A treatment method for resource utilization of inorganic salts in ammonia desulfurization waste liquid

A technology for ammonia desulfurization and desulfurization waste liquid, which is applied in chemical instruments and methods, oxidized water/sewage treatment, neutralized water/sewage treatment, etc., and can solve the problems of high price, high operation and maintenance costs, and ineffective ammonium sulfate. Deal with and other issues to achieve the effect of improving economic benefits and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

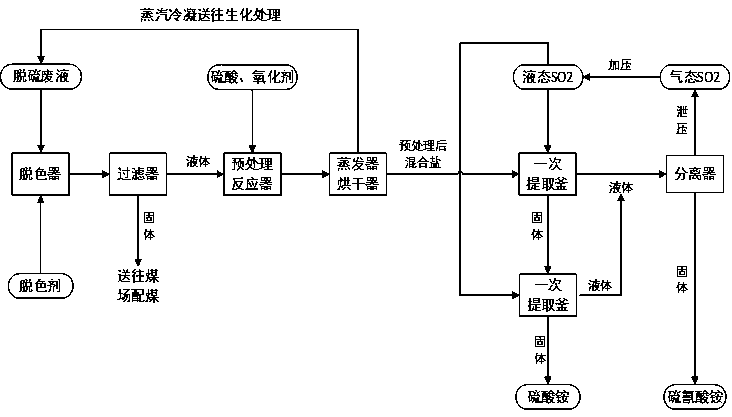

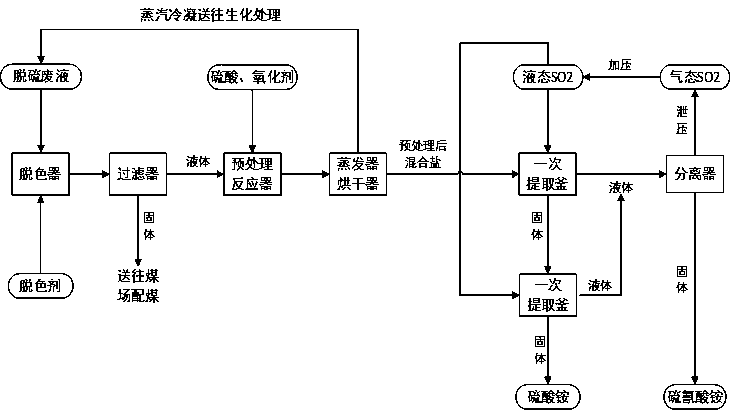

Image

Examples

Embodiment 1

[0039] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, suspended sulfur, PDS, free ammonia, see Table 1 for details.

[0040] Table 1 Main composition of desulfurization waste liquid

[0041] Ammonium thiosulfate g·L -1

Ammonium thiocyanate g·L -1

Suspended sulfur g·L -1

PDS(ppm) Free ammonia g·L -1

pH 90.32 140.68 0.87 49.24 5.71 8.22

[0042] In the first step, 5 g of activated carbon was added to 500 mL of ammonia desulfurization waste liquid, stirred at 20 °C for 3 h, and then filtered to obtain decolorized desulfurization waste liquid.

[0043] In the second step, the above decolorized desulfurization waste liquid and...

Embodiment 2

[0048] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, suspended sulfur, PDS, free ammonia, see Table 2 for details.

[0049] Table 2 Main composition of desulfurization waste liquid

[0050] Ammonium thiosulfate g·L -1

Ammonium thiocyanate g·L -1

Suspended sulfur g·L -1

PDS(ppm) Free ammonia g·L -1

pH 96.72 151.80 0.88 43.66 5.58 8.12

[0051] In the first step, 25 g of activated carbon was added to 500 mL of ammonia desulfurization waste liquid, stirred at 50 °C for 0.5 h, and then filtered to obtain decolorized desulfurization waste liquid.

[0052] In the second step, the desulfurization waste liquid after decolorizati...

Embodiment 3

[0057] The coking desulfurization waste liquid used in this example is the desulfurization waste liquid produced by removing hydrogen sulfide from the coking gas of the coking plant by using the HPF method. Take 500 mL of the desulfurization waste liquid. The main components of the desulfurization waste liquid are ammonium thiocyanate, thiosulfuric acid Ammonium, suspended sulfur, PDS, free ammonia, see Table 3 for details.

[0058] Table 3 Main composition of desulfurization waste liquid

[0059] Ammonium thiosulfate g·L -1

Ammonium thiocyanate g·L -1

Suspended sulfur g·L -1

PDS(ppm) Free ammonia g·L -1

pH 58.72 164.68 0.69 40.65 5.03 8.16

[0060] In the first step, 15 g of activated carbon was added to 500 mL of ammonia desulfurization waste liquid, stirred at 80 °C for 1.5 h, and then filtered to obtain decolorized desulfurization waste liquid.

[0061] In the second step, the above decolorized desulfurization waste liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com