A kind of sulfonated polyether ether ketone that can be used as cross-linked proton exchange membrane material and its preparation method and application

A technology of sulfonated polyether ether ketone and proton exchange membrane, applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of high cost, many steps, and difficulty in large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

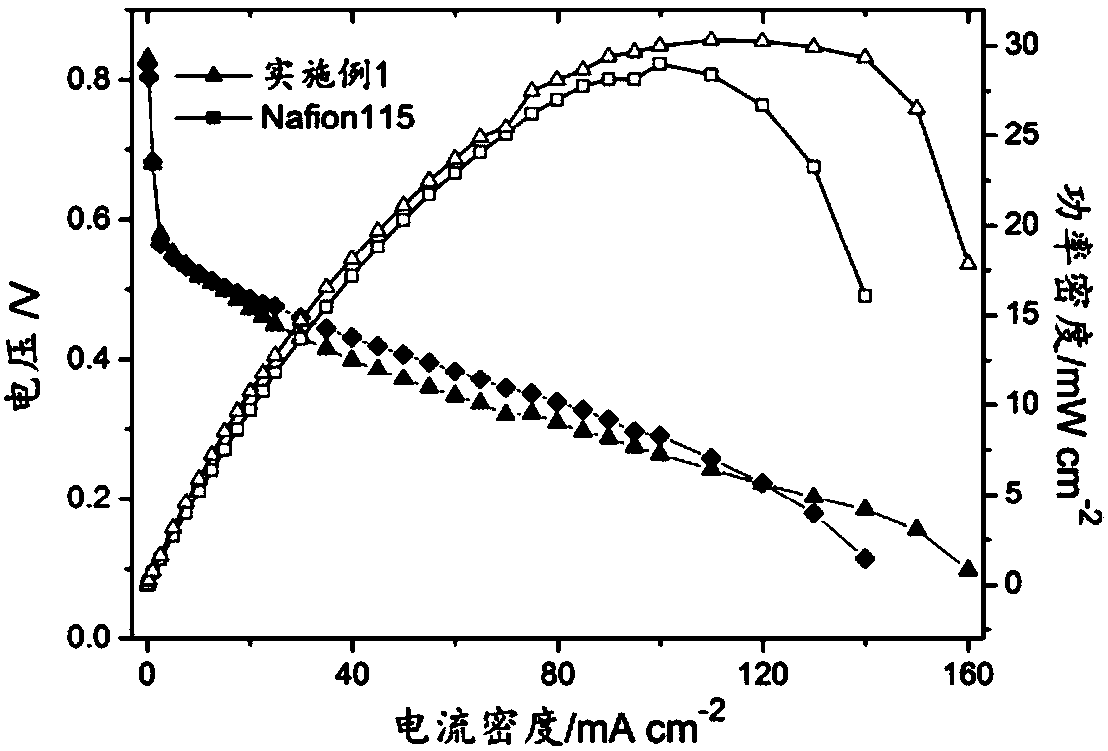

Embodiment 1

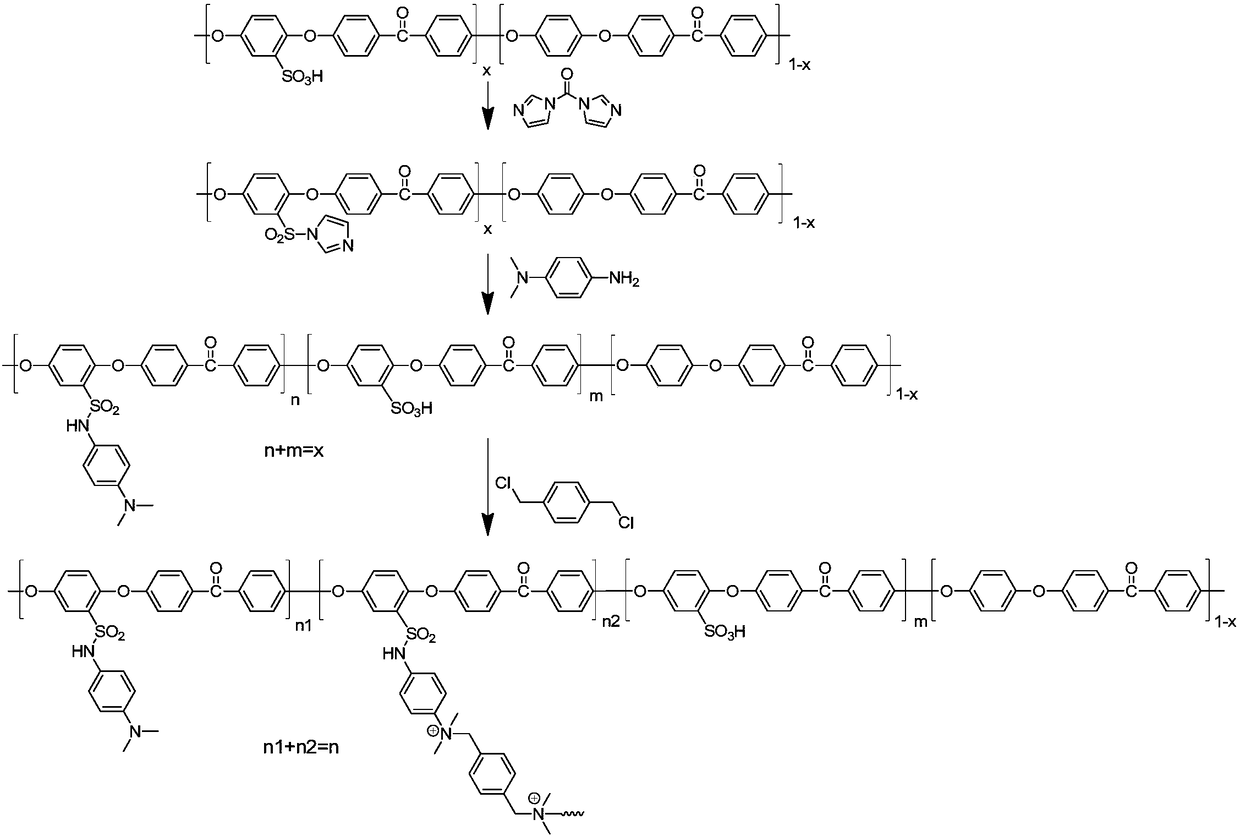

[0071] (1) Dissolve 10.00g of sulfonated polyetheretherketone (60% sulfonation degree) in 100mL of DMSO, add 1.46g of CDI, react at 50°C for 2h, then add 1.23g of N,N-dimethyl-p-phenylenediamine , after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 50%;

[0072] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.06 g of α,α’-dichloroxylene and stir at 25°C for 2 hours to obtain a casting solution;

[0073] (3) Cast the above casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 120°C for heat treatment for 12 hours to obtain protons with a degree of crosslinking (covalent) of 10%. exchange membrane, the synthetic route is as follows figure 1 Shown, where x=0.6, n 1 =0.27, n 2 = 0....

Embodiment 2

[0075](1) Dissolve 10.00g of sulfonated polyether ether ketone (40% sulfonation degree) in 100mL DMSO, add 1.01g of CDI, react at 50°C for 2h, then add 0.64g of N,N-dimethyl-1,3 -Propylenediamine, after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 47%;

[0076] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.24 g of α,α’-dibromoxylene, stir at 25° C. for 2 h to obtain a casting solution;

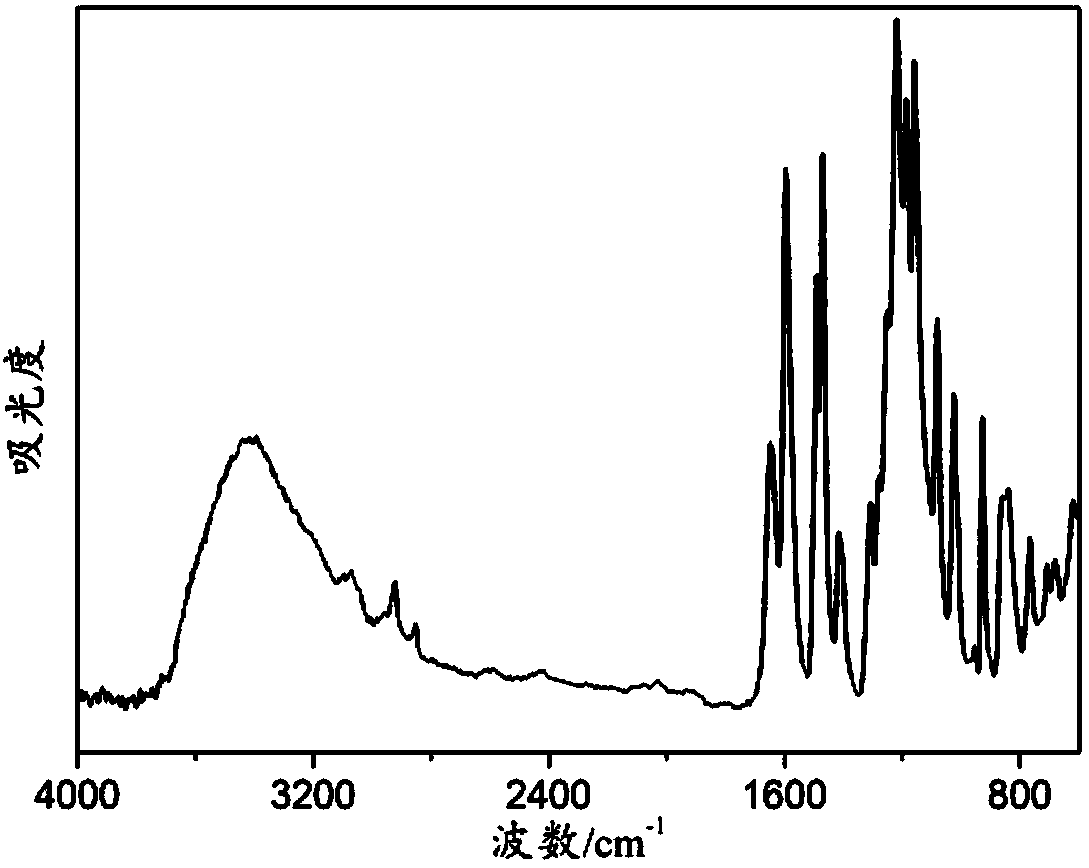

[0077] (3) Cast the above-mentioned casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 110°C for heat treatment for 12 hours to obtain a proton exchange membrane with a crosslinking degree of 40%. Infrared spectrum test shows that the polymer structure obtained in this embodiment contains ca...

Embodiment 3

[0079] (1) Dissolve 10.00g of sulfonated polyether ether ketone (sulfonation degree 60%) in 100mL DMSO, add 1.46g of CDI, react at 50°C for 2h, then add 1.05g of N,N-dimethyl-1,4 -Butanediamine, after reacting at 50°C for 3 hours, sink the polymer into water, filter with suction, collect the filter cake, wash with water, and dry to obtain tertiary aminated sulfonated polyetheretherketone with a grafting rate of 42%;

[0080] (2) Dissolve 8.00 g of the above-mentioned tertiary aminated sulfonated polyetheretherketone in 100 mL of DMSO, add 0.44 g of α,α’-dibromoxylene, stir at 25° C. for 2 h to obtain a casting solution;

[0081] (3) Cast the above casting solution on a glass plate, bake in a blast oven at 60°C for 8 hours, and finally place it in a vacuum oven at 100°C for heat treatment for 12 hours to obtain a proton exchange membrane with a crosslinking degree of 60%. Infrared spectrum test shows that the polymer structure obtained in this embodiment contains carbonyl, meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com