Lithium vanadium phosphate cathode material as well as preparation method and application thereof

A lithium vanadium phosphate and positive electrode material technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problem of reducing the content of active materials, affecting active materials and current collectors, and reducing the characteristics of lithium vanadium phosphate nanofibers and nanorods and other issues, to achieve large specific area, improve electronic conductivity and lithium ion diffusion ability, improve high rate performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

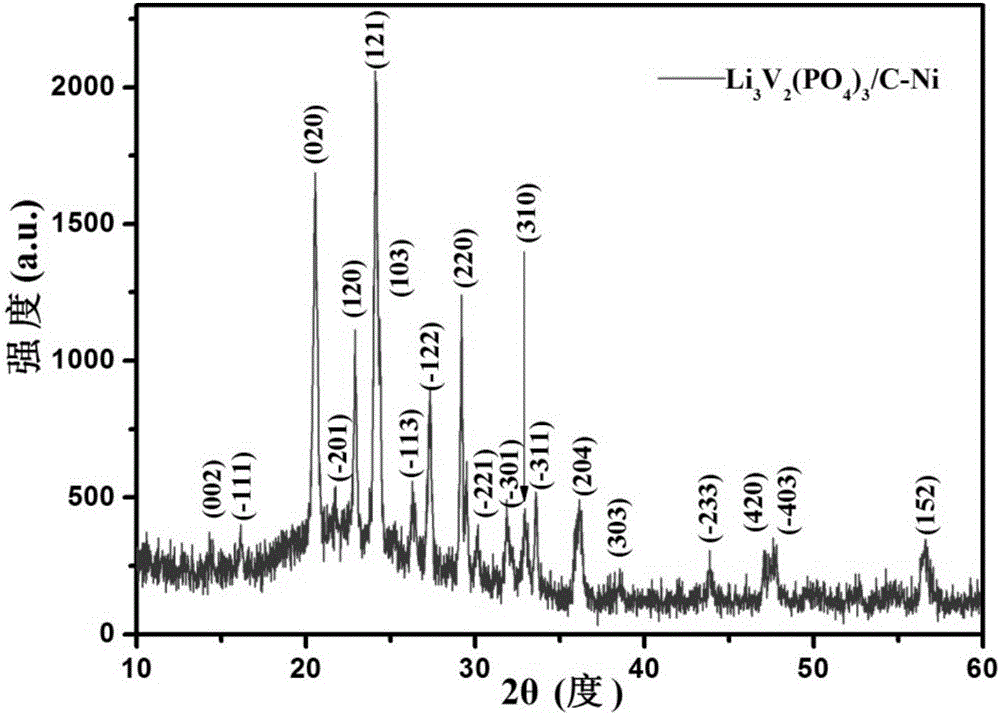

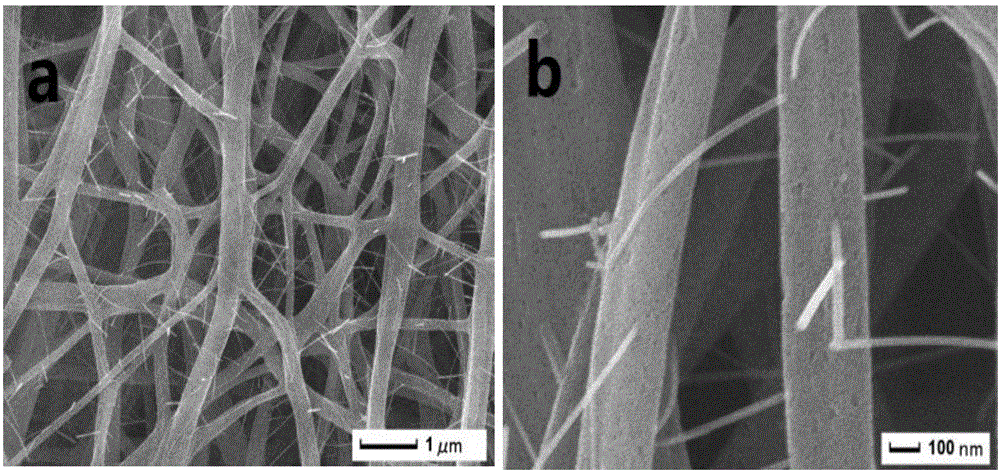

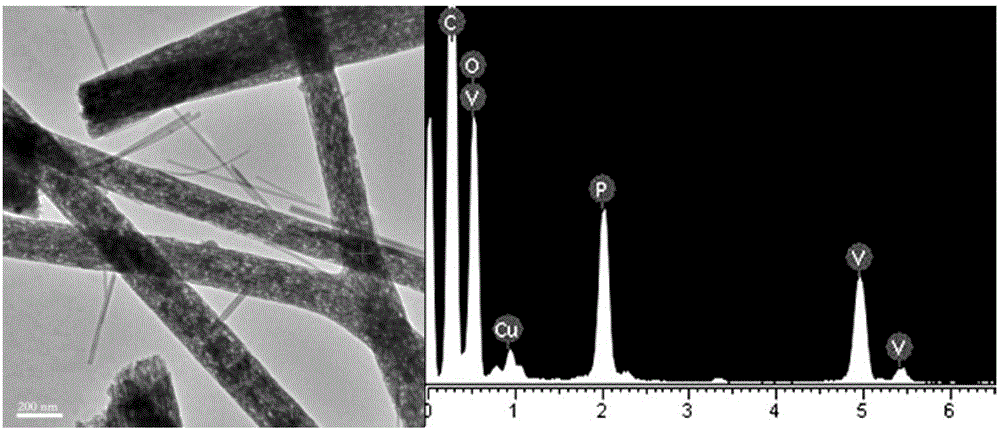

[0039] A lithium vanadium phosphate positive electrode material of the present invention, which has a three-dimensional network structure, and is mainly composed of lithium vanadium phosphate single crystal nanowires and lithium vanadium phosphate nanofibers intersecting, and the lithium vanadium phosphate nanowires are grafted and grown on the surface of the lithium vanadium phosphate nanofibers; The thickness of the lithium vanadium phosphate positive electrode material is 200um, and the porosity is 80%; the diameter of the lithium vanadium phosphate single crystal nanowire is 20nm, and the length is 0.5-1.2um; the lithium vanadium phosphate nanofiber is made of lithium vanadium phosphate nanoparticles embedded in activated carbon The porous composite fiber formed in the substrate has a diameter of 130-180 nm in the lithium vanadium phosphate nanofiber, and the mass content of carbon in the lithium vanadium phosphate nanofiber is 22%.

[0040] The preparation method of the li...

Embodiment 2

[0050] A lithium vanadium phosphate positive electrode material of the present invention has a three-dimensional network structure, and is mainly composed of lithium vanadium phosphate single crystal nanowires and lithium vanadium phosphate nanofibers intersecting, and the lithium vanadium phosphate nanowires are mainly grafted and grown on the surface of lithium vanadium phosphate nanofibers The thickness of the lithium vanadium phosphate positive electrode material is 20um, and the porosity is 60%. The diameter of the lithium vanadium phosphate single crystal nanowire is 30nm, and the length is 100-500nm; The porous composite fiber formed in the substrate has a diameter of 230-280 nm in the lithium vanadium phosphate nanofiber, and the mass content of carbon in the lithium vanadium phosphate nanofiber is 15%.

[0051] The preparation method of the lithium vanadium phosphate cathode material of the present embodiment comprises the following steps:

[0052] (1) Get 0.5mL of ni...

Embodiment 3

[0061] A lithium vanadium phosphate positive electrode material of the present invention has a three-dimensional network structure, and is mainly composed of lithium vanadium phosphate single crystal nanowires and lithium vanadium phosphate nanofibers intersecting, and the lithium vanadium phosphate nanowires are mainly grafted and grown on the surface of lithium vanadium phosphate nanofibers The thickness of the lithium vanadium phosphate positive electrode material is 87um, and the porosity is 80%. The diameter of the lithium vanadium phosphate single crystal nanowire is 10nm, and the length is 6-10um; The porous composite fiber formed in the substrate has a diameter of 300-360 nm in the lithium vanadium phosphate nanofiber, and the mass content of carbon in the lithium vanadium phosphate nanofiber is 30%.

[0062] The preparation method of the lithium vanadium phosphate cathode material of the present embodiment comprises the following steps:

[0063] (1) Get 0.5mL of nitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com