Anatase titanium dioxide nano-material with exposed controllable high-activity crystal faces and preparation method and application thereof

An anatase-type titanium dioxide and nano-material technology, applied in the field of nano-materials, can solve the problems of cumbersome steps, high recombination rate of photogenerated electron-hole pairs, low sunlight utilization rate, etc., achieve good antibacterial effect, high efficiency visible light catalytic inhibition The effect of bacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing an anatase titanium dioxide nanomaterial exposing a controllable highly active crystal face, specifically comprising the following steps:

[0033] (1) Weigh water and ammonium fluoride at a molar ratio of 1 to 10:5 to prepare solution A;

[0034] (2) Add titanium tetrachloride solution to solution A, stir at a speed of 800r / min for 0.5h, and prepare solution B;

[0035] (3) Put the solution B into a polytetrafluoroethylene reactor, and cool it to room temperature after reacting for 8-24 hours in a drying oven at 170-210°C;

[0036] 4) Pour off the supernatant in the hydrothermal reaction kettle, and wash the solid-liquid mixture at the bottom in a 10000r / pm centrifuge with water for three times;

[0037] 5) The precipitate obtained in step 4) is washed several times with absolute ethanol and deionized water successively;

[0038] 6) drying the washed precipitate obtained in step 5) at 60° C. for 6 hours to prepare anatase titanium dioxide nanoma...

Embodiment 1

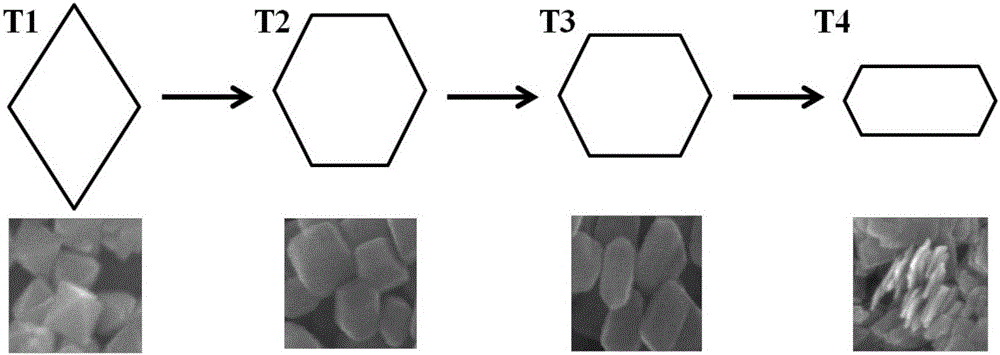

[0040] Weigh 1.7g of ammonium fluoride and dissolve it in 10mL of water. After stirring at a constant speed to dissolve, add 2mL of titanium tetrachloride, continue to stir at a speed of 800r / min for 30min, transfer to a polytetrafluoroethylene-lined autoclave, and react at 180°C for 12h. After cooling down to room temperature, the reaction solution was centrifuged and washed with water three times in a 10000r / pm centrifuge, and then the obtained precipitate was washed with absolute ethanol and deionized water for more than three times, and dried at 60°C for 6 hours to obtain The anatase titanium dioxide nanomaterial (marked as T1) with controllable and highly active crystal faces exposed, the ratio of {001} crystal face and {101} crystal face of the material is 1%, and the size is 50-70nm.

Embodiment 2

[0042] Weigh 1.2g of ammonium fluoride and dissolve it in 10mL of water. After stirring at a constant speed to dissolve, add 2mL of titanium tetrachloride, continue to stir at a speed of 800r / min for 30min, transfer to a polytetrafluoroethylene-lined autoclave, and react at 210°C for 8h. After cooling down to room temperature, the reaction solution was centrifuged and washed with water three times in a 10000r / pm centrifuge, and then the obtained precipitate was washed with absolute ethanol and deionized water for more than three times, and dried at 60°C for 6 hours to obtain The anatase titanium dioxide nanomaterial (marked as T2) with controllable and highly active crystal faces exposed, the ratio of {001} crystal face and {101} crystal face of the material is 10%, and the size is 50-70nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com