Anti-impact toughened glass insulator and manufacturing method thereof

A technology of glass insulators and manufacturing methods, applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve the problems of destroying the tempering effect and surface compressive stress, high brittleness, poor mechanical properties, etc., to reduce notch sensitivity, anti-corrosion Strong impact ability and improved body toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

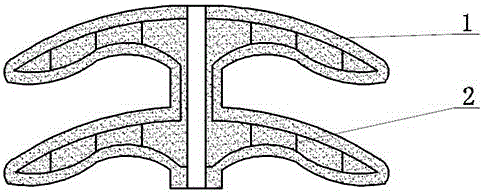

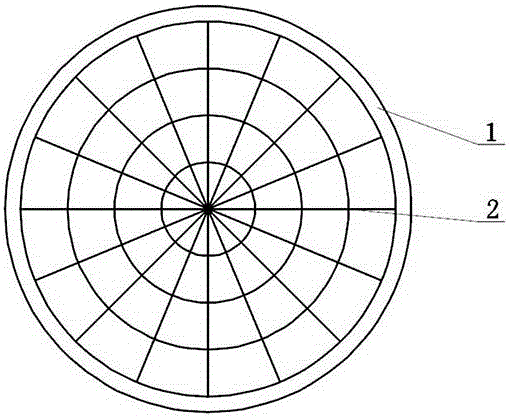

[0030] An impact-resistant toughened glass insulator, comprising a glass body 1 and a stainless steel wire mesh basket 2, wherein the raw materials of the glass body 1 include: 70 parts of silicon dioxide, 8 parts of calcium oxide, 10 parts of sodium carbonate, 3 parts of magnesium oxide, and 1 part of phosphorus 1 part, carbon 1 part; the stainless steel wire mesh basket 2 is made of stainless steel wire with a diameter of 0.05mm, and its three-dimensional outline size is 20mm less than the three-dimensional outline size of the insulator.

[0031] The manufacturing method of the impact-resistant toughened glass insulator includes the following steps:

[0032] 1) Preparation before production

[0033] ① The glass body 1 raw material includes the following components in parts by weight: 70 parts of silicon dioxide, 8 parts of calcium oxide, 10 parts of sodium carbonate and 3 parts of magnesium oxide powder;

[0034] ② Functional auxiliary materials include the following compon...

Embodiment 2

[0050] An impact-resistant and toughened glass insulator, comprising a glass body 1 and a stainless steel wire mesh basket 2, wherein the raw materials of the glass body 1 include: 80 parts of silicon dioxide, 10 parts of calcium oxide, 15 parts of sodium carbonate, 5 parts of magnesium oxide, and 2 parts of phosphorus 2 parts, carbon 2 parts; stainless steel wire mesh basket 2 is made of stainless steel wire with a diameter of 0.1mm, and its three-dimensional outline size is 30mm less than the three-dimensional outline size of the insulator.

[0051] The manufacturing method of the impact-resistant toughened glass insulator includes the following steps:

[0052] 1) Preparation before production

[0053] ① The glass body 1 raw material includes the following components in parts by weight: 80 parts of silicon dioxide, 10 parts of calcium oxide, 15 parts of sodium carbonate and 5 parts of magnesium oxide powder;

[0054] ② Functional auxiliary materials include the following co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com