Starch modified filler and preparation method thereof

A technology of starch modification and starch, which is applied in the field of papermaking, can solve the problems of not being able to significantly improve the tear index and tensile index of paper, and achieve good application prospects, simple and easy-to-use process formula, and the effect of increasing whiteness and opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

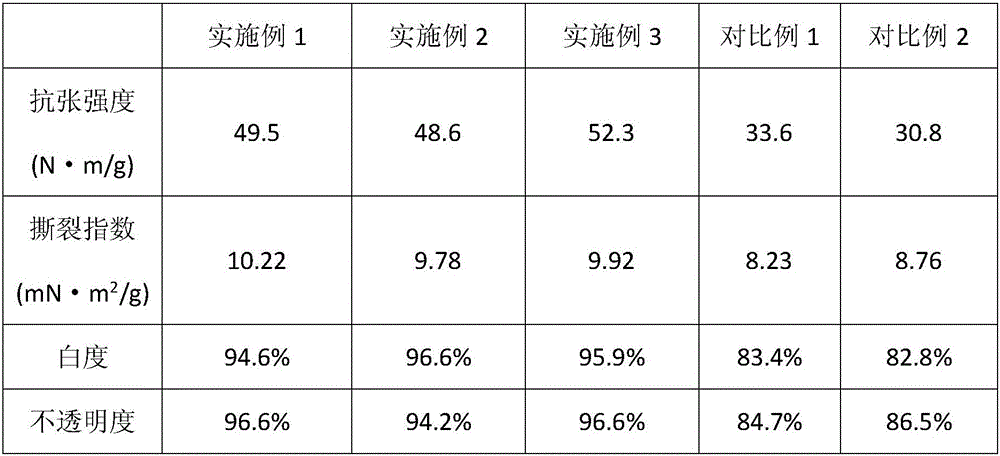

Examples

Embodiment 1

[0021] It consists of the following components in parts by weight: 20 parts of modified starch, 10 parts of modified zeolite, 5 parts of titanium alloy powder, 1 part of polyacrylamide, 1 part of sodium dodecylsulfonate, polystyrene and silicon 1 part of calcium acid calcium acid mixture with a weight ratio of 1:1.

[0022] The preparation method of modified starch is as follows: Weigh 10 parts by weight of starch and pour it into a container, add 10 parts by weight of distilled water, heat while stirring, add Span-80 after gelatinization is sufficient, stir and dissolve evenly, then add periodic acid Sodium solution, react for 4 hours, add ether to the mixture, stir for 5 minutes, then add sodium chloride, mix well, add ethanol to precipitate precipitate, separate and purify the precipitate, and obtain modified starch after drying.

[0023] The preparation method of the modified zeolite is as follows: the zeolite is ground into a 300-mesh powder, soaked in lactic acid for 6 h...

Embodiment 2

[0029] It consists of the following components in parts by weight: 40 parts of modified starch, 30 parts of modified zeolite, 15 parts of titanium alloy powder, 5 parts of methylurea, 3 parts of sodium dodecylsulfonate, polystyrene and silicon 3 parts of calcium acid calcium acid mixture with a weight ratio of 1:1.

[0030] The preparation method of modified starch is as follows: Weigh 10 parts by weight of starch and pour it into a container, add 10 parts by weight of distilled water, heat while stirring, add Span-80 after gelatinization is sufficient, stir and dissolve evenly, then add periodic acid Sodium solution, react for 4 hours, add ether to the mixture, stir for 5 minutes, then add sodium chloride, mix well, add ethanol to precipitate precipitate, separate and purify the precipitate, and obtain modified starch after drying.

[0031] The preparation method of the modified zeolite is as follows: the zeolite is ground into a 300-mesh powder, soaked in lactic acid for 6 h...

Embodiment 3

[0037] It consists of the following components in parts by weight: 30 parts of modified starch, 20 parts of modified zeolite, 10 parts of titanium alloy powder, 3 parts of glyoxal, 3 parts of sodium dodecylsulfonate, polystyrene and calcium silicate 1 part of the mixture with a weight ratio of 1:1.

[0038] The preparation method of modified starch is as follows: Weigh 10 parts by weight of starch and pour it into a container, add 10 parts by weight of distilled water, heat while stirring, add Span-80 after gelatinization is sufficient, stir and dissolve evenly, then add periodic acid Sodium solution, react for 4 hours, add ether to the mixture, stir for 5 minutes, then add sodium chloride, mix well, add ethanol to precipitate precipitate, separate and purify the precipitate, and obtain modified starch after drying.

[0039] The preparation method of the modified zeolite is as follows: the zeolite is ground into a 300-mesh powder, soaked in lactic acid for 6 hours at 50° C., a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com