Preparation method of flexible man-machine interaction bionic fabric

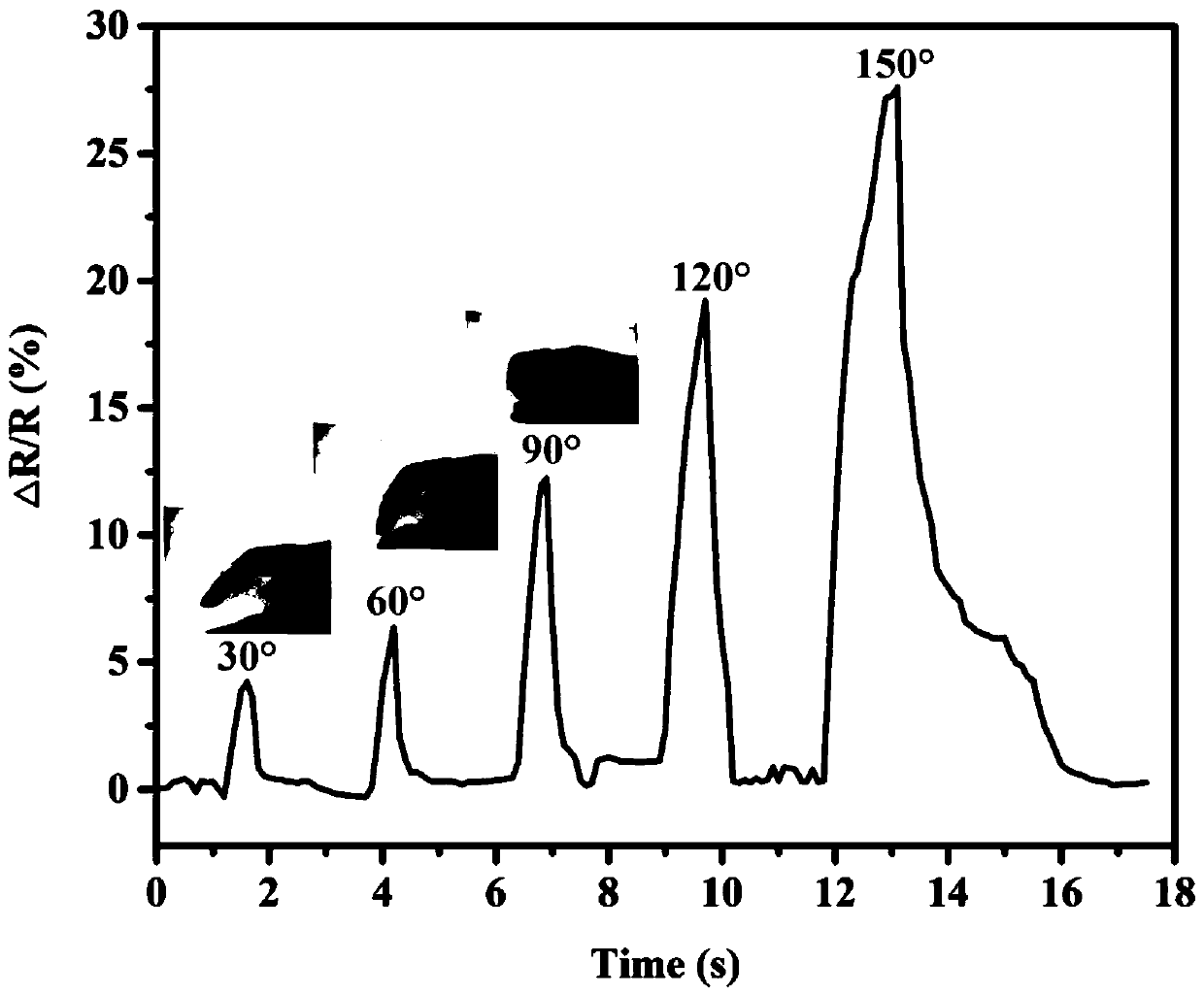

A human-computer interaction, bionic fabric technology, applied in the field of bionic sensing fabric preparation, can solve the problems of poor flexibility, inability to perform human-computer interaction, no self-healing performance, etc., and achieves simple preparation method, high sensing accuracy, and electrical conductivity. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

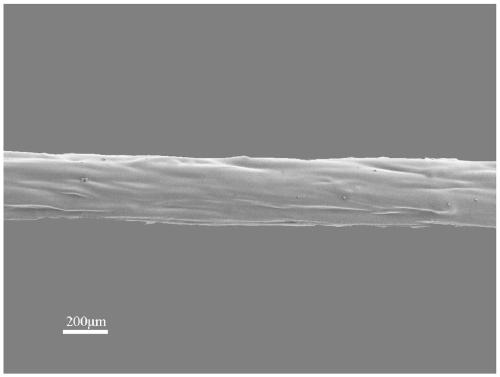

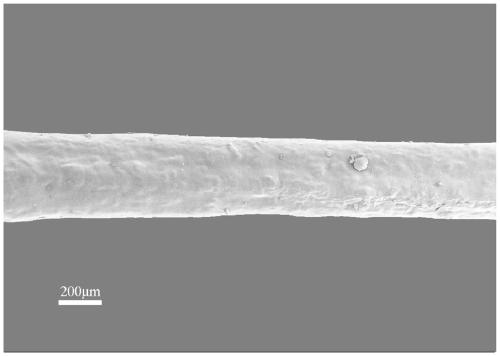

[0037]Cut 5 pieces of silk with a length of 20 cm and wash them three times with deionized water; prepare a PVA solution with a solid-to-liquid ratio of 1 g: 6 mL. PVA is purchased from Aladdin Company with a molecular weight of 145,000. And stir (35r / min) for 120min; prepare cellulose nanocrystalline CNC, and prepare a CNC dispersion with a solid-to-liquid ratio of 1g: 50mL, and ultrasonicate for 30min; Mix the conductive monomer pyrrole solution, the mixing ratio is CNC: the mass ratio of the conductive monomer pyrrole is 1:1, and stir (30r / min) for 60min; prepare the initiator ammonium persulfate solution with a solid-liquid ratio of 1g:5mL, Among them, ammonium persulfate is purchased from Aladdin Company, AR, with a purity of ≥98%, and ultrasonicated for 30 minutes; according to the reaction ratio of CNC: the amount of initiator substance is 1:2, the initiator ammonium persulfate solution is added dropwise to the above mixture In the solution, use an initiator to initiate...

Embodiment 2

[0039] Cut 5 pieces of silk with a length of 20 cm and wash them three times with deionized water; prepare a PVA solution with a solid-to-liquid ratio of 1 g: 5 mL. PVA is purchased from Aladdin Company with a molecular weight of 145,000. and stirred (25r / min) for 100min; prepare CNC, and prepare a CNC dispersion with a solid-to-liquid ratio of 1g: 50mL, and ultrasonicate for 35min; The solution is mixed, the mixing ratio is CNC: the mass ratio of conductive monomer pyrrole is 1:1, and it is stirred (rotating speed is 25r / min) for 60min; the initiator ammonium persulfate solution with a solid-liquid ratio of 1g: 5mL is prepared, wherein ammonium persulfate Purchasing from Aladdin Company, AR, purity ≥ 98%, ultrasonication for 30 minutes; according to the reaction ratio of CNC: the ratio of the amount of initiator substance is 1:2, add the initiator solution dropwise to the above mixed solution, and use the initiator to initiate The polymerization reaction of the conductive mon...

Embodiment 3

[0041] Cut 10 pieces of silk with a length of 20 cm, and rinse them with deionized water for 5 times; prepare a PVA solution with a solid-to-liquid ratio of 1 g: 6.5 mL. PVA is purchased from Aladdin Company with a molecular weight of 145,000. Put it in a water bath at 80 ° C and heat it in a water bath , and stirred (25r / min) for 120min; prepared CNC, and prepared a CNC dispersion with a solid-to-liquid ratio of 1g: 50mL, ultrasonicated for 30min; Mix the aniline solution, the mixing ratio is CNC: the conductive monomer aniline mass ratio is 1:1, and stir (30r / min) for 65min; prepare an initiator potassium persulfate solution with a solid-liquid ratio of 1g:5mL, in which persulfate Potassium is procured from Aladdin Company with the molecular formula K 2 S 2 o 8 , the molecular weight is 270.32, ultrasound for 25min; according to the reaction ratio of CNC: initiator substance ratio of 1:2, the initiator solution is added dropwise to the above mixed solution, and the initiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com