Preparation method of nanocellulose-ZnO conductive hybrid material having P/N heterojunction and used for rapid gas sensing

A nanocellulose, gas sensing technology, applied in the direction of zinc oxide/zinc hydroxide, oxide conductors, non-metallic conductors, etc., can solve the problems of poor anti-interference ability, low sensitivity, poor selectivity and stability, etc. The effects of stable electrical conductivity, high gas sensing accuracy and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

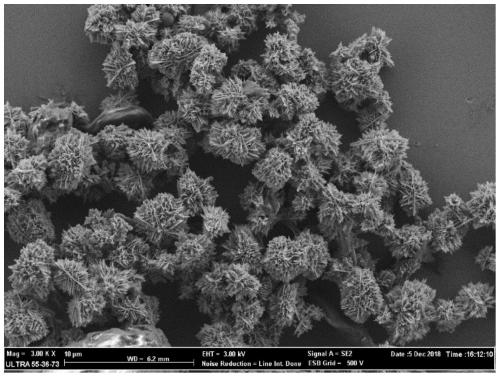

Image

Examples

Embodiment 1

[0031] Add 1g CNC to Zn(NO 3 ) 2 ·6H 2 O solution (0.1mol / L, 20mL) was mixed; the pH value of the mixture was adjusted to 12.5 using NaOH solution; the solution was transferred to a 50mL Teflon-lined stainless steel reactor and reacted at 80°C After 24 hours, the reactor was rapidly cooled to room temperature, centrifuged and washed with water to obtain the sample CNC-ZnO; 0.014g polyvinylpyrrolidone (PVP) and 0.12g CNC-ZnO were added to 1.4mL of ethanol deionized mixed solution (v / v= 9:1), add 0.14g of aniline and 1.5mL of HCl (0.1mol / L) to the mixed solution, and then sonicate for 10min; add 1.2mL of ammonium persulfate ((NH 4 ) 2 S 2 o 8 , 0.5g / mL), after 1h of reaction in the dark, washed several times with deionized water to finally obtain the CNC-ZnO conductive hybrid material.

Embodiment 2

[0033] Add 1g CNC to ZnCl 2 Solutions (0.01mol / L, 10mL) were mixed; the pH value of the mixture was adjusted to 9 using RbOH solution; the solution was transferred to a 50mL polytetrafluoroethylene-lined stainless steel reactor, and reacted at 45°C, After 12 hours, the reaction kettle was rapidly cooled to room temperature, centrifuged and washed with water to obtain the sample CNC-ZnO; 0.003g of PVP and 0.03g of CNC-ZnO were added to 5mL of ethanol deionized mixed solution (v / v=8:2), and mixed Add 0.01g pyrrole and 0.1mL H to the solution 2 SO 4 (1mol / L) and sonicate for 20min; add 0.01mL potassium persulfate (K 2 S 2 o 8 , 0.01g / mL), after reaction in the dark for 0.5h, washed several times with deionized water to finally obtain the CNC-ZnO conductive hybrid material.

Embodiment 3

[0035] Add 1g CNC to ZnSO 4 Solutions (1mol / L, 100mL) were mixed; the pH value of the mixture was adjusted to 15 using LiOH solution; the solution was transferred to a 50mL polytetrafluoroethylene-lined stainless steel reactor, and reacted at 95°C for 16 After one hour, the reaction kettle was rapidly cooled to room temperature, centrifuged and washed with water to obtain the sample CNC-ZnO; 0.05g PVP and 0.3g CNC-ZnO were added to 0.5mL ethanol deionized mixed solution (v / v=7:3), and mixed Add 5g thiophene and 10mL HClO to the solution 4 (5mol / L) and sonicate for 30min; add 3mL sodium persulfate (Na 2 S 2 o 8 , 5g / mL), after 2h of reaction in the dark, washed several times with deionized water to finally obtain the CNC-ZnO conductive hybrid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com