A kind of Ga-doped ZNO nano-ink and preparation method thereof

A nano-ink and co-doping technology, which is applied in inks, household utensils, applications, etc., can solve the problems of low performance of doped ZnO, deterioration of device performance, etc., and achieve the effect of simple and easy synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

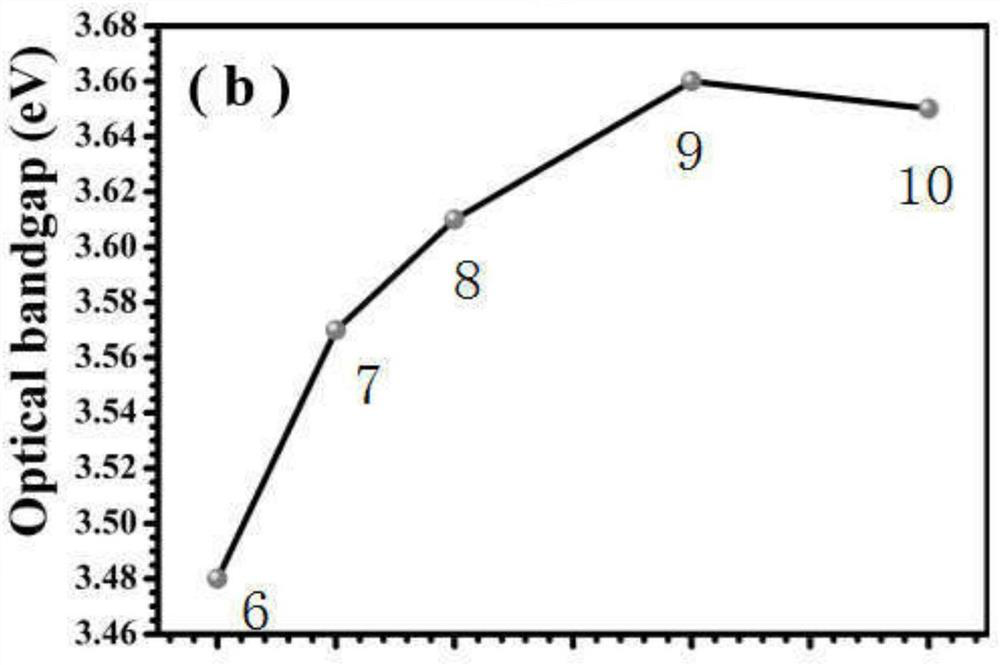

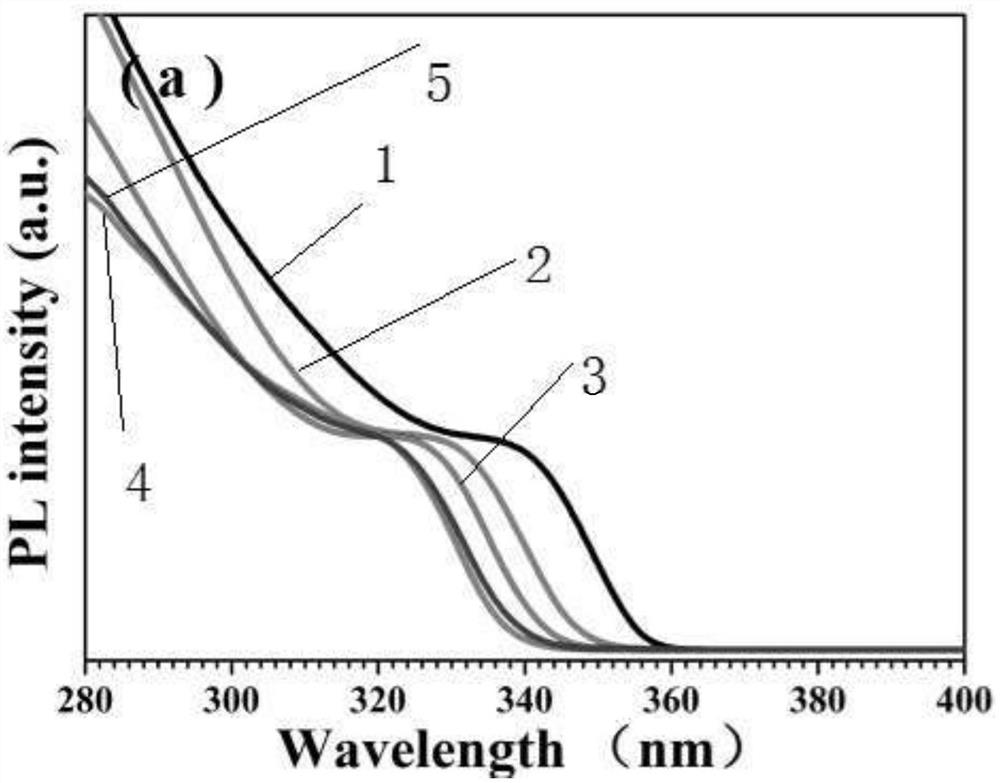

[0032] Weigh 0.3mmol of zinc acetate dihydrate and 0.003mmol of gallium acetate into 30ml of dimethyl sulfoxide, heat up to 30°C, stir magnetically for 4min, stir evenly, add 0.3mol / L ethanol alkali solution (tetramethylsulfoxide) Ammonium hydroxide dissolved in ethanol) 10ml, stirred and reacted at 30°C for 1 hour. Add 70 ml of acetone, centrifuge at 2000 rpm for 3 min, dissolve in ethanol solution, and obtain doped ZnO nanoparticle ink.

Embodiment 2

[0034] Weigh 0.3mmol of zinc acetate dihydrate and 0.006mmol of gallium acetate into 30ml of dimethyl sulfoxide, heat up to 20-50°C, stir magnetically for 8min, stir evenly, add 0.5mol / L ethanol alkali solution ( Tetramethylammonium hydroxide (dissolved in ethanol) 10ml, stirred and reacted at 30°C for 1 hour. Add 75 ml of acetone, centrifuge at 3000 rpm for 3-5 min, dissolve in ethanol solution, and obtain doped ZnO nano particle ink.

Embodiment 3

[0036] Weigh 0.3mmol of zinc acetate dihydrate and 0.024mmol of gallium acetate into 30ml of dimethyl sulfoxide, heat up to 20-50°C, stir magnetically for 10min, stir evenly, add 0.8mol / L ethanol alkali solution ( Tetramethylammonium hydroxide (dissolved in ethanol) 10ml, stirred and reacted at 30°C for 1 hour. Add 70 ml of acetone, centrifuge at 2000 rpm for 5 min, dissolve in ethanol solution, and obtain doped ZnO nanoparticle ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

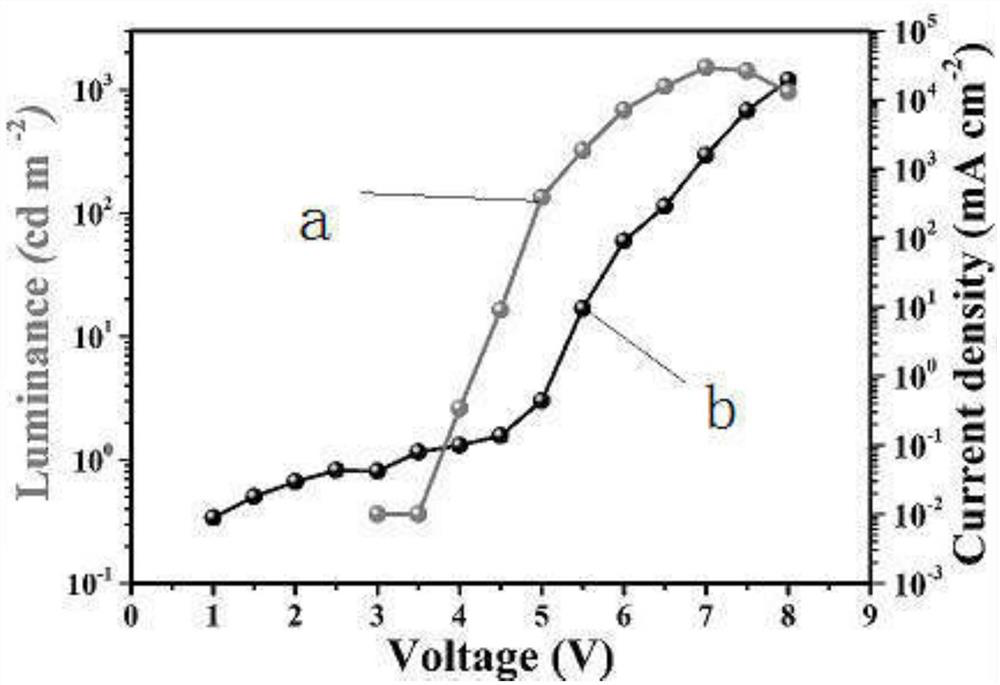

| luminance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com