A kind of bacterial strain and synthetic method utilizing chitin to synthesize pha and application thereof

A chitin and strain technology, applied in chemical instruments and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of high cost of bioplastics, environmental pollution, etc., and achieve low water treatment costs and reduced production. Effects on cost, broad industry and development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

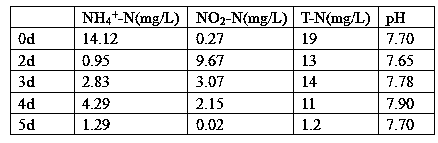

Image

Examples

Embodiment 1

[0020] A method for synthesizing PHA using chitin, the specific operation method includes: (1) preparing chitin into a colloidal solution, and adjusting the pH value to 6.0, adding 5% compound enzyme preparation, and performing enzyme degradation on a shaking table at 60°C, The degradation time is 8 hours, and the degradation product is flocculated, precipitated, and filtered to obtain the enzymatic hydrolysis product; (2) Pseudomonas YJY25 is activated in the seed medium, the activation condition is 30°C, the shaking table is 200r / min, and the activation is 48h; After activation, the bacterial liquid is inserted into the fermentation culture with an inoculum of 1.0% (v%) for cultivation, and then inoculated into the medium with the enzymatic hydrolysis product obtained in step (1) as the only carbon source for cultivation. The conditions are temperature 35°C, pH 7.0, and culture time 48 hours; (3) The culture (that is, the fermentation product) obtained in step (2) undergoes c...

Embodiment 2

[0023] A method for synthesizing PHA from chitin. The specific operation method includes: (1) preparing chitin into a colloidal solution, adjusting the pH value to 5.0, adding 15% compound enzyme preparation, and performing enzyme degradation on a shaking table at 50°C. The degradation time is 10 hours, and the degradation product is flocculated, precipitated, and filtered to obtain the enzymatic hydrolysis product; (2) Pseudomonas YJY25 is activated in the seed medium, the activation condition is 35°C, the shaking table is 250r / min, and the activation is 24h; After activation, the bacterial solution was inserted into the fermentation culture with an inoculum of 2.0% (v%) for cultivation, and then inoculated into the culture medium with the enzymatic hydrolysis product obtained in step (1) as the only carbon source for cultivation. The conditions are temperature 30°C, pH 7.2, and culture time 50 hours; (3) The culture obtained in step (2) undergoes cell wall crushing, flocculat...

Embodiment 3

[0026] A method for synthesizing PHA using chitin, the specific operation method includes: (1) preparing chitin into a colloidal solution, and adjusting the pH value to 6.5, adding 20% compound enzyme preparation, and performing enzyme degradation on a shaking table at 35°C, The degradation time was 1 hour, and the degradation product was flocculated, precipitated, and filtered to obtain the enzymatic hydrolysis product; (2) Pseudomonas YJY25 was activated in the seed medium, the activation condition was 32°C, the shaking table was 230r / min, and the activation was 35 hours; After activation, the bacterial solution was inserted into the fermentation culture with an inoculum of 1.5% (v%) for cultivation, and then inoculated into the medium with the enzymatic hydrolyzate obtained in step (1) as the only carbon source for cultivation. The conditions are temperature 25°C, pH 7.5, and culture time 60 hours; (3) The culture obtained in step (2) undergoes cell wall crushing, floccula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com