Preparation method of hydroxyl arsenic ferrous phosphate solid solution and application of method

A hydroxyarsenic ferrous phosphate, ferrous phosphate technology, applied in chemical instruments and methods, water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor stability of arsenic compounds and environmental pollution, and achieve stable Good properties, long-term storage stability, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

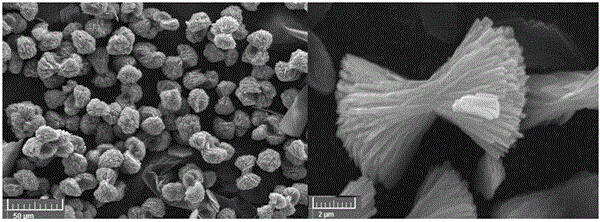

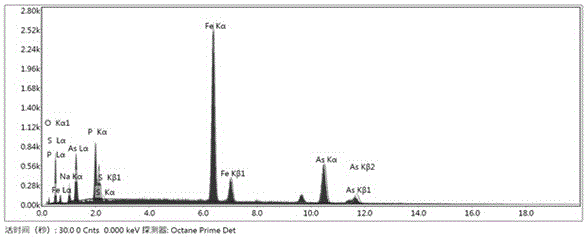

Examples

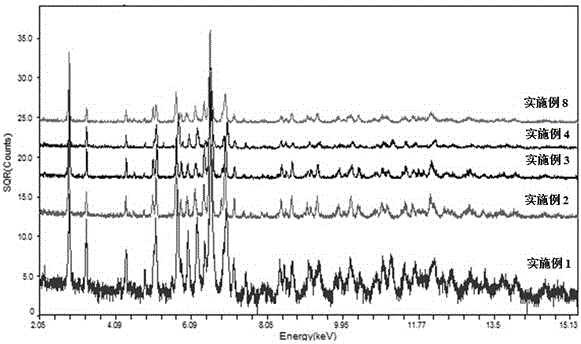

Embodiment 1

[0023] Under the condition of stirring at room temperature, add 2.54 g of sodium arsenate solid into a beaker containing 50 mL of deionized water to prepare an arsenic solution (the molar concentration of sodium arsenate is 0.120 mol L -1 ); while stirring at room temperature, add 5.60 g of ferrous sulfate heptahydrate to a beaker containing 100 mL of deionized water (the molar concentration of ferrous sulfate is 0.201 mol L -1 ) and 7.95g phosphoric acid solution (the mass fraction of phosphoric acid is 85%, the molar concentration of phosphoric acid is 0.690mol L -1 ), to prepare the ferrous hydroxyphosphate precursor solution; add the arsenic solution dropwise to the ferrous hydroxyphosphate precursor solution while stirring, and use 1.00mol / L NaOH to adjust the initial pH value of the reaction system during the mixing process, so that the reaction system The initial pH value is maintained in the range of 7.90 to 8.10. After fully stirring for 30 minutes, pour it into a hyd...

Embodiment 2

[0025] Under the condition of stirring at room temperature, add 4.17 g of sodium arsenate solid into a beaker containing 50 mL of deionized water to prepare an arsenic solution (the molar concentration of sodium arsenate is 0.197 mol L -1 ); while stirring at room temperature, simultaneously add 0.25 g of ferrous sulfate heptahydrate to a beaker containing 100 mL of deionized water (the molar concentration of ferrous sulfate is 0.009 mol L -1 ) and 3.13g phosphoric acid (the mass fraction of phosphoric acid is 85%, and the molar concentration of phosphoric acid is 0.271mol L -1 ), to prepare the ferrous phosphate precursor solution; add the arsenic solution dropwise to the ferrous phosphate precursor solution while stirring, and use 1.00mol / L NaOH to adjust the initial pH value of the reaction system during the mixing process, so that the initial pH value of the reaction system The value is maintained in the range of 7.90 to 8.10. After fully stirring for 60 minutes, pour it i...

Embodiment 3

[0027] Under the condition of stirring at room temperature, add 4.17 g of sodium arsenate solid into a beaker containing 50 mL of deionized water to prepare an arsenic solution (the molar concentration of sodium arsenate is 0.197 mol L -1 ); while stirring at room temperature, add 2.12 g of ferrous sulfate heptahydrate to a beaker containing 100 mL of deionized water (the molar concentration of ferrous sulfate is 0.076 mol L -1 ) and 0.52g phosphoric acid (the mass fraction of phosphoric acid is 85%, and the molar concentration of phosphoric acid is 0.045mol L -1), to prepare the ferrous phosphate precursor solution; add the arsenic solution dropwise to the ferrous phosphate precursor solution while stirring, and use 1.00mol / L NaOH to adjust the initial pH value of the reaction system during the mixing process, so that the initial pH value of the reaction system The value is maintained in the range of 7.90 to 8.10. After fully stirring for 100 minutes, pour it into a hydrother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com