A kind of yeast microcapsule of crocin and preparation method thereof

A crocin and microcapsule technology, applied in the field of medicine, can solve the problems of expensive equipment, residual chemical reagents, etc., and achieve the effects of convenient operation, stable biological activity of the medicine, and easy preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

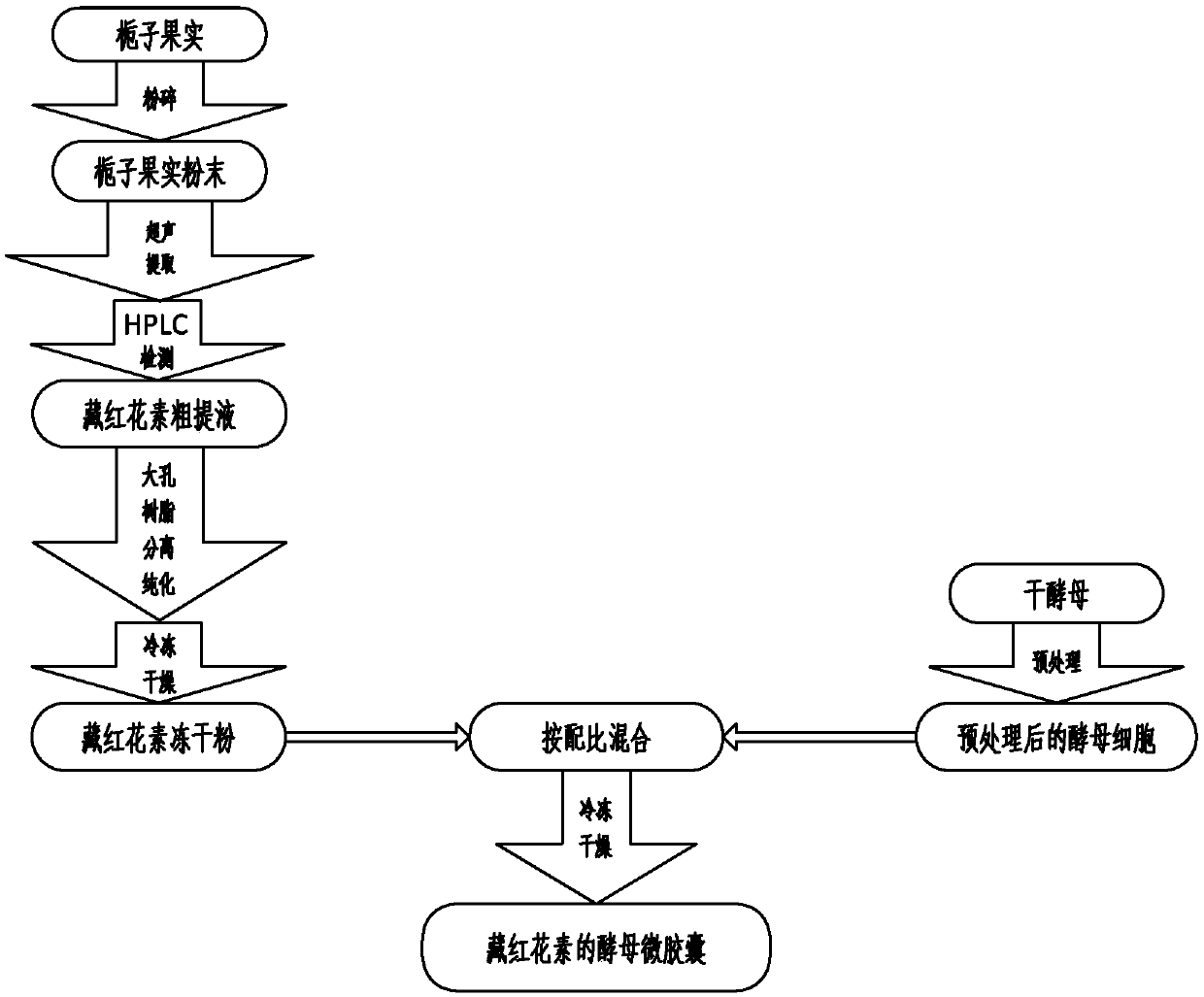

Method used

Image

Examples

Embodiment 1

[0034] a) Take 2000 g of gardenia fruit, pulverize them with a traditional Chinese medicine pulverizer, pass through a 40-mesh sieve, add 12 times the amount of 50% ethanol, extract 3 times with frequency 40 kHz, power 300 W ultrasonically at room temperature, each time for 30 min, filter, and combine the filtrates;

[0035] b) The combined filtrate of step a) is purified with D-101 macroporous resin. After the macroporous resin is pretreated, the column is packed at an adsorption flow rate of 2BV / h. After the adsorption is saturated, use 80% ethanol containing 0.1mol / L HCl as Eluent, elute 4BV at 50°C and desorption flow rate of 2BV / h; the eluent is suction filtered, rotary evaporated to remove ethanol, concentrated to obtain extract, freeze-dried to obtain saffron freeze-dried powder, the yield of saffron is 1.38%, and the purity is 85.34%;

[0036] c) Take a certain amount of Angel dry yeast, add 20 times the amount of 5% NaCl solution, shake in a water bath at 54°C for 5 h...

Embodiment 2

[0039] a) Take 2000 g of gardenia fruit, pulverize them with a traditional Chinese medicine pulverizer, pass through a 40-mesh sieve, add 12 times the amount of 50% ethanol, extract 3 times with frequency 40 kHz, power 300 W ultrasonically at room temperature, each time for 30 min, filter, and combine the filtrates;

[0040] b) The combined filtrate of step a) is purified with D-101 macroporous resin. After the macroporous resin is pretreated, the column is packed at an adsorption flow rate of 2BV / h. After the adsorption is saturated, use 50% ethanol containing 0.1mol / L HCl as Eluent, elute 4BV at 50°C and desorption flow rate of 2BV / h; the eluent is suction filtered, rotary evaporated to remove ethanol, concentrated to obtain extract, freeze-dried to obtain saffron freeze-dried powder, the yield of saffron is 1.21%, and the purity is 85.34%;

[0041] c) Take a certain amount of Angel dry yeast, add 20 times the amount of 5% NaCl solution, shake in a water bath at 54°C for 8 h...

Embodiment 3

[0044] a) Take 2000 g of gardenia fruit, pulverize them with a traditional Chinese medicine pulverizer, pass through a 40-mesh sieve, add 20 times the amount of 50% ethanol, use frequency 40 kHz, power 300 W ultrasonic extraction at room temperature for 3 times, each time for 30 min, filter, and combine the filtrates;

[0045] b) The combined filtrate of step a) is purified with D-101 macroporous resin. After the macroporous resin is pretreated, the column is packed at an adsorption flow rate of 2BV / h. After the adsorption is saturated, use 50% ethanol containing 0.1mol / L HCl as Eluent, elute 4BV at 50°C and desorption flow rate of 2BV / h; the eluent is suction filtered, rotary evaporated to remove ethanol, concentrated to obtain extract, freeze-dried to obtain saffron freeze-dried powder, the yield of saffron is 1.83%, and the purity is 83.21%;

[0046] c) Take a certain amount of Angel dry yeast, add 20 times the amount of 5% NaCl solution, shake in a water bath at 54°C for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com