Synthesis method of furfuryl alcohol, and porous nanometer silicon carbide supported platinum catalyst

A nano-silicon carbide and synthesis method technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve rare problems and achieve the goals of reducing energy consumption, high conversion rate, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of Porous Nano-Silicon Carbide Supported Platinum Catalyst 3Pt / SiC

[0049] (a), drop the aqueous solution of chloroplatinic acid in the porous nano-silicon carbide SiC carrier, the weight ratio of its metal platinum and the carrier is 1:32, after ultrasonic, stirring 5 hours, the solvent is naturally dried, then in an oven for 80 Dry at 100°C for 14 hours to obtain a porous nano-silicon carbide supported platinum catalyst precursor;

[0050] (b) Calcining the above catalyst precursor at 200° C. for 4 hours under nitrogen atmosphere.

[0051] (c) Reducing the calcined catalyst precursor at 500° C. for 3 hours in an atmosphere of 99.999% high-purity hydrogen to obtain a porous nano-silicon carbide-supported platinum catalyst 3Pt / SiC.

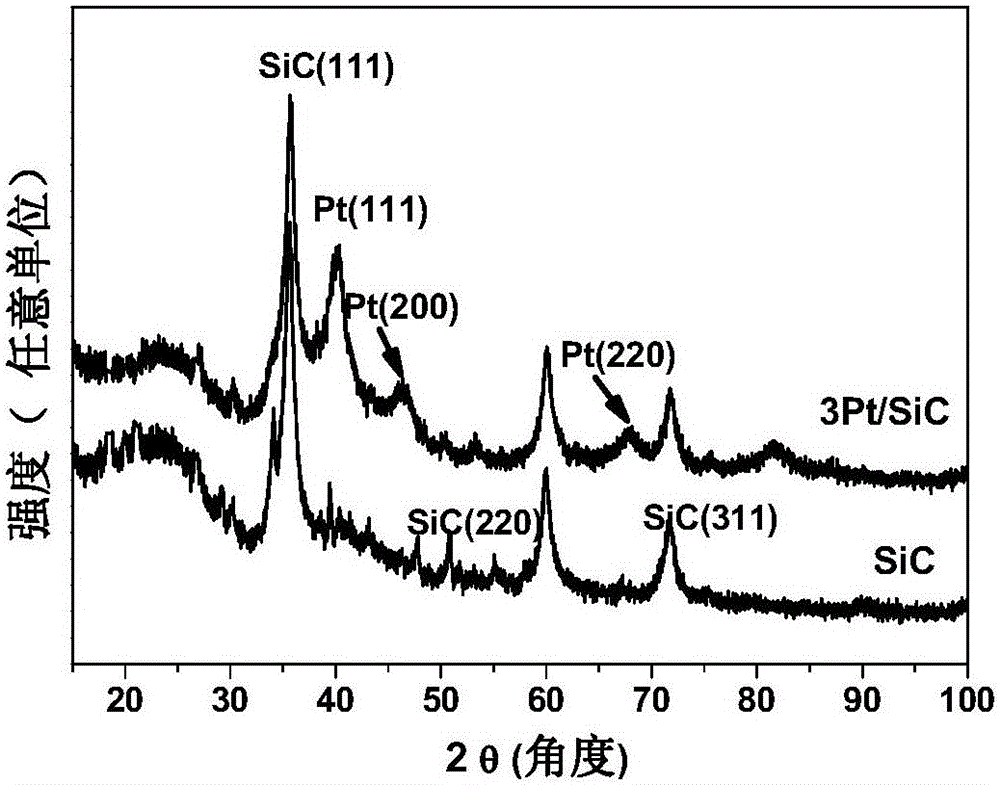

[0052] The porous nano-silicon carbide material and its large-angle X-ray diffraction as a carrier-supported platinum catalyst 3Pt / SiC are shown in figure 1 ,From figure 1 It can be found that the 2θ is at 35.6°, 6...

Embodiment 2

[0053] Example 2 Preparation of Porous Nano-Silicon Carbide Supported Platinum Catalyst Pt / SiC

[0054] The operating steps and conditions are the same as in Example 1, except that the weight ratio of metal platinum to the carrier is 1:99. The prepared catalyst is Pt / SiC, a platinum catalyst supported on porous nano-silicon carbide.

Embodiment 3

[0055] Example 3 Preparation of Porous Nano-Silicon Carbide Supported Platinum Catalyst 5Pt / SiC

[0056] The operation steps and conditions are the same as in Example 1, except that the weight ratio of metal platinum to the carrier is 1:19. The number of the prepared catalyst is 5Pt / SiC.

[0057] Table 1 Parameters of porous nano-silicon carbide supported platinum catalyst

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com