Supported metal-organic framework composite material, and preparation method and application thereof

A metal-organic framework and composite material technology, which is applied to the preparation technology of crystalline materials and their supported composite materials and the field of catalysis applications, can solve the problems of reducing the catalytic effect and agglomeration, and achieves the effects of good dispersibility and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

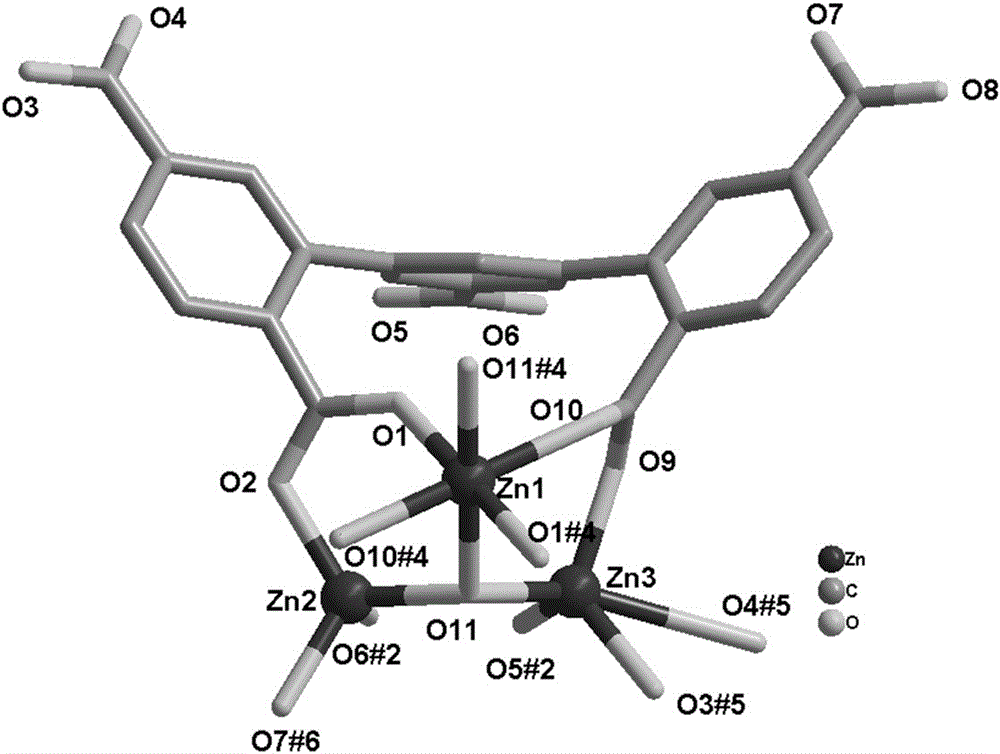

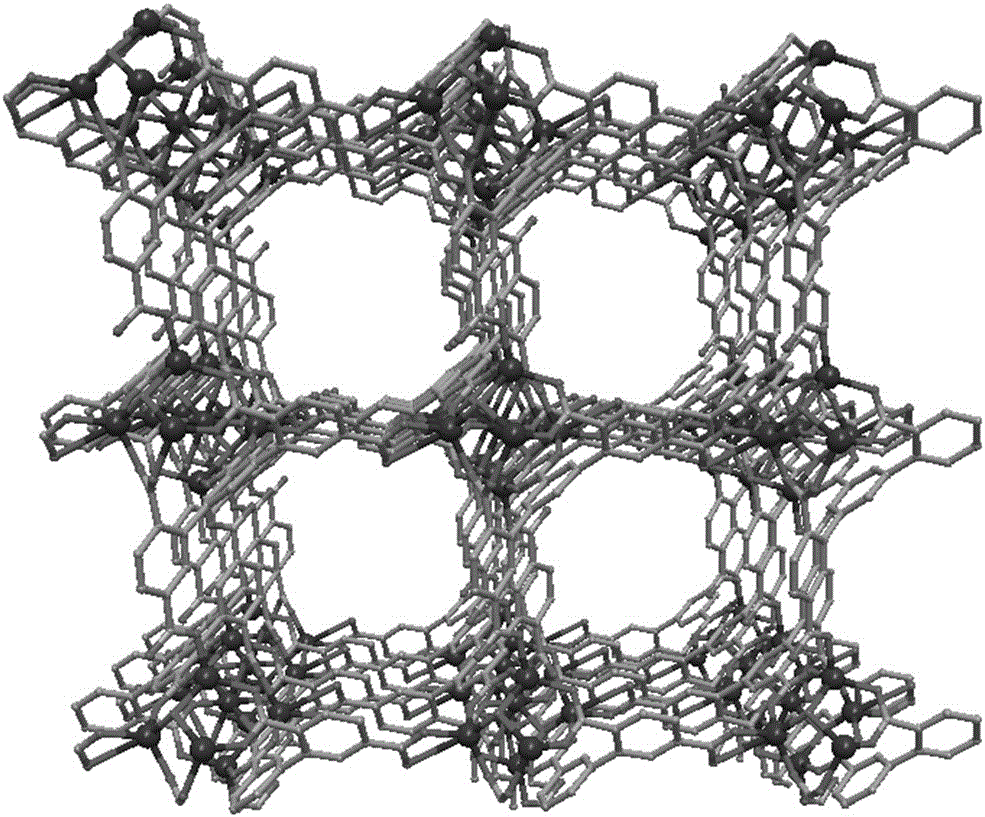

[0026] Accurately weigh 0.05mmol 3,5-di(2,5-dicarboxyphenyl)benzoic acid, 0.05mmol zinc nitrate, 5ml DMA, 5ml H 2 O, put into a stainless steel reaction kettle with Teflon lining, react at a constant temperature of 140°C for 72h, and then cool down to room temperature at a constant rate of 2-3°C / h to obtain a colorless and transparent bulk porous crystalline metal-organic framework material . Namely Zn-MOF. (The general chemical formula is: {[Zn 5 (ddcba) 2 ]} n , n is positive infinity, and n only represents the structural characteristics of crystalline materials constructed by the repeated appearance of the smallest unit, which is a general formula).

Embodiment 2

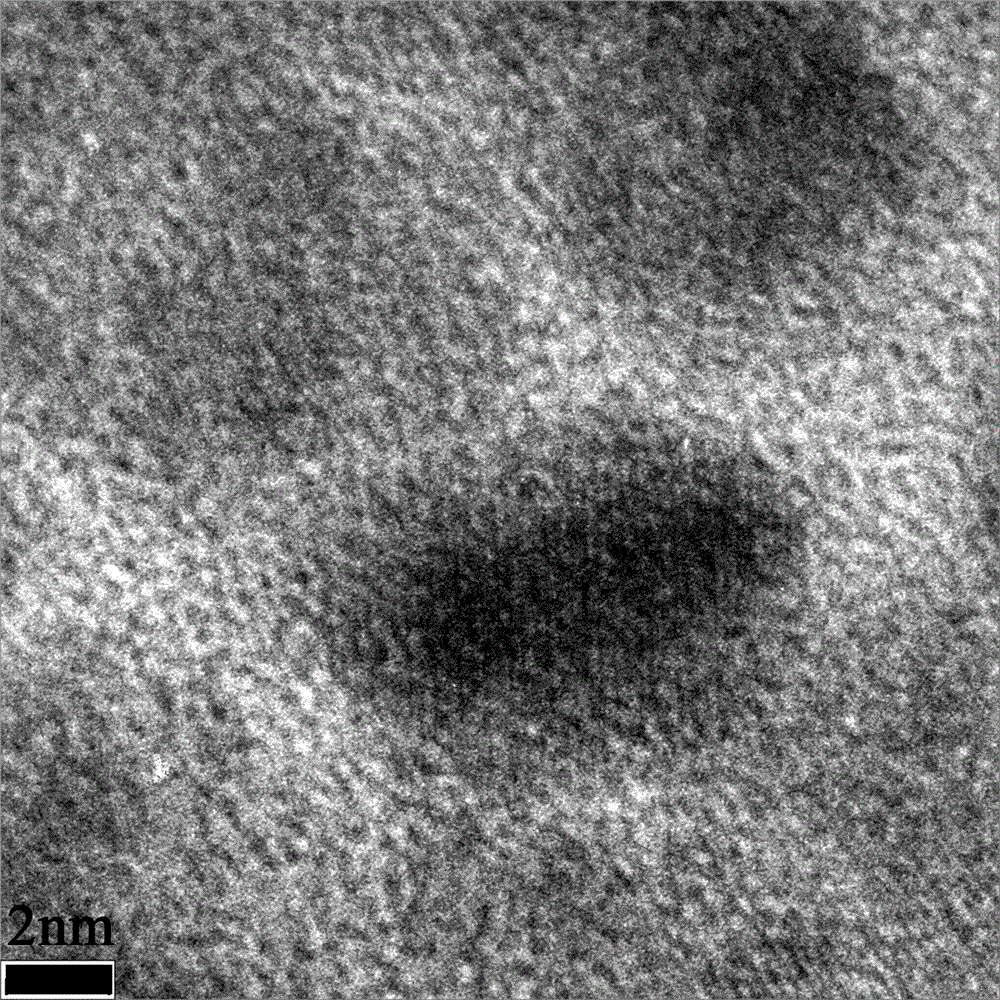

[0028] 1) The porous crystalline metal-organic framework material obtained in Example 1 is used as a carrier after being replaced by a solvent to remove guest molecules (guest molecules mainly refer to water molecules and DMA molecules introduced in the synthesis of crystalline materials. Since the material has a pore structure, Both will have certain residues in the channel). The replacement method is: soak the crystalline material sample in ethanol solution for 48 hours, replace the ethanol solution every 24 hours, and then dry it in vacuum at 80°C for 6 hours. Subsequently, 100 mg of the displaced crystalline material was added to 15 ml of deionized water, and then 0.5 ml of a 10 mg / L silver nitrate solution was added, and the above mixed system was shaken for 24 hours.

[0029] 2) Transfer the above mixed system to the quartz test tube of the photochemical reactor, under the condition of stirring, use a mercury lamp with a power of 300W to irradiate with ultraviolet light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com