Composite cathode material of sodium-ion battery and preparation method of composite cathode material

A composite cathode material, sodium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low electronic conductivity and ionic conductivity, affect structural stability and cycle performance, and it is difficult to obtain electrochemical performance. and other problems, to achieve the effect of improving ionic conductivity, good structural stability and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In order to obtain the above-mentioned positive electrode material, the present invention also provides a preparation method of a composite positive electrode material for a sodium ion battery, comprising:

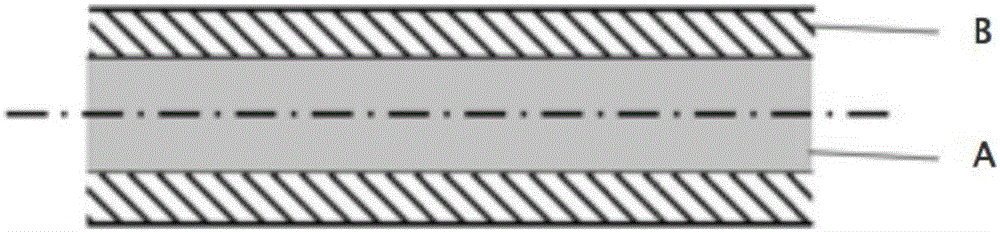

[0050]Molar ratio Na:Mn:P:F:spinning aid=2:1:1:1:(10 -5 ~10 -1 ) Sodium source compound, manganese source compound, phosphorus source compound, fluorine source compound and spinning aid are added to the solvent and mixed to obtain electrospinning solution A; in molar ratio Na:V:P:F:spinning aid= 3:2:2:3:(10 -5 ~10 -1 ) Add sodium source compound, vanadium source compound, phosphorus source compound, fluorine source compound and spinning aid to the solvent and mix to obtain electrospinning solution B; take electrospinning solution A as the inner axis, and use electrospinning solution A B is coaxial electrospinning on the outer axis to obtain a coaxial nanofiber precursor; the coaxial nanofiber precursor is heat-treated in an inert atmosphere, and the composite pos...

Embodiment 1

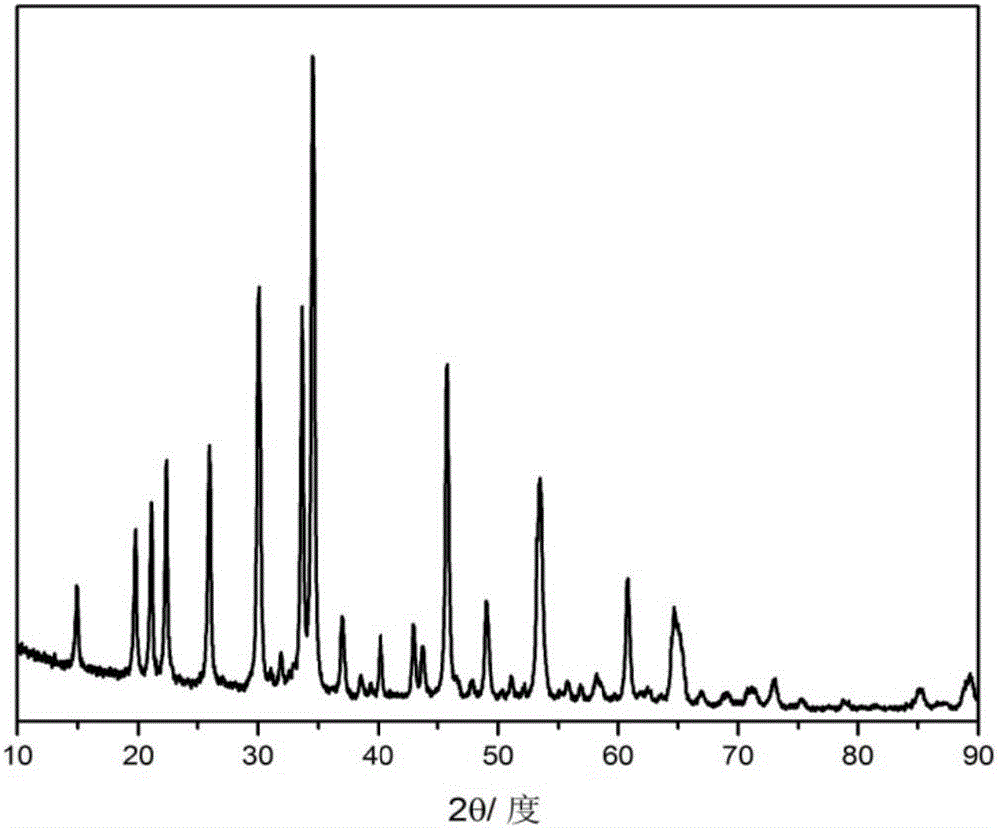

[0061] a. Prepare 0.97mol / L Na 2 PPML 4 F spinning solution 20mL: NaH 2 PO 4 , NaF, Mn(CH 3 COO) 2 4H 2 O according to the stoichiometric ratio, using dimethylformamide as a solvent, stirring at a temperature of 30°C until completely dissolved, adding 1.5g of polyvinylpyrrolidone with an average molecular weight of 1,300,000, and continuing to stir until a uniform spinning solution is formed;

[0062] b. Prepare 0.5mol / L Na 3 V 2 (PO 4 ) 2 f 3 Spinning solution 20mL: NaF, NH 4 VO 3 , NH 4 h 2 PO 4 Dosing according to the stoichiometric ratio, using dimethylformamide as a solvent, stirring at 30°C until completely dissolved, adding 1.5 g of polyvinylpyrrolidone with an average molecular weight of 1,300,000, and continuing to stir until a uniform spinning solution is formed.

[0063] c. Na 2 PPML 4 F spinning solution and Na 3 V 2 (PO 4 ) 2 f 3 The spinning solution was pumped into 5mL syringe pumps respectively, a coaxial spinning needle was installed, the...

Embodiment 2

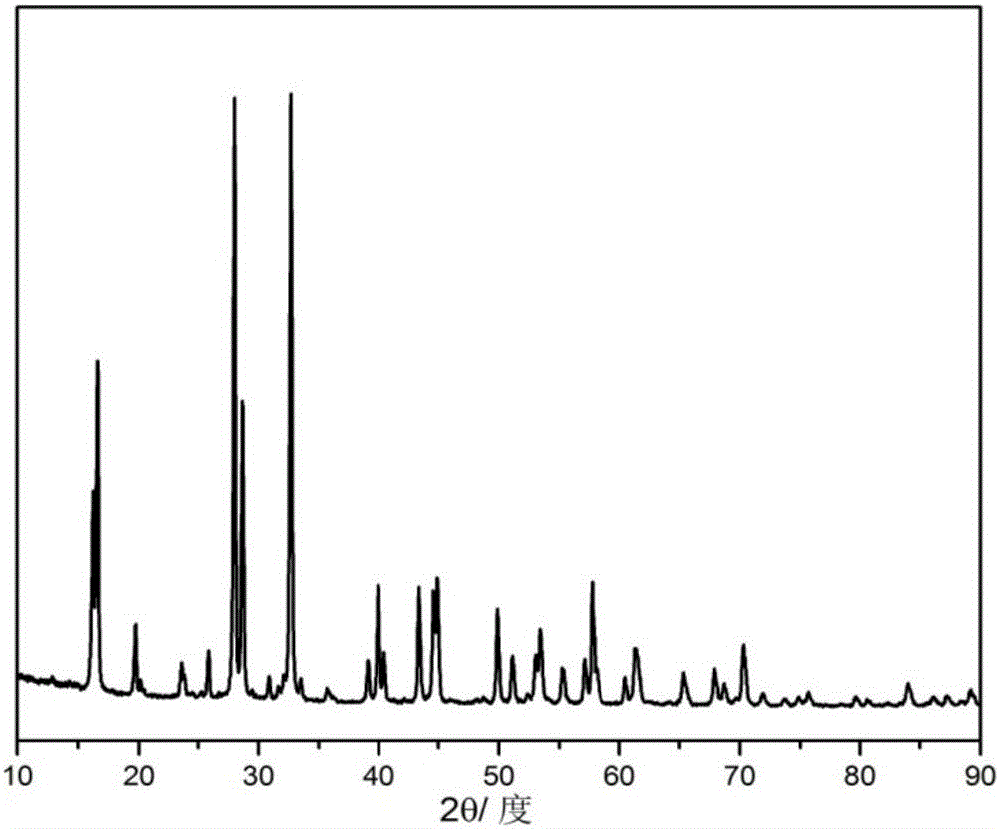

[0066] a. Prepare 0.97mol / L Na 2 PPML 4 F spinning solution 20mL: NaH 2 PO 4 , NaF, Mn(CH 3 COO) 2 4H 2 O according to the stoichiometric ratio, using dimethylformamide as a solvent, stirring at a temperature of 30°C until completely dissolved, adding 1.5g of polyvinylpyrrolidone with an average molecular weight of 1,300,000, and continuing to stir until a uniform spinning solution is formed;

[0067] b. Prepare 0.5mol / L Na 3 V 2 (PO 4 ) 2 f 3 Spinning solution 20mL: NaF, NH 4 VO 3 , NH 4 h 2 PO 4 Dosing according to the stoichiometric ratio, using dimethylformamide as a solvent, stirring at 30°C until completely dissolved, adding 1.5 g of polyvinylpyrrolidone with an average molecular weight of 1,300,000, and continuing to stir until a uniform spinning solution is formed.

[0068] c. Na 2 PPML 4 F spinning solution and Na 3 V 2 (PO 4 ) 2 f 3 The spinning solution was extracted into 5mL syringes respectively, and a coaxial spinning needle was installed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com