Back contact solar cell and solar cell component

A solar cell and back contact technology, applied in the field of solar cells, can solve the problems of cost increase, incompatibility, breakdown, etc., and achieve the effect of simple structure, good reverse leakage current, and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

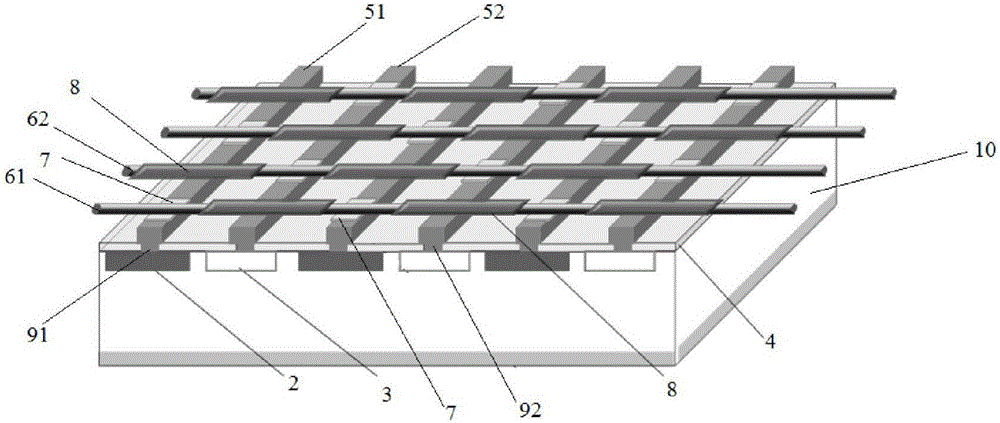

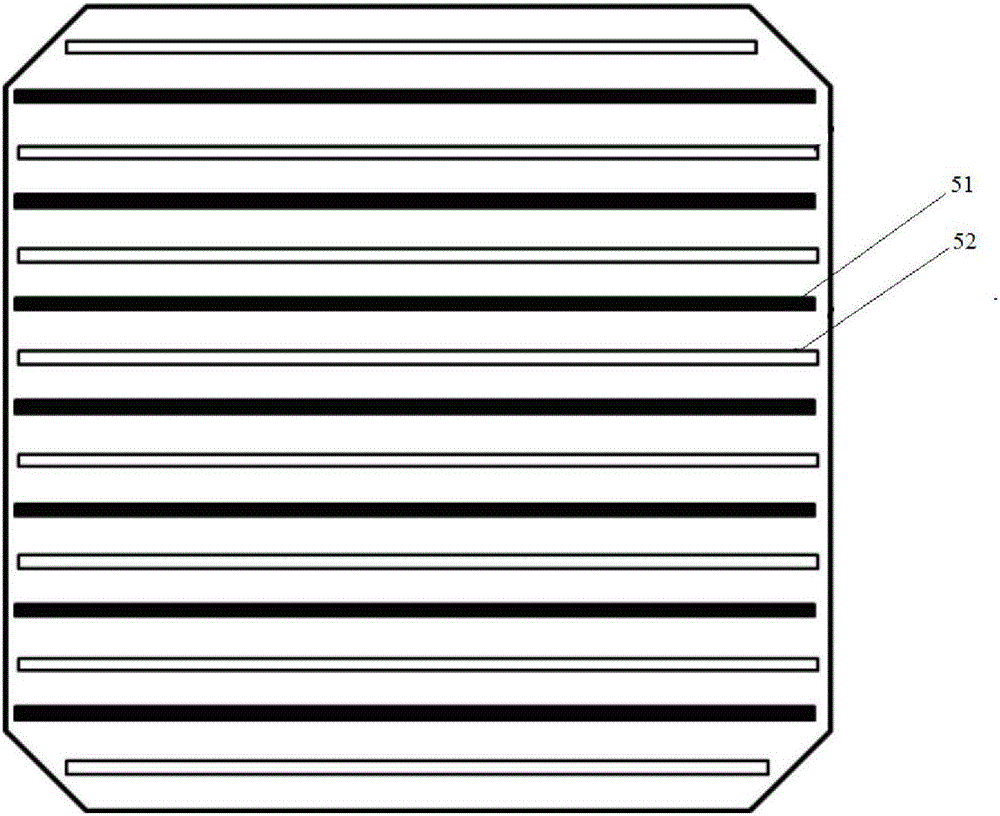

[0053] Such as figure 1 and image 3 As shown, a back-contact solar cell provided in this embodiment includes an n-type silicon substrate 10, a p+ doped region 2, an n+ doped region 3, a passivation antireflection layer 4, a positive electrode fine grid 51 and a negative electrode fine grid. The gate 52, the p+ doped region 2 and the n+ doped region 3 are alternately arranged and distributed on the back of the n-type silicon substrate 10, the passivation antireflection layer 4 is arranged on the p+ doped region 2 and the n+ doped region 3, and the positive electrode The fine grid 51 is arranged on the passivation anti-reflection layer 4 and connected to the p+ doped region 2, the negative electrode fine grid 52 is arranged on the passivation anti-reflection layer 4 and connected to the n+ doped region 3, and also includes a positive electrode The conductive wire 61 and the negative electrode conductive wire 62, the positive electrode conductive wire 61 is arranged on the posi...

Embodiment 2

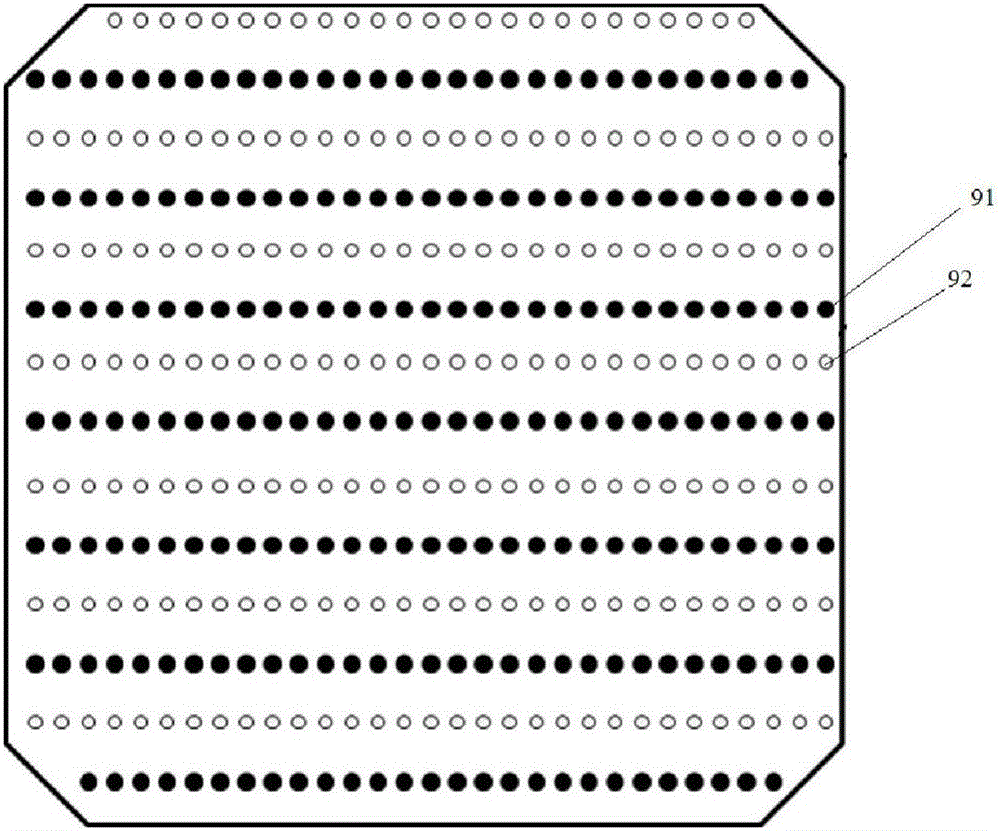

[0084] Such as figure 1 and image 3 As shown in , the back contact solar cell provided by this embodiment includes an n-type monocrystalline silicon substrate, an n+ front field and a front passivation layer arranged on the front side of the silicon substrate, a p+ doped region 2 and a front passivation layer arranged on the back side of the silicon substrate N+ doped regions 3, p+ doped regions 2 and n+ doped regions 3 are alternately arranged on the back of the silicon substrate, the passivation antireflection layer 4 is used for passivation of the back surface, and a positive electrode is provided on the p+ doped regions 2 A contact point 91, a negative electrode contact point 92 is provided on the n+ doped region 3, and a positive electrode fine grid 51 and a negative electrode fine grid 52 are also provided on the back side of the silicon substrate, respectively connecting the positive electrode contact point 91 and the negative electrode contact point 92.

[0085] Amo...

Embodiment 3

[0097] Different from Example 1, the preparation method of the back contact solar cell module is as follows:

[0098] (1) Select an n-type crystalline silicon wafer, and make p+ doped regions and n+ doped regions alternately arranged and distributed on the back side of the n-type crystalline silicon wafer;

[0099] (2) A passivation antireflection layer is provided on the p+ doped region and n+ doped region, a positive electrode contact point and a negative electrode contact point are arranged on the passivation antireflection layer, and a positive electrode fine grid is arranged on the positive electrode contact point Connecting them, setting the negative electrode fine grid on the negative electrode contact point and connecting them;

[0100] (3) The positive electrode conductive wire and the negative electrode conductive wire are arranged on the positive electrode contact fine grid and the negative electrode contact fine grid, wherein the positive electrode conductive wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com