Method for preparing metal oxide thin-film resistive random access memory through plasma processing

A technology of oxide thin film and resistive memory, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems affecting the stability of device performance, long response time, low efficiency, etc., and achieve good consistency and integration High density and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

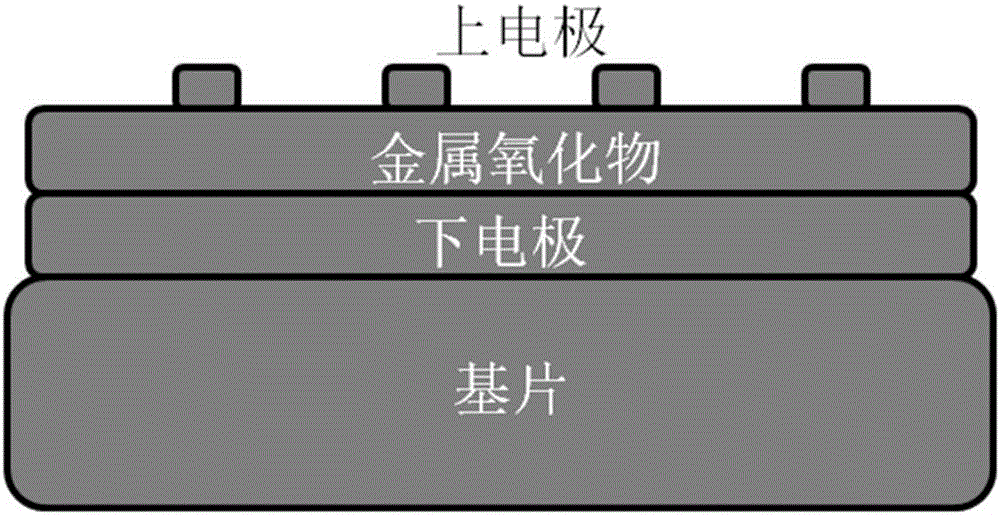

[0030] Concrete implementation steps of the present invention:

[0031] Step 1: Prepare a metal thin film electrode on a silicon substrate. The substrate is a commercially purchased silicon substrate with a P-doped 110 crystal plane.

[0032] Step 2: Deposit the lower electrode metal film. Platinum was chosen as the metal of the lower electrode in the experiment, and it was prepared directly on the silicon substrate by magnetron sputtering. After the sample is placed in the sputtering chamber, the vacuum is evacuated to a pressure of 6×10-4Pa. Argon gas is then introduced and a DC voltage is applied between the chamber and the target. The target is a disk-shaped metal block made of metal platinum. When the voltage reaches 420 volts, a certain concentration of argon plasma is generated. Under this condition, the sputtering rate of platinum is about 12 nanometers per minute, and the sputtering time is 8 minutes, so the thickness of the obtained metallic platinum is about 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com