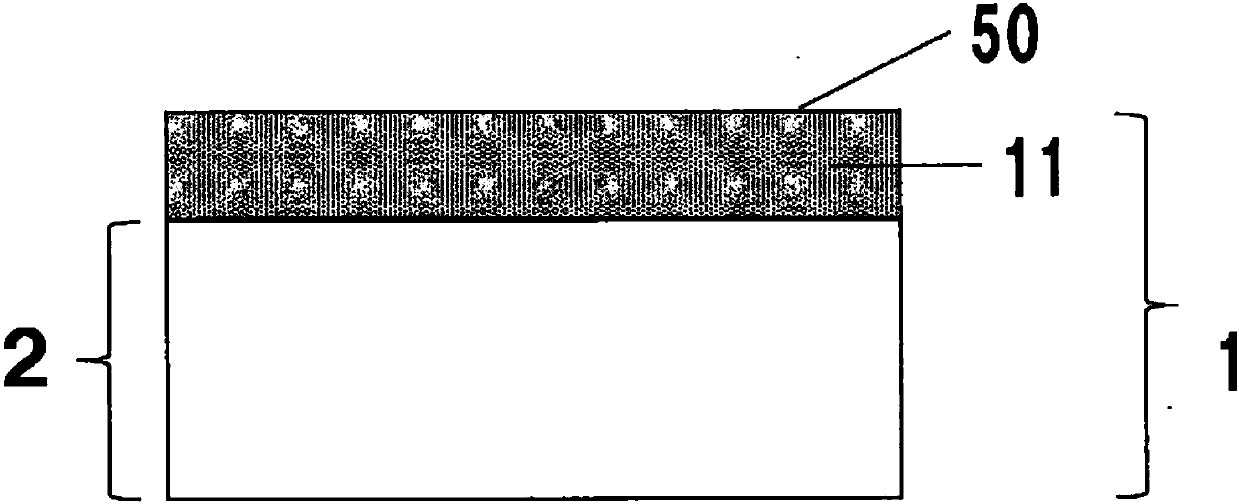

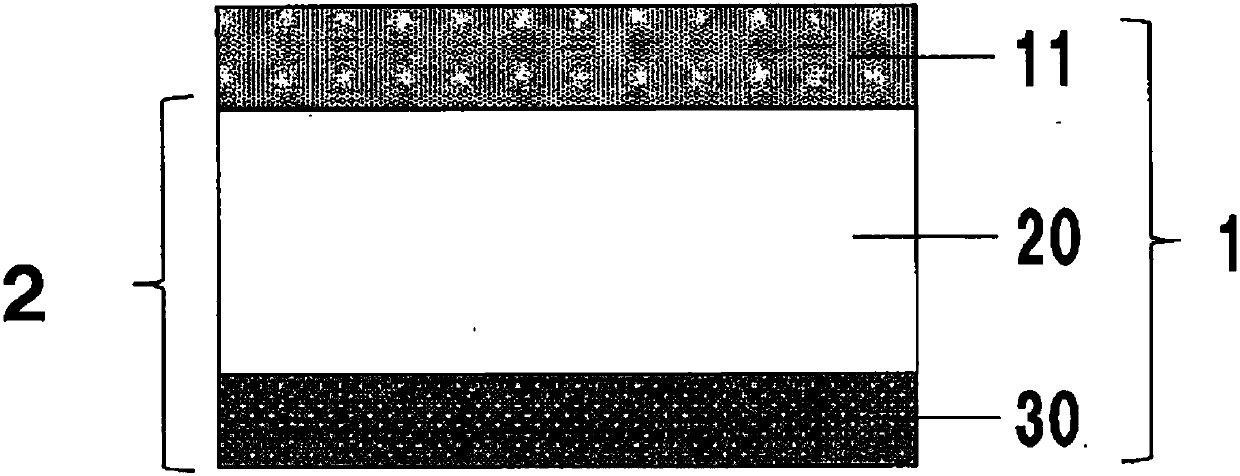

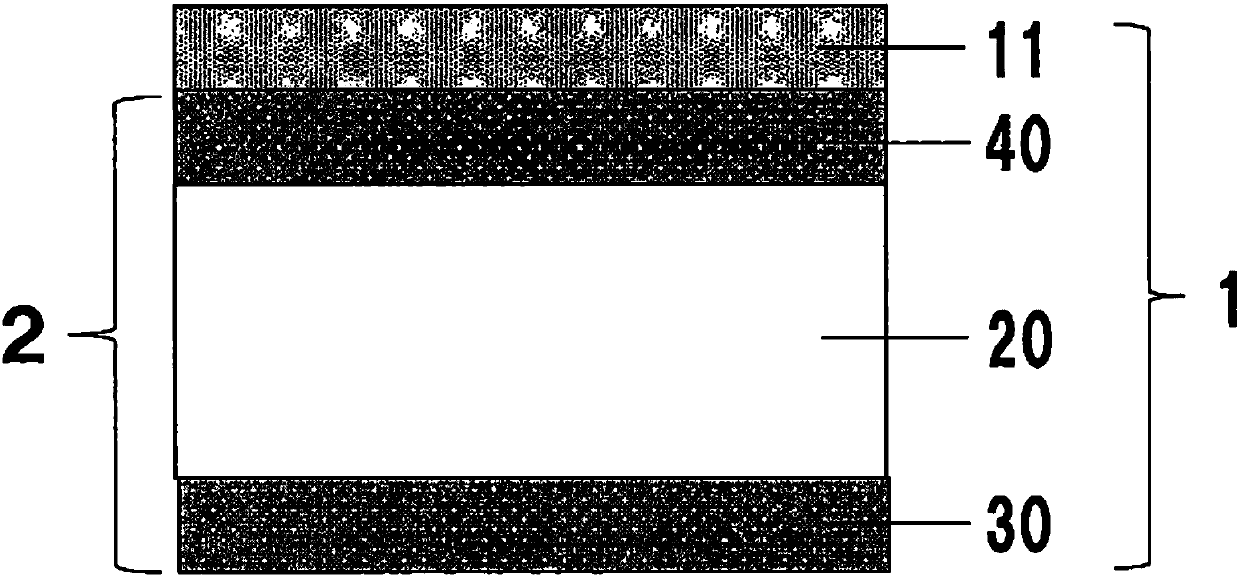

Solar battery backplane and solar battery module

A technology for solar cells and back sheets, applied in circuits, electronic equipment, photovoltaic power generation, etc., can solve problems such as molecular weight reduction and mechanical property reduction, and achieve the effects of excellent interface bonding strength, excellent bonding strength, and excellent protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0212] The PET polymer e shown in Table 1 was used as the raw material for forming the A layer, and the PET polymer k was used as the raw material for the B layer, and they were laminated by a lamination device in such a way that they became the B layer / A layer. The die forms the sheet. The lamination structure is as shown in Table 2. The thickness of the layer A is 50 μm, the thickness of the layer B is 200 μm, and the total thickness is 250 μm. Thickness is controlled by adjustment of extruder discharge. The unstretched sheet that cools and solidifies the sheet-shaped molded product discharged from the T die through the cooling roller with a surface temperature of 25°C is guided to the roller group heated to 85-98°C, and stretched longitudinally 3.3 times along the long side direction, Cooling is performed using a roll set at 21 to 25°C. Next, the longitudinally stretched film was guided to a tenter while clamping both ends of the longitudinally stretched film, and was lat...

Embodiment 2~5

[0215] A base film made of a biaxially stretched polyester film was produced in the same manner as in Example 1, except that the PET polymer raw materials shown in Table 2 were used respectively, and the A layer and the B layer had a predetermined thickness. Then, solar battery back sheets BS2 to BS5 having the laminated structure shown in Table 2 were produced in the same manner as in Example 1.

Embodiment 6

[0217] Using the PET polymer raw materials shown in Table 2, a base film made of a biaxially stretched polyester film was produced in the same manner as in Example 1 so that the A layer and the B layer had a predetermined thickness.

[0218] Next, the C layer-forming raw material composition C5 was applied on the surface of the B layer of the substrate film using a metal wire bar, dried at 180° C. for 60 seconds, and the C layer was provided so that the coating thickness after drying became 0.5 μm. . By aging the sheet thus obtained at 40° C. for 3 days, a solar battery back sheet BS6 having a laminated structure shown in Table 2 was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com