Antibacterial antistatic emulsion and coating and their preparation method

An anti-static, emulsion technology, applied in conductive coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of anti-bacterial, anti-static function reduction, pollution, and environmental aggravation of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

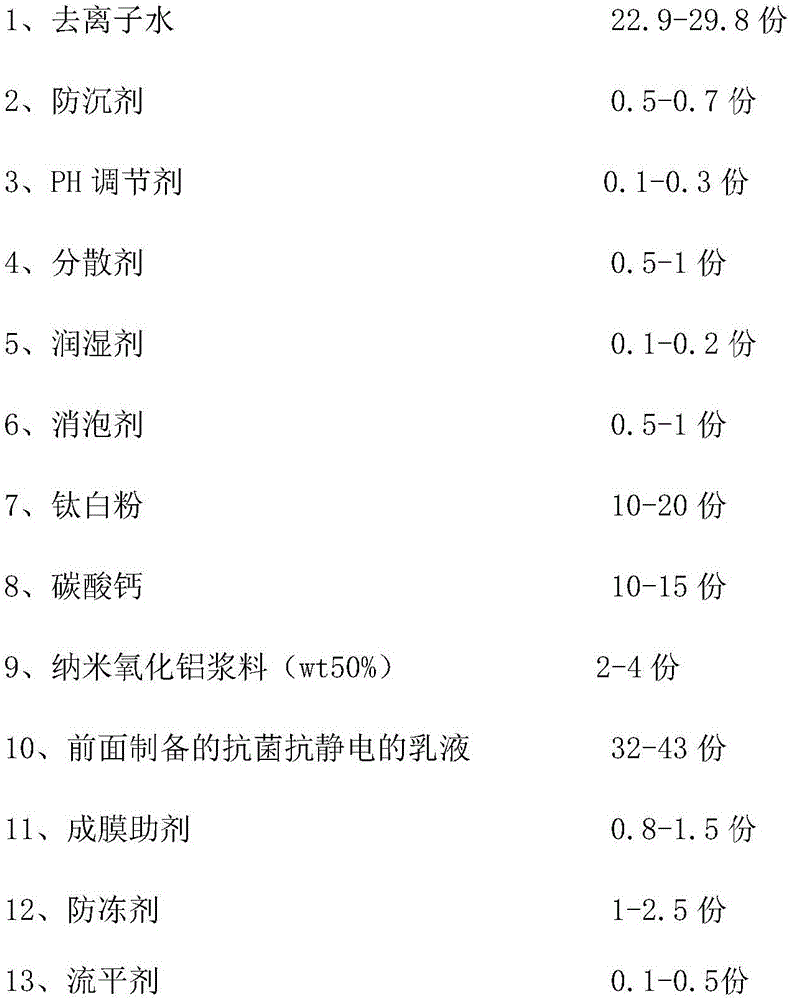

Examples

Embodiment 1

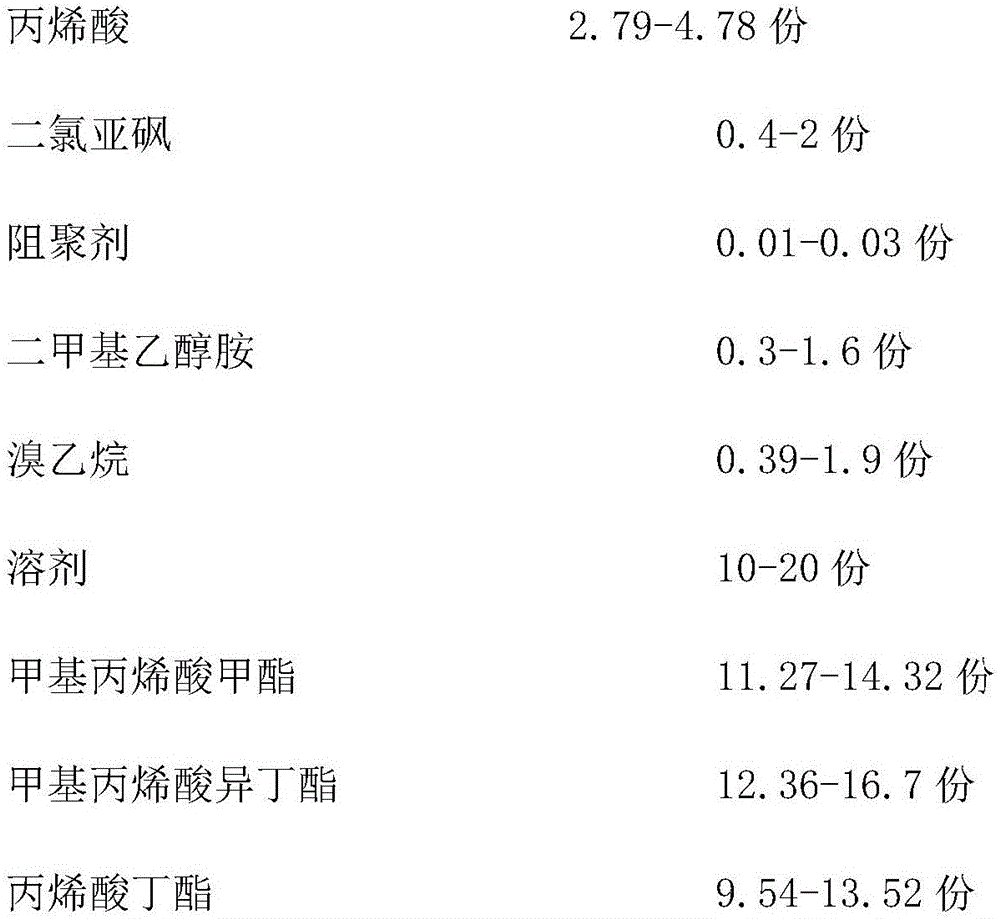

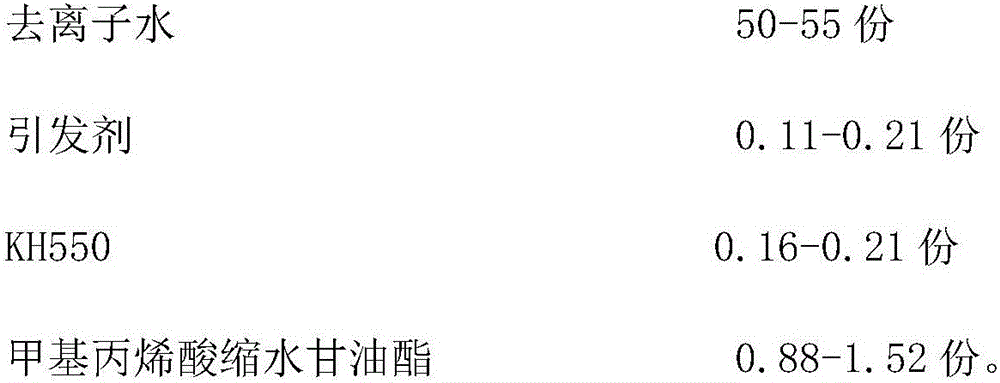

[0043] 1. The antibacterial emulsion is prepared from the raw materials in the following weight ratio according to the following steps:

[0044]

[0045] The preparation of antibacterial and antistatic emulsion includes two parts: the synthesis of acryloyloxyethyl dimethyl ethyl ammonium bromide and the synthesis of antibacterial and antistatic emulsion

[0046] (1) Synthesis of functional monomer acryloyloxyethyl dimethyl ethyl ammonium bromide

[0047] ① Preparation of Acryloyl Chloride

[0048] In a three-neck flask equipped with a condenser, a thermometer and a dropping funnel, add thionyl chloride and a small amount of polymerization inhibitor. At room temperature, add 0.2 parts of refined acrylic acid monomer dropwise under magnetic stirring at 300 rpm. Raise the temperature to 35°C, react for 3 hours, cool to room temperature, and distill under reduced pressure to prepare acryloyl chloride.

[0049] ② Preparation of dimethylaminoethyl acrylate

[0050] Add dimethy...

Embodiment 2

[0062] 1. The antibacterial emulsion is prepared from the raw materials in the following weight ratio according to the following steps:

[0063]

[0064]

[0065] The preparation of antibacterial and antistatic emulsion includes two parts: the synthesis of acryloyloxyethyl dimethyl ethyl ammonium bromide and the synthesis of antibacterial and antistatic emulsion.

[0066] (1) Synthesis of functional monomer acryloyloxyethyl dimethyl ethyl ammonium bromide

[0067] ① Preparation of Acryloyl Chloride

[0068] In a three-neck flask equipped with a condenser, a thermometer and a dropping funnel, add thionyl chloride and a small amount of polymerization inhibitor. At room temperature, add 1 part of refined acrylic acid monomer dropwise under magnetic stirring at 400 rpm, and the dropwise addition is completed. Raise the temperature to 40°C, react for 4 hours, cool to room temperature, and distill under reduced pressure to prepare acryloyl chloride.

[0069] ② Preparation of...

Embodiment 3

[0081]

[0082]

[0083] ① Preparation of Acryloyl Chloride

[0084] In a three-necked flask equipped with a condenser, a thermometer and a dropping funnel, add thionyl chloride and a small amount of polymerization inhibitor. At room temperature, add 1.2 parts of refined acrylic acid monomer dropwise under magnetic stirring at 500 rpm. Raise the temperature to 45°C, react for 5 hours, cool to room temperature, and distill under reduced pressure to prepare acryloyl chloride.

[0085] ② Preparation of dimethylaminoethyl acrylate

[0086] Add dimethylethanolamine, 10 parts of solvent and a small amount of polymerization inhibitor sequentially into the three-necked flask, slowly add acryloyl chloride dropwise under ice-water bath at 500 rpm under magnetic stirring, and keep reacting under ice-water bath for 4 hours after the dropwise addition. After the reaction is completed, filter the mixed solution in the bottle, and distill the obtained filtrate under reduced pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com