Modification method for processing membrane artificial lung surface by low-temperature plasma and grafting polyfluoride

A low-temperature plasma and plasma technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem of poor biocompatibility of polymer membranes, injection of a large amount of anticoagulant, inability to completely inhibit human rejection, etc. problems, to achieve the effects of excellent carrying capacity, broad medical application prospects, and excellent gas transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

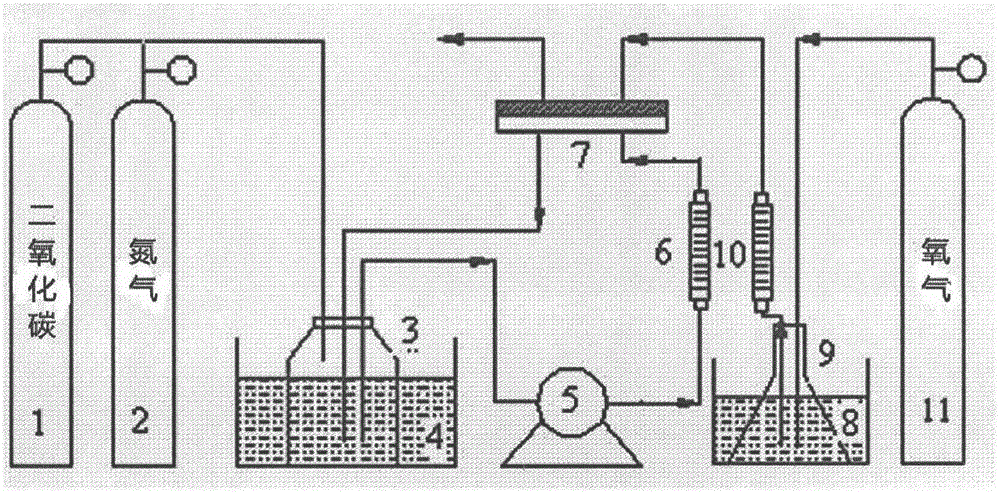

Method used

Image

Examples

specific Embodiment 1

[0022] Soak the poly-4-methyl-1-pentene hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor to fix it, and vacuum it To 1Pa, oxygen is introduced for surface activation. The air pressure in the cavity is 30Pa, the irradiation power is 150W, and the irradiation time is 210s. Stop the discharge, evacuate the vacuum chamber to 1Pa, replace the gas in the chamber with nitrogen, repeat three times;

[0023] The treated poly-4-methyl-1-pentene hollow fiber membrane was taken out, and soaked in 1H, 1H, 2H-perfluoro-1-hexene for 6 hours at a constant temperature of 10°C. Take out the poly-4-methyl-1-pentene hollow fiber membrane, wash it with deionized water, and dry it in a vacuum oven;

[0024] The hollow fiber membrane obtained above was fixed in the chamber of a plasma processor, vacuumed to 1 Pa, and helium gas was introduced to carry out graft curing. The air pressu...

specific Embodiment 2

[0025] Soak the poly-4-methyl-1-pentene hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor to fix it, and vacuum it To 1Pa, oxygen is introduced for surface activation. The air pressure in the cavity is 20Pa, the irradiation power is 100W, and the irradiation time is 180s. Stop the discharge, evacuate the vacuum chamber to 1Pa, replace the gas in the chamber with nitrogen, repeat three times;

[0026] The treated poly-4-methyl-1-pentene hollow fiber membrane was taken out and soaked in perfluorohexylethylene for 12 hours at a constant temperature of 10°C. Take out the poly-4-methyl-1-pentene hollow fiber membrane, wash it with deionized water, and dry it in a vacuum oven;

[0027] The hollow fiber membrane obtained above was fixed in the chamber of a plasma processor, vacuumed to 1 Pa, and helium gas was introduced to carry out graft curing. The air pressure in t...

specific Embodiment 3

[0028]Soak the poly-4-methyl-1-pentene hollow fiber membrane in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried hollow fiber membrane into the chamber of the plasma processor to fix it, and vacuum it To 1Pa, oxygen is introduced for surface activation. The air pressure in the cavity is 30Pa, the irradiation power is 200W, and the irradiation time is 240s. Stop the discharge, evacuate the vacuum chamber to 1Pa, replace the gas in the chamber with nitrogen, repeat three times;

[0029] The treated poly-4-methyl-1-pentene hollow fiber membrane was taken out and soaked in 1H, 1H, 2H-perfluoro-1-decene for 18 hours at a constant temperature of 10°C. Take out the poly-4-methyl-1-pentene hollow fiber membrane, wash it with deionized water, and dry it in a vacuum oven;

[0030] The hollow fiber membrane obtained above was fixed in the chamber of a plasma processor, vacuumed to 1 Pa, and helium gas was introduced to carry out graft curing. The air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com