Relative humidity sensor device based on nano coaxial cavity structure and surface plasmon effect and manufacturing method thereof

A surface plasmon and relative humidity technology, applied in nanotechnology, instruments, scientific instruments, etc., can solve problems such as difficult to make nano-patterns, and achieve the effect of tight combination, strong applicability, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

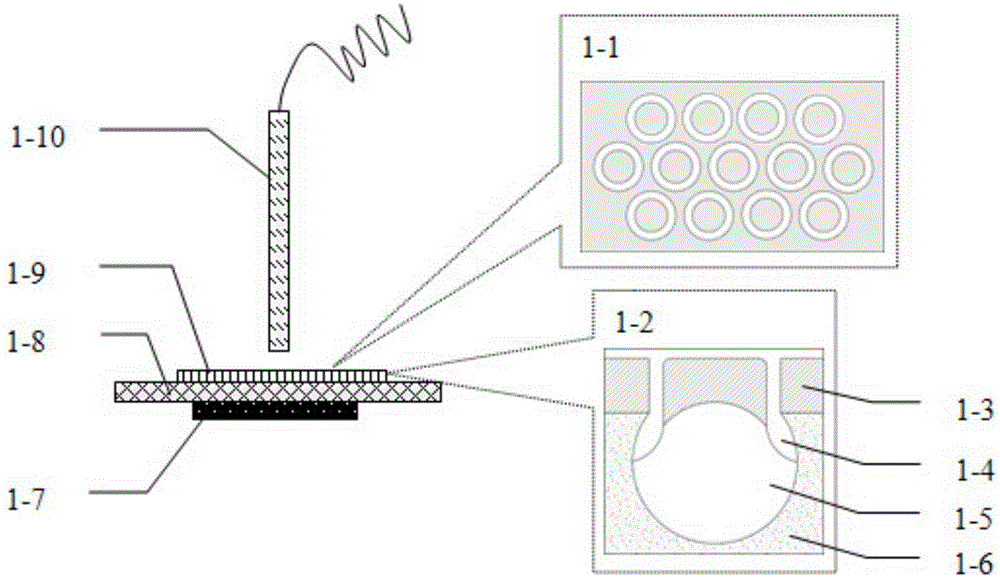

[0031] In this embodiment, the steps of preparing a coaxial cavity relative humidity sensor are as follows:

[0032] a) Take a glass slide 1-8 with a length of 7.5 cm and a width of 2.5 cm, and clean it with acetone (purity 99.7%), alcohol (purity 99.9%), deionized water (resistivity 18.2MΩ) ultrasonic (40W) for 10 Minutes, then blow dry with nitrogen gas (purity 99.7%); Then use plasma cleaner to treat slide glass for 5 minutes;

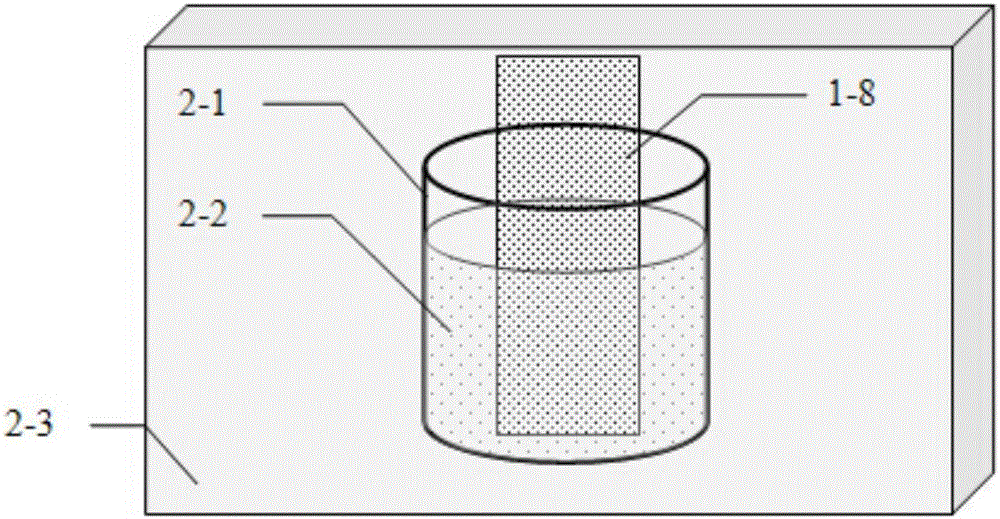

[0033] b) fixing the processed glass slides 1-8 with a custom-made container 2-1;

[0034] c) Configure SiO 2 Precursor solution of SiO 2 The mass of each substance in the precursor solution is: TEOS (98wt%)=1g, 0.1M / L HCl=1g, EtOH (100%)=1.5g, mix and stir for one hour for later use;

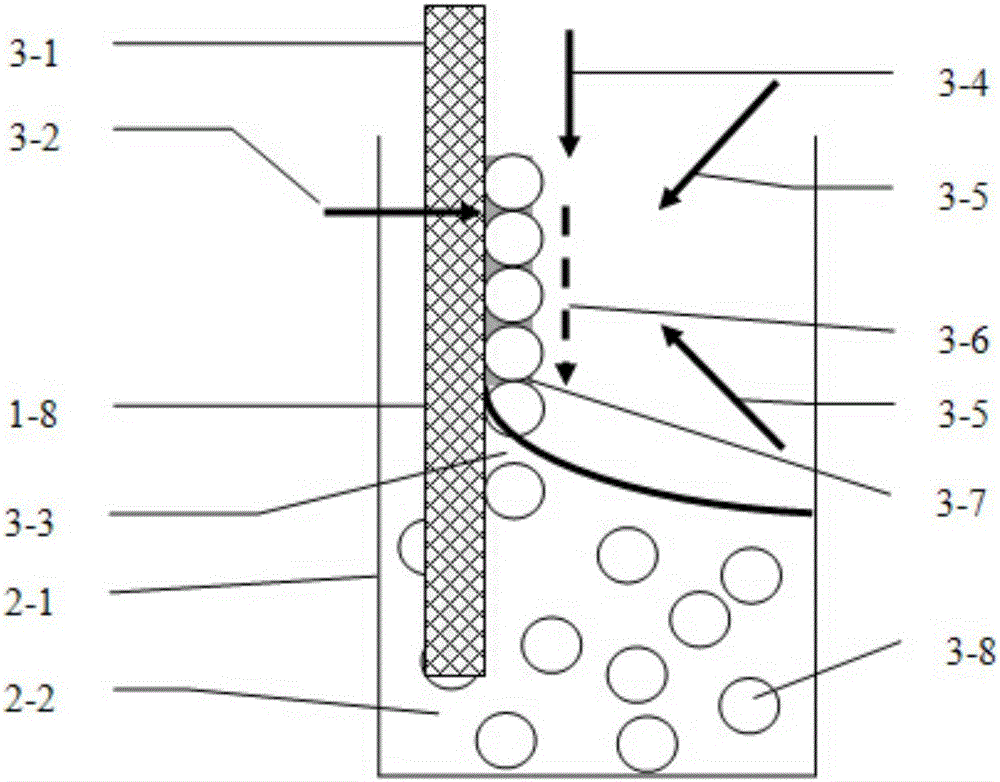

[0035] d) Configure polystyrene (PS) colloidal solution, 30ml, the diameter of colloidal microspheres 3-8 is 690nm, the deviation rate of microsphere diameter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com