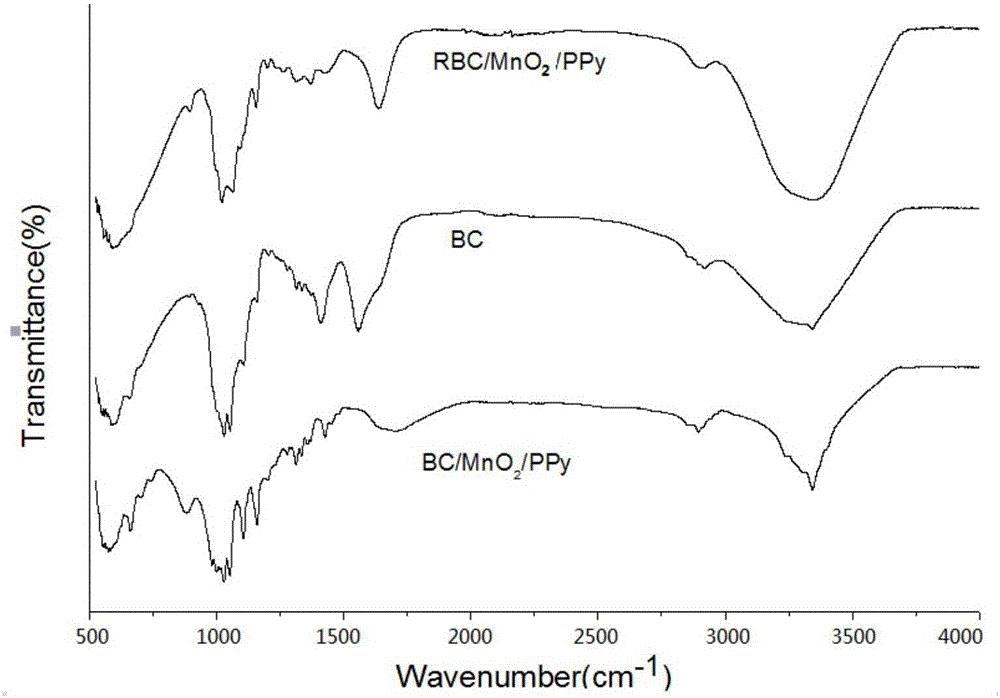

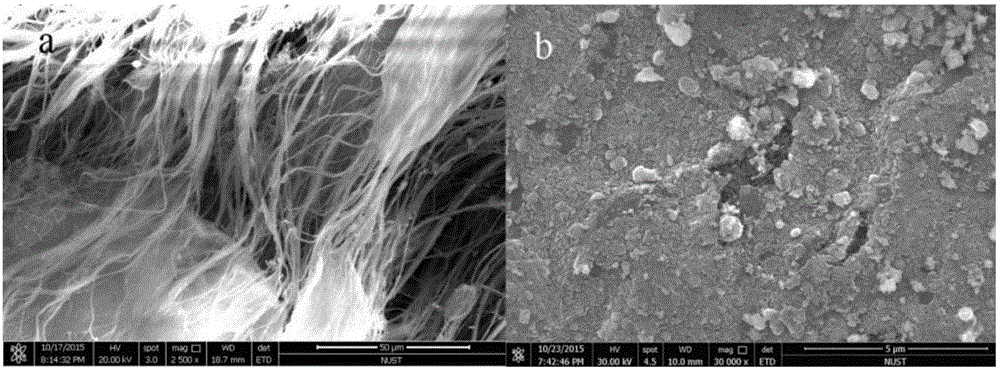

Bacterial cellulose/manganese dioxide/polypyrrole composite film and preparation method thereof

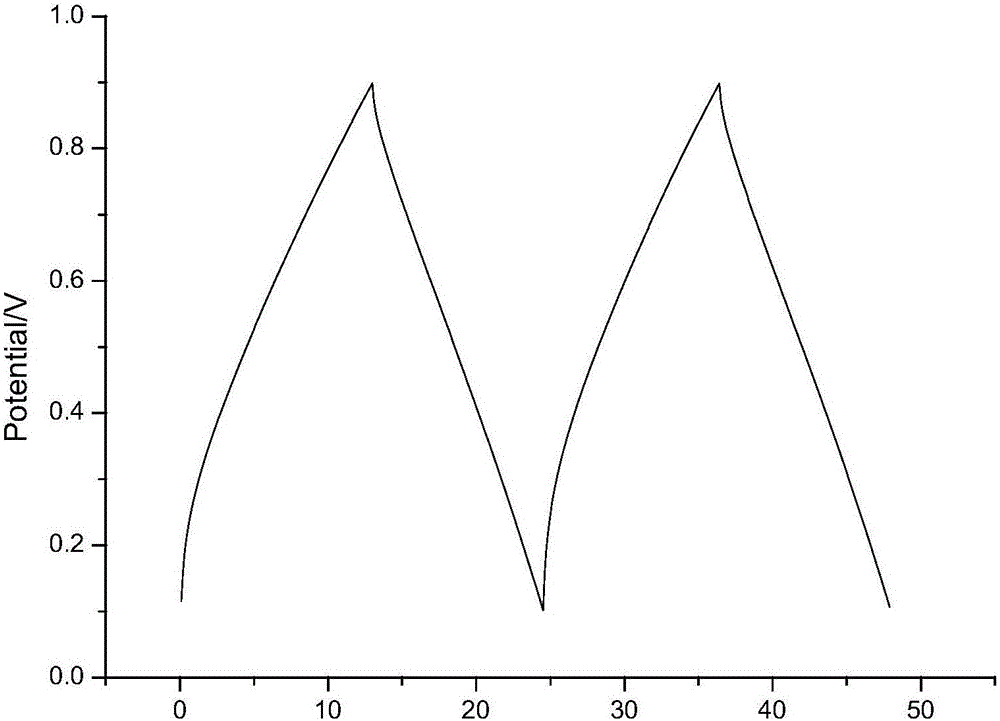

A technology of bacterial cellulose and manganese dioxide, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of low degree of compounding, high energy consumption, fragile membrane, etc., and achieve uniform and compact compounding and good biocompatibility. , the effect of good capacitance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The crude bacterial cellulose obtained by dynamic fermentation was put into 1mol / L NaOH and boiled for 60 minutes, washed with deionized water until the cellulose became white, and dried for 2 hours.

[0025] Add 2 g of pyrrole to 500 ml of 0.2% potassium permanganate solution with a mass concentration and stir and mix. During this process, pyrrole is oxidized and polymerized by potassium permanganate to form polypyrrole, and potassium permanganate is reduced to manganese dioxide. Add 0.1 g of dried bacterial cellulose to the above-mentioned mixed liquid, and ultrasonically stir and mix for 20 minutes, and finally obtain a uniformly mixed bacterial cellulose / manganese dioxide / polypyrrole mixed liquid. Finally, the mixed liquid is filtered under negative pressure, and the filtration surface density is 10g / m 2 The filter cake was washed with 75% ethanol until the filtrate became colorless and transparent, and the pH was neutral, and finally a bacterial cellulose / manganese dio...

Embodiment 2

[0028] The crude bacterial cellulose obtained by dynamic fermentation was put into 1mol / L NaOH and boiled for 60 minutes, washed with deionized water until the cellulose became white, and dried for 4 hours.

[0029] Add 5 g of pyrrole to 200 ml of potassium permanganate solution with a mass concentration of 0.5%, and stir and mix. During this process, the pyrrole is oxidized and polymerized by potassium permanganate to form polypyrrole, and the potassium permanganate is reduced to manganese dioxide. Add 0.07 g of dried bacterial cellulose to the above-mentioned mixed solution, and ultrasonically stir and mix for 25 minutes to finally obtain a uniformly mixed bacterial cellulose / manganese dioxide / polypyrrole mixed solution. Finally, the mixed liquid is filtered under negative pressure, and the filtration surface density is 15g / m 2 The filter cake is washed with 75% ethanol until the filtrate becomes colorless and transparent, and the pH is neutral, and finally a bacterial cellulose...

Embodiment 3

[0032] The crude bacterial cellulose obtained by dynamic fermentation was boiled in 1mol / L NaOH for 60 minutes, washed with deionized water until the cellulose became white, and dried for 5 hours.

[0033] Add 10 g of pyrrole to 100 ml of 1% potassium permanganate solution with a mass concentration, and stir and mix. In this process, pyrrole is oxidized and polymerized by potassium permanganate to form polypyrrole, and potassium permanganate is reduced to manganese dioxide. Add 0.05 g of dry bacterial cellulose to the above-mentioned mixed liquid, and ultrasonically stir and mix for 20 minutes, and finally obtain a uniformly mixed bacterial cellulose / manganese dioxide / polypyrrole mixed liquid. Finally, the mixed liquid is filtered under negative pressure, and the filtration surface density is 10g / m 2 The filter cake is washed with 75% ethanol until the filtrate becomes colorless and transparent, and the pH is neutral, and finally a bacterial cellulose / manganese dioxide / polypyrrole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com