Method for preparing gamma-linolenic acid-rich grease through sea squirt-associated Penicillium citrinum Asc2-4 fermentation

A technology of Penicillium citrinum and linolenic acid is applied in the field of preparing oil rich in γ-linolenic acid, can solve the problems of high cost, poor stability, complicated production process and the like, and achieves the effects of tenacious vitality, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

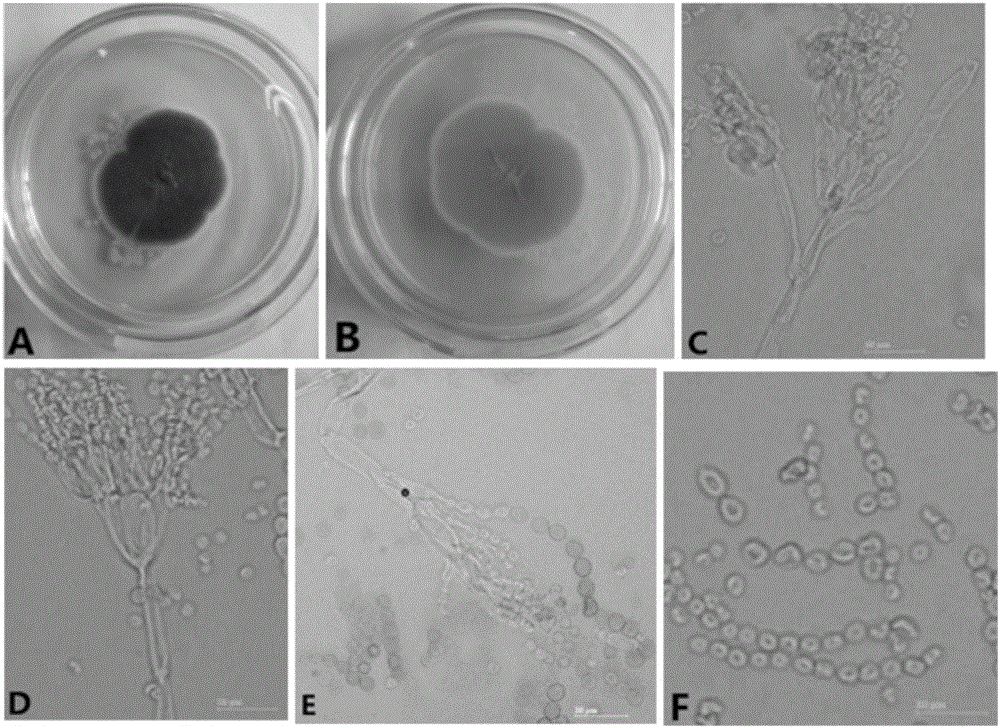

[0059] Example 1 Isolation and identification of ascidian symbiotic fungus Penicillium citrinum Asc2-4

[0060] 1. Strain isolation

[0061] (1) Sample: sea squirt, collected from quicksand shrimp pond in Leizhou City, Guangdong Province.

[0062] Take 10 g of sea squirt viscera, homogenize it with a homogenizer, put it into 90 mL of sterile sea water, shake and mix well. Then use sterile seawater to press 10 -2 ~10 -6 Dilute and spread on solid medium, culture at 28°C for 24-72 hours, and isolate single colonies.

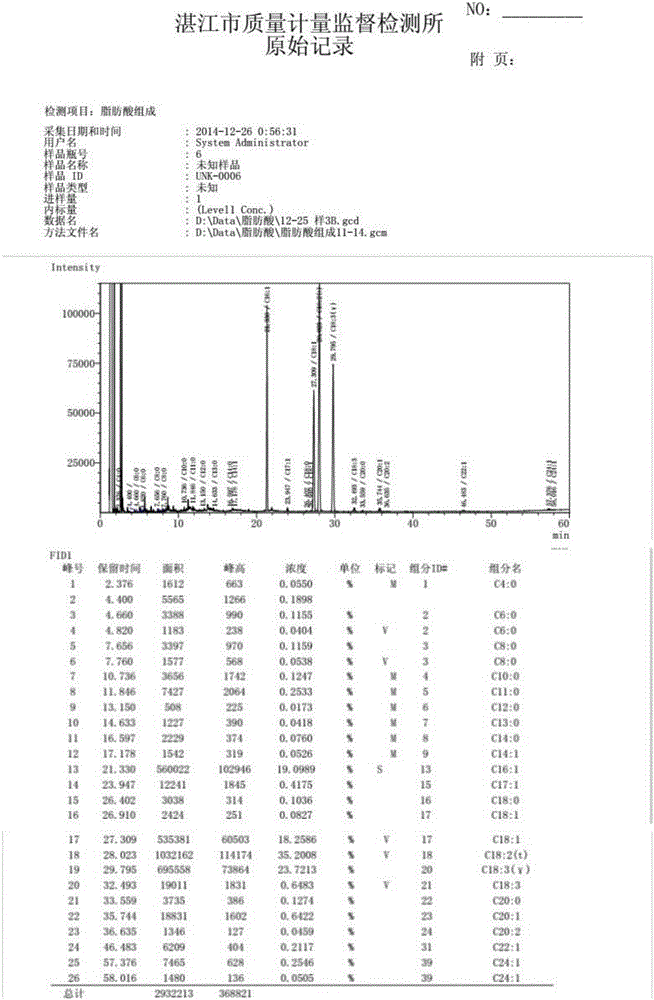

[0063] The above-mentioned single colony was further inoculated into a liquid seed medium, cultured on a shaker at 28°C for 72 hours, and the fat particles in the mycelia were observed under a microscope. Suction filter and dry the fermented mycelium, extract the oil in the mycelium by acid-heat method, measure the content of gamma-linolenic acid in the oil with a gas chromatograph, and select the strain with the highest gamma-linolenic acid content as the bact...

Embodiment 2

[0074] Example 2 Preparation of gamma-linolenic acid oil by fermentation of ascidian symbiotic fungus Penicillium citrinum Asc2-4

[0075] 1. A method for preparing gamma-linolenic acid oil by fermenting the ascidian symbiotic fungus Penicillium citrinum Asc2-4, comprising the following steps:

[0076] (1) Strain activation (solid strain culture):

[0077] Transfer the strains preserved in freeze-dried tubes or sand tubes to potato dextrose agar slant medium, and culture them at 25°C for 5 days to activate the strains;

[0078] (2) Seed liquid preparation (liquid strain culture):

[0079] The slant strains were made into spore suspension and inoculated in the seed medium for cultivation. The seed medium was potato dextrose medium, the inoculation amount was 3%, the pH was 5.5-6.5, the cultivation temperature was 28°C, and the cultivation time was 2 days ;

[0080] (3) Fermentation culture

[0081] 1) Fermentation medium preparation: Accurately weigh potatoes according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com