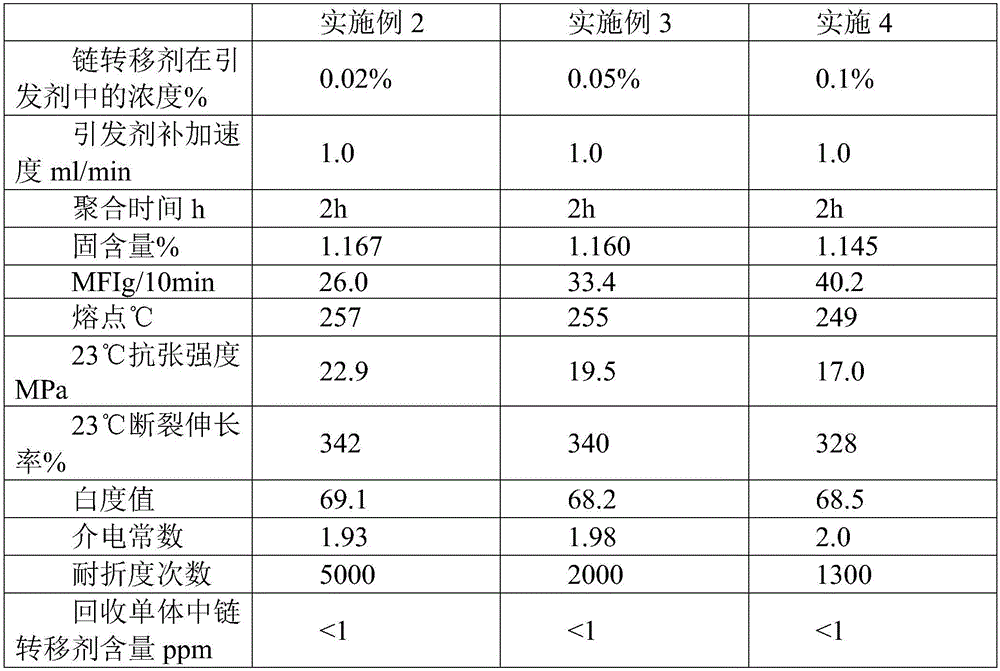

[0032] In embodiment 2,3 and 4, polymer is prepared according to the method for embodiment 1, difference is to change the amount of perfluorohexyl ammonium acetate chain transfer agent, polymer is analyzed in the same manner as embodiment 1, the result Listed in Table 1

[0033] Table 1

[0034]

[0035] According to the above chart, it can be seen that increasing the amount of chain transfer agent increases the chain transfer efficiency and affects the polymerization reaction speed, and the low molecular weight directly leads to a sharp increase in the melt index, and also reduces the mechanical strength of the polymer to a certain extent. , Therefore, generally preferred chain transfer agent dosage is 0.5 ~ 2g / kg polymer.

Embodiment 5

[0037] 3.8 L of deionized water was added to a polymerization tank with a total volume of 6.0 L and equipped with an impeller agitator system, and 12 ml of 40% perfluorooctanoic acid ammonium salt (PFOA) was added, and then the reactor was evacuated and replaced until the oxygen content was less than 28 ppm. . Add 50ml of PPVE and 1g of perfluorohexyl ammonium acetate, raise the temperature to 65°C, then put TFE monomer into the reactor to 0.5MPa, then pump 30ml of ammonium persulfate with a concentration of 2.5% at a speed of 2.3ml / min As the initial initiator, the polymerization starts the reaction. During the reaction period, add TFE monomer, control the pressure in the reactor to about 0.5-0.6MPa, and continue to add ammonium persulfate initiator at a speed of 1.5ml / min. After the additional polymerization is completed, the stirring is stopped, and the remaining monomers in the kettle are recovered. After the reaction kettle was under normal pressure, 3.1 kg of PFA dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com