Method for preparing Fe3O4/SiO2/N-TiO2 magnetic visible-light-induced photocatalyst with nitric acid being nitrogen source

A visible light and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low catalytic activity of visible light, and achieve the effect of strong magnetism and easy magnetic separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

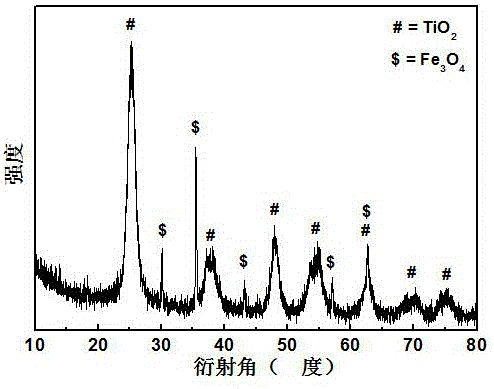

Image

Examples

Embodiment 1

[0025] 1. Weigh 900mg of Fe 3 o 4 Add 720mL of ethanol and 180mL of water to the mixed solution, add 9mL of ammonia water, after 30 minutes of ultrasonication, slowly add 3mL of tetraethyl orthosilicate dropwise under the strong stirring of a dynamic stirrer, stir at room temperature for 6 hours and then under the action of an external magnetic field The sample was magnetically separated, and the separated solid phase was centrifuged and washed with distilled water and ethanol, and dried in a vacuum oven at 80°C for 6 hours to obtain Fe with a core-shell structure. 3 o 4 / SiO 2 Binary nanocomposites;

[0026] 2. Weigh 37mL of absolute ethanol and add it to the PTFE lining, add 50mg of Fe 3 o 4 / SiO 2 Nanocomposite, sonicate for 10 minutes, slowly add 2 mL of n-tetrabutyl titanate dropwise, then add 1 mL of concentrated nitric acid and stir for 20 minutes. Put the polytetrafluoroethylene liner into a stainless steel high-pressure reaction kettle, seal it, place it in an ...

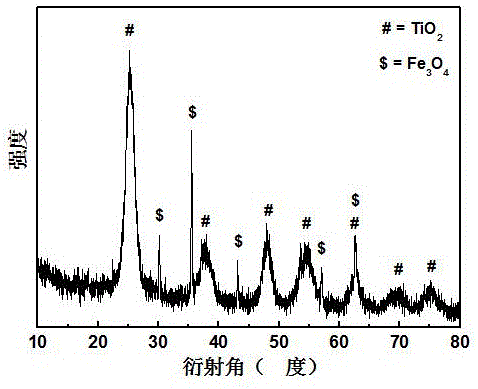

Embodiment 2

[0030] 1. Weigh 900mg of Fe 3 o 4 Add 720mL of ethanol and 180mL of water to the mixed solution, add 9mL of ammonia water, after 30 minutes of ultrasonication, slowly add 3mL of tetraethyl orthosilicate dropwise under the strong stirring of a dynamic stirrer, stir at room temperature for 6 hours and then under the action of an external magnetic field The sample was magnetically separated, washed by centrifugation with distilled water and ethanol, and dried in a vacuum oven at 80°C for 6 hours to obtain Fe with a core-shell structure. 3 o 4 / SiO 2 Binary nanocomposites;

[0031] 2. Weigh 36mL of absolute ethanol and add it to the PTFE lining, add 50mg of Fe 3 o 4 / SiO 2 Nanocomposite, sonicate for 10 minutes, slowly add 2 mL of n-tetrabutyl titanate dropwise, then add 2 mL of concentrated nitric acid and stir for 20 minutes. Put the polytetrafluoroethylene liner into a stainless steel high-pressure reaction kettle, seal it, heat it in an electric oven at 185°C for 15 hou...

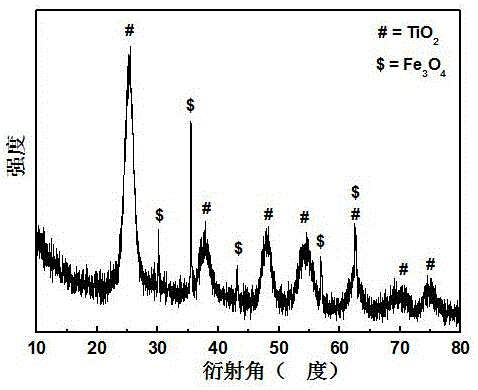

Embodiment 3

[0035] 1. Weigh 900mg of Fe 3 o 4 Add 720mL of ethanol and 180mL of water to the mixed solution, add 9mL of ammonia water, after 30 minutes of ultrasonication, slowly add 3mL of tetraethyl orthosilicate dropwise under the strong stirring of a dynamic stirrer, stir at room temperature for 6 hours and then under the action of an external magnetic field The sample was magnetically separated, washed by centrifugation with distilled water and ethanol, and dried in a vacuum oven at 80°C for 6 hours to obtain Fe with a core-shell structure. 3 o 4 / SiO 2 Binary nanocomposites;

[0036] 2. Weigh 35mL of absolute ethanol and add it to the PTFE lining, add 50mg of Fe 3 o 4 / SiO 2 The nanocomposite was ultrasonicated for 10 minutes, 2 ml of n-tetrabutyl titanate was slowly added dropwise, and then 3 ml of concentrated nitric acid was added and stirred for 20 minutes. Put the polytetrafluoroethylene liner into a stainless steel high-pressure reaction kettle, seal it, heat it in an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com